For the convenience of analysis, this article only conducts defect analysis on a single investment casting. The pouring system structure of 304 stainless steel ball valve under traditional technology is a stepped pouring system, and the distribution of shrinkage porosity and shrinkage defects is shown in Figure 1.

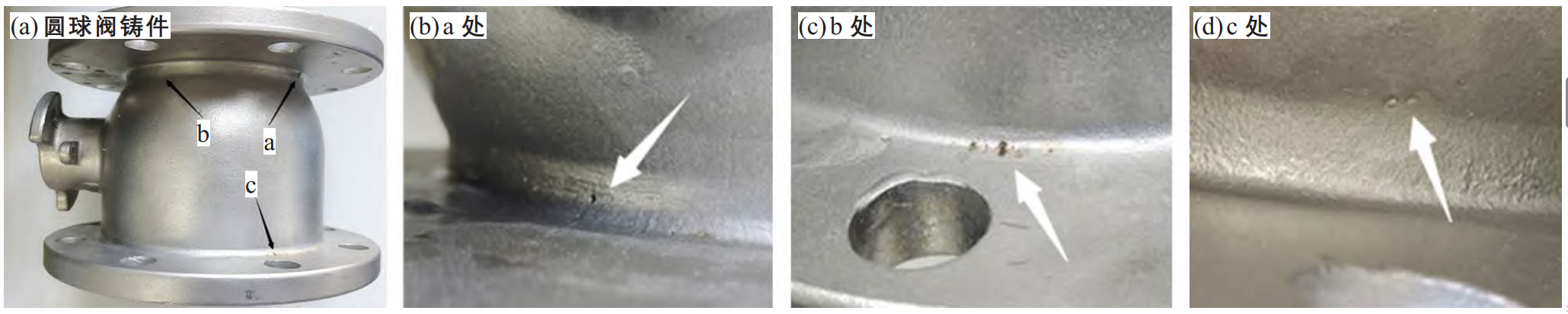

Through numerical simulation analysis, it can be seen that the maximum shrinkage porosity is 13.2%. When setting up a stepped pouring system according to the traditional plan, the shrinkage defects of investment castings are more obvious and generally distributed at the corners of the valve body and flange surface of the ball valve. This is due to the uneven wall thickness at the corners of the valve wall and the poor heat dissipation conditions in the concave areas of the investment castings, resulting in the metal liquid not solidifying in sequence. After the filling of the valve body is completed, the metal liquid in the mold cavity begins to solidify. The areas with more heat exchange between the valve body and the air at the corner of the valve body dissipate heat quickly and solidify first, while the areas with less heat exchange dissipate heat slowly solidify later. After solidification, the liquid is replenished to the areas that solidify first. However, it is difficult to replenish the liquid at the corner far from the inner gate, leading to the formation of shrinkage defects at the corner. The defects in traditional processes are mainly distributed in the shrinkage holes at the corners of the ball valve body and flange. In the actual production process using traditional solutions, the defects are also mainly distributed at the corners of the ball valve body and flange. The numerical simulation of the defects is basically consistent with the actual situation. The physical defect diagram of investment castings is shown in Figure 2.