1. Pre simulation processing

After completing the drawing of the sand casting pouring system, ProCAST software is used to divide the shell into grids and select appropriate grid steps to ensure accurate total time and simulation results in the numerical simulation analysis process. Import sand castings on the Visual Mesh work page, set the mesh step size of the sand castings to 30mm, and divide a total of 12722 face grids and 45906 body grids. Using Mesh’s Check process from 1D, 2D, and 3D, check the mesh division for cracks, intersections, damages, overlap, and mating surfaces. During the mesh division stage, comprehensively repair these defects and complete the establishment of the final volume mesh. In the pre-treatment stage, the sand casting material is set to Medium CarbonAISI1040 (ZG270-500), resin sand molding and core making, and the molding sand and core material are silicon sand. The temperature of the sand mold is 25 ℃, the cooling method is COINC, and the heat transfer coefficient between the metal and sand mold is 1000W/(m2 · K). Set parameters such as gravity acceleration, boundary conditions, and cooling method in sequence.

2. Simulation and Analysis of Metal Liquid Filling and Solidification Process

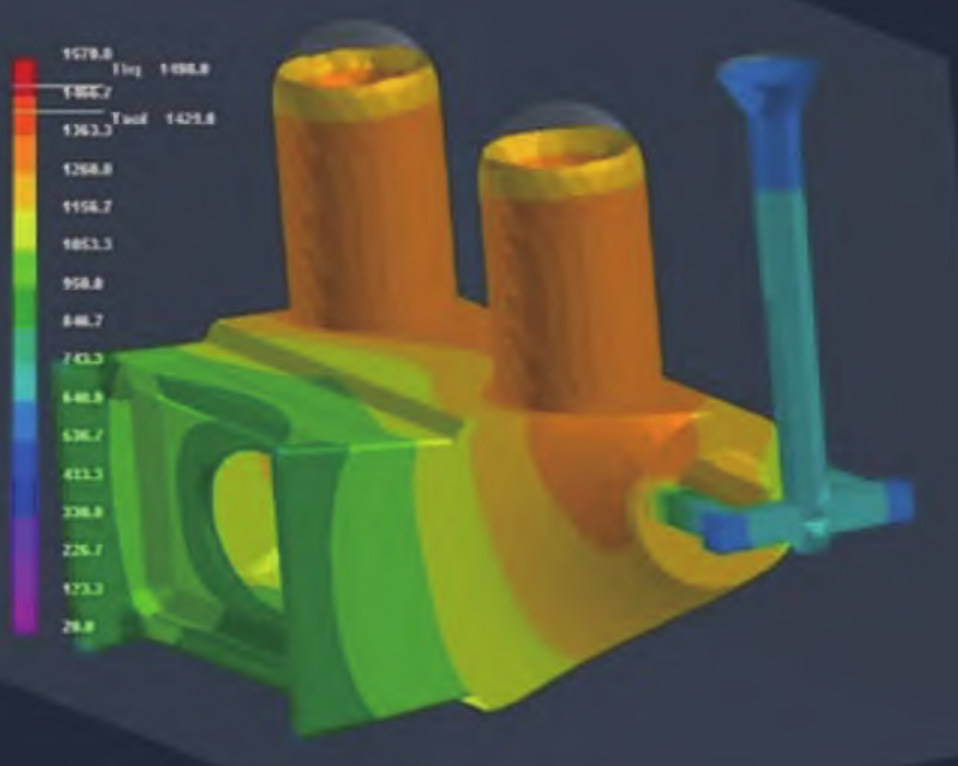

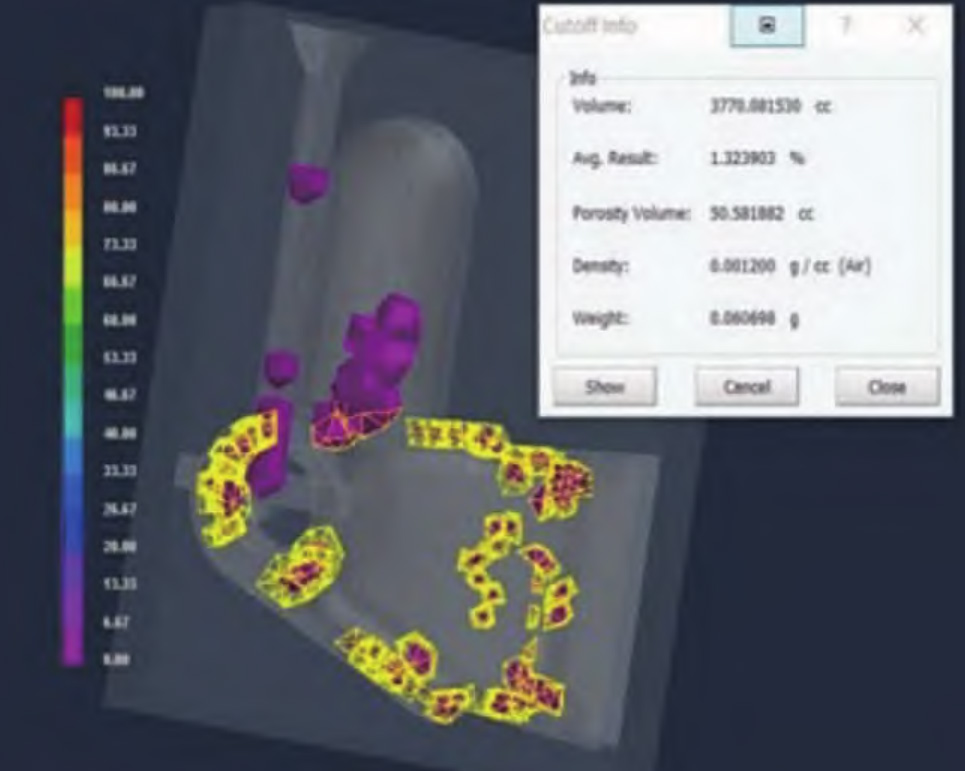

Set the pouring temperature of sand castings to 1560 ℃ and the pouring speed to 1.6m/s. After setting, use simulation software to simulate the two schemes, and the simulation results are shown in Figure 1 and Figure 2. From Figures 1 and 2, it can be seen that there is a defect of insufficient pouring above the cylindrical part of the shell. Therefore, two open risers were designed and simulated in the area of insufficient pouring. The temperature field of Scheme 1 is shown in Figure 3, and the pore distribution diagram is shown in Figure 4. The temperature field of Scheme 2 is shown in Figure 5, and the pore distribution diagram is shown in Figure 6. The pore volume of Scheme 1 is 28.23cm3, while Scheme 2 has a pore volume of 50.58cm3. Due to too many sand casting defects, the shell sand casting cannot be used.