Spheroidal graphite iron (SG iron), also known as ductile iron or nodular cast iron, has revolutionized various industries due to its unique combination of mechanical properties. In the automotive industry, the demand for materials that offer enhanced durability, strength, and reliability has driven significant advancements in spheroidal graphite iron. This article explores the latest developments in spheroidal graphite iron, focusing on its enhanced durability for automotive applications.

Introduction

The automotive industry continuously seeks materials that can withstand harsh operating conditions while providing high performance and longevity. Spheroidal graphite iron, with its excellent mechanical properties and cost-effectiveness, has emerged as a preferred choice for many automotive components. Recent advancements in the production and processing of spheroidal graphite iron have further enhanced its durability, making it even more suitable for demanding automotive applications.

Properties of Spheroidal Graphite Iron

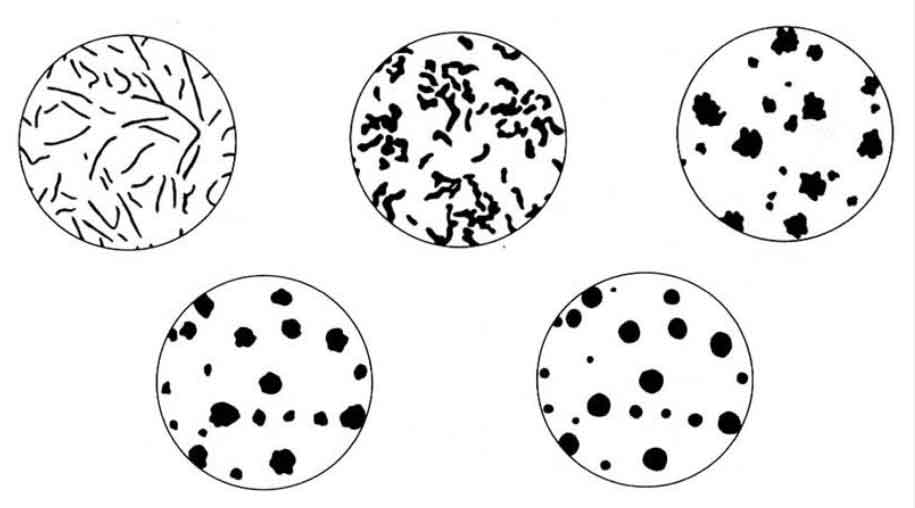

Spheroidal graphite iron is characterized by its spherical graphite nodules, which contribute to its superior mechanical properties compared to traditional gray cast iron. The key properties of spheroidal graphite iron include:

- High Tensile Strength: Allows components to withstand significant stress without breaking.

- Excellent Ductility: Provides flexibility, reducing the likelihood of cracking under impact.

- Good Fatigue Resistance: Enhances the lifespan of components subjected to cyclic loading.

- Superior Wear Resistance: Minimizes wear and tear in high-contact applications.

Table 1: Key Properties of Spheroidal Graphite Iron

| Property | Value |

|---|---|

| Tensile Strength | 600 – 900 MPa |

| Yield Strength | 350 – 600 MPa |

| Elongation | 10 – 18% |

| Hardness | 150 – 300 HB |

| Fatigue Strength | High (similar to steels) |

Advancements in Spheroidal Graphite Iron Production

1. Enhanced Alloying Techniques

Recent advancements in alloying techniques have significantly improved the properties of spheroidal graphite iron. The introduction of elements such as copper, nickel, and molybdenum has enhanced its strength, toughness, and wear resistance.

Benefits of Enhanced Alloying:

- Improved mechanical properties

- Increased resistance to wear and corrosion

- Enhanced performance under high-temperature conditions

Table 2: Impact of Alloying Elements on Spheroidal Graphite Iron

| Element | Effect on Properties |

|---|---|

| Copper | Increases strength and hardness |

| Nickel | Enhances toughness and corrosion resistance |

| Molybdenum | Improves high-temperature performance |

2. Advanced Heat Treatment Processes

Heat treatment processes such as austempering have been developed to optimize the microstructure of spheroidal graphite iron, resulting in superior mechanical properties. Austempered ductile iron (ADI) exhibits a combination of high strength and ductility, making it ideal for demanding automotive applications.

Benefits of Austempering:

- Enhanced strength and toughness

- Improved wear resistance

- Greater fatigue resistance

3. Innovative Casting Techniques

Innovative casting techniques, including computer-aided design (CAD) and simulation, have improved the accuracy and consistency of spheroidal graphite iron components. These techniques allow for precise control over the cooling rate and solidification process, resulting in uniform microstructures and reduced defects.

Benefits of Innovative Casting:

- Reduced casting defects

- Improved dimensional accuracy

- Enhanced mechanical properties

Applications of Spheroidal Graphite Iron in Automotive Industry

1. Engine Components

Spheroidal graphite iron is widely used in the manufacturing of engine components such as crankshafts, connecting rods, and cylinder heads. The material’s high strength and fatigue resistance make it suitable for withstanding the high stresses and cyclic loads encountered in engines.

2. Suspension Systems

The excellent ductility and toughness of spheroidal graphite iron make it ideal for suspension components such as control arms, stabilizer bars, and knuckles. These components require high impact resistance to ensure safety and durability.

3. Transmission Gears

Transmission gears made from spheroidal graphite iron benefit from the material’s superior wear resistance and fatigue strength. The advancements in heat treatment processes, such as austempering, have further enhanced the performance and lifespan of these gears.

Case Study: Spheroidal Graphite Iron Crankshafts

A study on the use of spheroidal graphite iron for crankshafts in high-performance engines revealed significant improvements in durability and performance. The crankshafts exhibited higher fatigue strength and wear resistance compared to traditional materials, resulting in extended service life and reduced maintenance costs.

Table 3: Comparative Performance of Spheroidal Graphite Iron and Traditional Materials in Crankshafts

| Material | Tensile Strength (MPa) | Fatigue Strength (MPa) | Wear Resistance |

|---|---|---|---|

| Spheroidal Graphite Iron | 750 | 400 | High |

| Gray Cast Iron | 250 | 150 | Moderate |

| Carbon Steel | 600 | 300 | High |

Future Trends in Spheroidal Graphite Iron Development

The future of spheroidal graphite iron in automotive applications looks promising, with ongoing research focused on further enhancing its properties and performance. Key areas of development include:

1. Nano-Enhanced Spheroidal Graphite Iron

Incorporating nanomaterials into spheroidal graphite iron has the potential to significantly enhance its mechanical properties, including strength, toughness, and wear resistance. This advancement could lead to even more durable and high-performance automotive components.

2. Eco-Friendly Production Methods

The development of eco-friendly production methods aims to reduce the environmental impact of spheroidal graphite iron manufacturing. Techniques such as recycling and the use of sustainable raw materials are being explored to achieve greener production processes.

3. Smart Manufacturing

The integration of smart manufacturing technologies, such as the Internet of Things (IoT) and artificial intelligence (AI), into spheroidal graphite iron production can optimize the casting and heat treatment processes. These technologies enable real-time monitoring and control, ensuring consistent quality and performance.

Conclusion

Advancements in spheroidal graphite iron have significantly enhanced its durability and performance, making it a material of choice for various automotive applications. Through innovative alloying techniques, advanced heat treatment processes, and cutting-edge casting methods, spheroidal graphite iron has achieved superior mechanical properties that meet the demanding requirements of the automotive industry. As research and development continue, spheroidal graphite iron is poised to play an even more critical role in the future of automotive manufacturing.