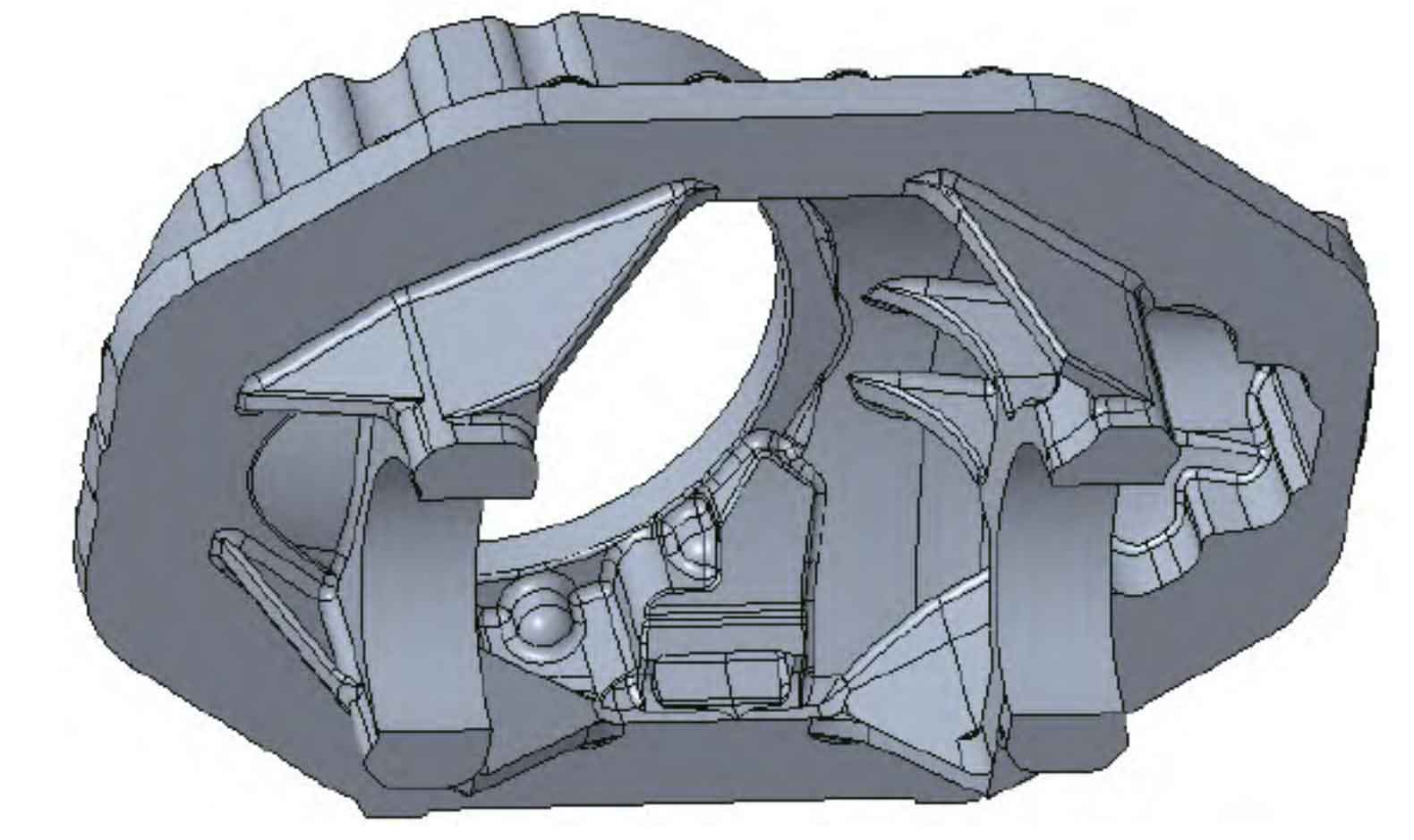

The split main reducer housing casting is the main reducer housing of the middle and rear axle of the Benz series imported from Germany at the end of the last century in China. Since its introduction, this product has existed for a long time in the main heavy truck models in China, and the market demand is stable. There are only small size differences between the series products of different heavy truck models. With the development of automobile technology, the product quality requirements are gradually improved. Recently, the requirements of newly developed customers for this product are: shrinkage cavity and shrinkage porosity casting defects are not allowed. Therefore, by dissecting the products produced by the current process, confirm the shrinkage and porosity of the products, and provide reference for developing new products to optimize the casting process plan.

For the heavy truck split main reducer shell casting, the shrinkage cavity and shrinkage porosity of the isolated hot joint can be effectively solved by setting a riser near the hot joint; The cold riser shall be set at the isolated hot spot far away from the riser feeding area, and the heating riser sleeve shall be added outside the cold riser to effectively improve the feeding efficiency of the riser, thus solving the shrinkage cavity and shrinkage porosity casting defects, improving the internal quality of the casting, and meeting the customer’s improved product quality requirements.