Lost foam casting is a technique that is continually being explored for its vast potential in various sectors. This method can provide a more economical and efficient way of creating complex parts, which can lead to the development of new, innovative products. Here are some areas where the possibilities of lost foam casting are particularly exciting:

1. Aerospace Industry: The aerospace industry requires components with complex geometries and high precision. The lost foam casting process can cater to these requirements, offering potential for manufacturing intricate parts with high dimensional accuracy, superior surface finish, and strength.

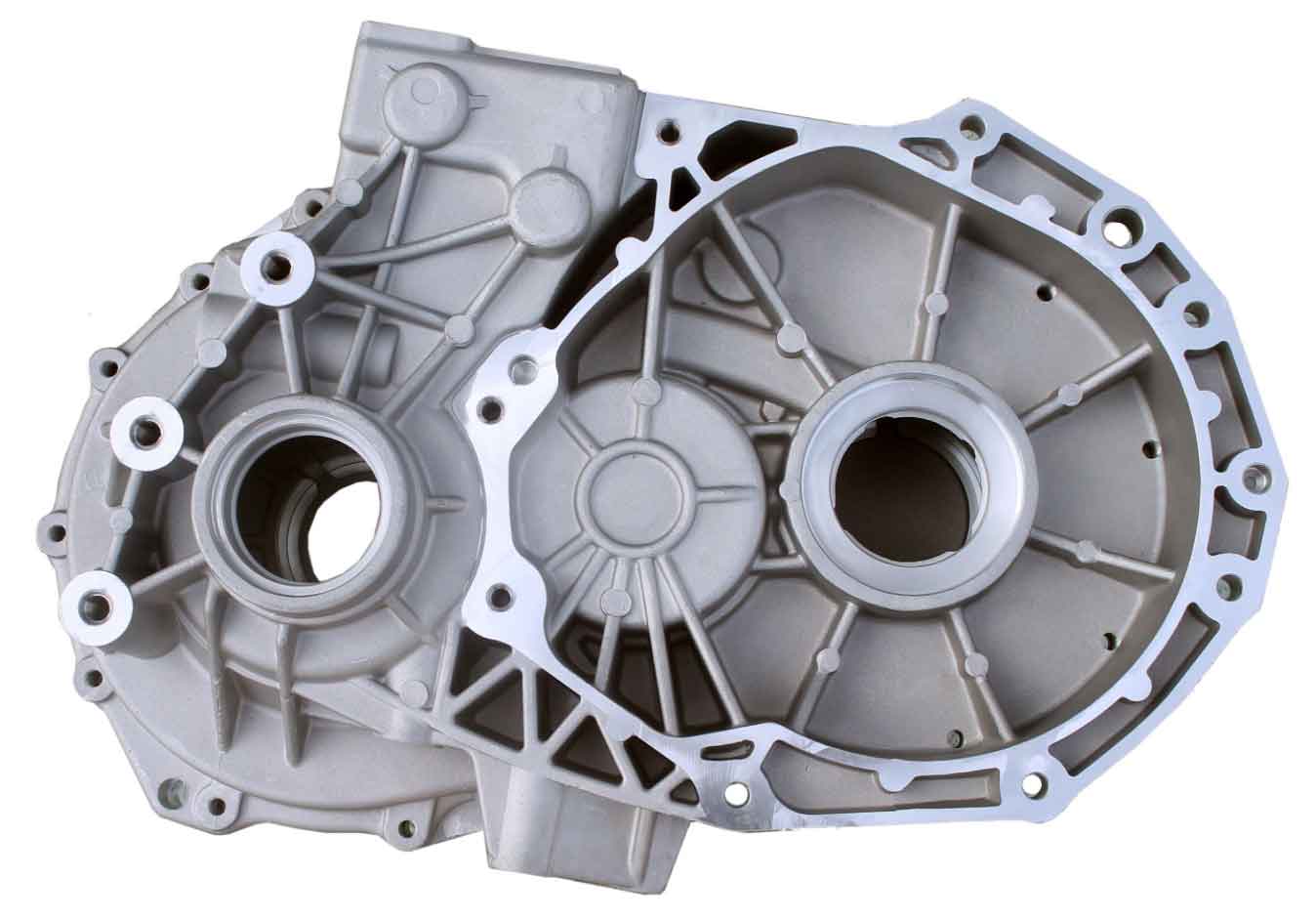

2. Automobile Industry: lost foam casting can be used to manufacture parts like engine blocks, cylinder heads, manifolds, and other components that require complex geometries. The ability to cast near-net-shape parts can reduce machining costs and increase production efficiency, which is critical in the high-volume automobile industry.

3. Energy Industry: In industries like wind energy and oil and gas, lost foam casting can be used to create large, complex parts with superior mechanical properties. This is particularly useful for components like turbine blades and intricate pipeline networks.

4. Medical Devices: The ability to produce complex shapes with high precision makes lost foam casting a potential choice for manufacturing medical devices, such as surgical tools and implantable devices.

5. Art and Sculpture: The fine detail that lost foam casting can achieve opens up possibilities in the world of art and sculpture, allowing artists to create intricate pieces that might not be possible with traditional casting methods.

6. Architectural Components: The architectural industry can leverage lost foam casting to create customized components and ornamental features. The high level of detail and smooth finish achievable with lost foam casting can be beneficial for both functional and aesthetic aspects.

7. Robotics: The potential to cast complex shapes with high precision can be very advantageous in the creation of parts for robots, drones, and other advanced technology devices.

While the possibilities are exciting, there are still challenges to be overcome, including managing the environmental impact of polystyrene foam and emissions control. Nonetheless, with ongoing research and development, lost foam casting could be a transformative technology in many sectors, offering new possibilities for the design and manufacture of a wide range of components.