This article delves into the issues of scab and shrinkage cavity defects in the production of ductile iron gear reducer housings through lost foam casting. By optimizing the gating system and innovating the heat dissipation process, effective solutions to these defects are proposed. The transformation from top gating to bottom gating reduces molten iron turbulence during pouring, resolving the scab problem. The newly developed heat dissipation process addresses the shrinkage cavity issue in the hot spot area of the casting. Experimental results demonstrate that these improvements not only eliminate the defects but also enhance the overall quality and production efficiency of the casting.

1. Introduction

Lost foam casting is a modern casting technology that offers numerous advantages such as good surface quality, high dimensional accuracy, and high process yield. It has found wide application in the production of ductile iron components, including gear reducer housings. Gear reducer housings are crucial parts in mechanical equipment, demanding high strength, toughness, wear resistance, and shock resistance. The material commonly used for gear reducer housings is QT450 – 10.

However, during the production of gear reducer housings using the lost foam casting process, problems like scab on the surface and shrinkage cavities in certain areas frequently occur. These defects not only affect the appearance and dimensional accuracy of the castings but also undermine their mechanical properties and service life. Therefore, it is of great significance to conduct in – depth research on how to solve these problems to improve the quality of gear reducer housings.

2. Original Process of Ductile Iron Gear Reducer Housing

2.1 Process Parameters

The original process for the gear reducer housing is shown in Figure 1. The process allowance on the end face is designed to be 4 mm. The tapping temperature ranges from 1580 – 1600 °C, and the pouring temperature is between 1370 – 1440 °C. The pouring negative pressure is set at – 0.06 – 0.04 MPa, and the negative pressure holding time is 900 s. The chemical composition of the gear reducer housing is presented in Table 1.

| Figure 1: Gear Reducer Housing Combination Process |

|---|

| [Insert an image here showing the combination process of the gear reducer housing, with clear markings of different parts and process details] |

| Table 1: Chemical Composition of QT450 – 10 Gear Reducer Housing (Mass Fraction, %) | |||||||

|---|---|---|---|---|---|---|---|

| Main Elements | C | Si | Mn | P | S | Mg | RE |

| Content | 3.5 – 4.0 | 2.0 – 3.0 | 0.45 | 0.05 | ≤0.025 | 0.02 – 0.06 | 0.015 – 0.04 |

2.2 Defects in the Original Process

Although the mechanical properties of the Y – type sample meet the requirements of QT450 – 10, and the nodularity of 2 – 3 levels also conforms to the technical requirements of the ductile iron gear reducer housing, defects such as shrinkage porosity, shrinkage cavities, and scabs occur during the trial production of the gear reducer housing by lost foam casting. During small – batch production, scabs are found in a large proportion on the end face of the gear reducer housing, and shrinkage cavities appear at geometric hot spots.

| Defect | Appearance | Location |

|---|---|---|

| Scab | Pit – like, similar to orange peel | End face of the gear reducer housing |

| Shrinkage Cavity | Irregular – shaped holes with rough walls | Geometric hot spots |

3. Formation Reasons of Scab and Shrinkage Cavity in Gear Reducer Housing

3.1 Formation Reasons of Scab

3.1.1 General Reasons for Carbon – related Defects in Lost Foam Casting

Carbon – related defects are common in lost foam casting, and scab is one of the manifestations. The copolymer material used for the white mold of ductile iron balances the gas evolution and solid carbon content of EPS and EPMMA, reducing the risk of carbon – related defects and air hole defects in the casting. However, during the thermal decomposition of the copolymer foam pattern in lost foam casting, a large number of gaseous, liquid, and solid pyrolysis products are generated. The transfer of these products is affected by various factors, leading to diverse states, compositions, and discharge forms, which is the fundamental cause of scab defects.

3.1.2 Influence of Pouring System on Scab Formation

The original process of the gear reducer housing is nominally top – gating but is actually a mid – bottom gating process using the cavity as the runner. The casting is a solid of revolution, with an upper – end thickness of 35 mm and a rapid reduction in thickness from 50 mm to 13 mm at the bottom. The inner gate is designed on the top surface. During pouring, the high – temperature molten iron enters the top surface of the white mold from the inner gate. Instead of filling the mold gradually from top to bottom, it directly penetrates the thick – walled area at the top, uses the top of the cavity as the runner, and then fans out and fills downwards when it reaches the thin – walled area. After reaching the bottom, it fills upwards, resulting in a mid – bottom gating turbulent filling method. This causes “cold ends” in the thick and dead – end areas at the top and sides, forming scab defects.

3.2 Formation Reasons of Shrinkage Cavity

3.2.1 General Causes of Shrinkage Cavity in Ductile Iron Castings

The fundamental cause of shrinkage cavities in ductile iron castings is that during the liquid shrinkage and solidification of the alloy, a certain part of the casting (usually the hot spot that solidifies last) cannot be timely compensated with liquid metal, resulting in irregular – shaped holes with rough walls.

3.2.2 Specific Reasons for Shrinkage Cavity in Gear Reducer Housing

For the gear reducer housing, since the mechanical properties of the Y – type sample meet the requirements, and there are no problems such as cold shuts or sand adhesion on the surface, factors such as nodularization treatment temperature, pouring temperature, and negative pressure can be excluded as causes of shrinkage cavities. The shrinkage cavity defects of the gear reducer housing mainly exist in the thick – walled positions of the side – processed through – holes, which are mainly caused by geometric hot spots. To solve the shrinkage cavity problem of the gear reducer housing, it is necessary to start from casting process measures, change the casting cooling structure, increase the heat dissipation surface area, reduce the local modulus, and eliminate the geometric hot spots of the casting.

4. Solutions and Verification of Gear Reducer Housing Defects

4.1 Solutions to Gear Reducer Housing Scab

4.1.1 Re – design of the Pouring System

The scab of the gear reducer housing is mainly caused by the unreasonable design of the pouring system, which leads to a mid – bottom gating filling method and molten iron turbulence during pouring. The solution is to re – design the pouring system and change it to a bottom – gating system. In the new bottom – gating system, the filling method is pure bottom – gating. During the filling process, the high – temperature molten iron fills the mold steadily from the bottom up. As a result, the low – temperature molten iron at the front end and the incompletely gasified products of the white mold stay in the processing allowance area on the top surface of the cavity, obtaining a sound – surfaced casting.

| Figure 2: Pouring System |

|---|

| [Insert an image here showing the new pouring system, clearly depicting the flow path of molten iron from the bottom to the top of the mold] |

4.1.2 Theoretical Calculation of the Pouring System

The casting time is calculated as follows: \(t = 24s\) The calculation formula for the average static pressure head height of bottom – injection (\(P = C\)) is: \(H_{p}=H_{0}=34cm\) The formula for calculating the minimum cross – sectional area of the inner gate is: \(A_{g}=\frac{G}{0.31 t v \sqrt{H_{p}}}=3.46cm^{2}\) Based on production experience, for lost foam casting, the minimum cross – section of the inner gate is generally slightly larger than that of sand casting. Considering the casting structure, the newly designed inner gate is a central casting, with four inner gates. The cross – section size of each inner gate is \((7 + 1×40)mm\), and the cross – sectional area of the inner gate is \((11.2 – 12.8)cm^{2}\). With a pressure head of 200 mm, the length of the sprue is designed to be 480 mm.

| Table 2: Comparison of Pouring System Parameters Before and After Optimization | | —- | —- | —- | | Pouring System Parameter | Original Process | Optimized Process | | Pouring Method | Mid – bottom gating (using cavity as runner) | Bottom gating | | Inner Gate Cross – Sectional Area Calculation Method | – | \(A_{g}=\frac{G}{0.31 t v \sqrt{H_{p}}}\), and adjusted according to experience | | Inner Gate Cross – Sectional Area | – | \((11.2 – 12.8)cm^{2}\) | | Sprue Length | – | 480 mm |

4.1.3 Verification of the Solution

After conducting tests according to the new casting process and mass – producing 2000 pieces for verification, the surface quality of the castings produced by the new casting process is qualified, and no batch – scale surface scab defects occur again. As shown in Figure 3, before the process optimization, there are scab defects on the casting surface (Figure 3a), while after the optimization, the casting surface is qualified (Figure 3b).

| Figure 3: Casting Surface Quality Before and After Process Optimization |

|---|

| [Insert an image here with two sub – images, one showing the scab – covered casting surface before optimization (Figure 3a) and the other showing the smooth and defect – free casting surface after optimization (Figure 3b)] |

4.2 Solutions to Gear Reducer Housing Shrinkage Cavity Defects

4.2.1 Limitations of Traditional Methods

For casting shrinkage cavity defects, the traditional solutions are to set risers at hot spots to compensate for the metal liquid required due to volume changes during casting formation and to use a chilling system, usually using chills to create an artificial end zone at the hot spot, forming a sequential solidification to eliminate shrinkage cavity defects. However, for the lost foam casting of gear reducer housings, these two methods are not applicable. Setting risers reduces the process yield of the gear reducer housing casting and increases the overall process difficulty. Using chills in the lost foam casting process is prone to chill detachment during molding, which may cause casting deformation, increasing the process difficulty and affecting the quality stability of the gear reducer housing, while also increasing the casting cost.

4.2.2 New Heat Dissipation Process

A new lost foam casting process, the heat dissipation process, has been developed to address the shrinkage cavity problem in the hot spots of ductile iron. The core of this process is to change the casting structure, increase the heat dissipation surface area, reduce the modulus at the hot spots of the casting, and enable the negative – pressure gas to take away a large amount of heat during the solidification stage, achieving a chilling effect.

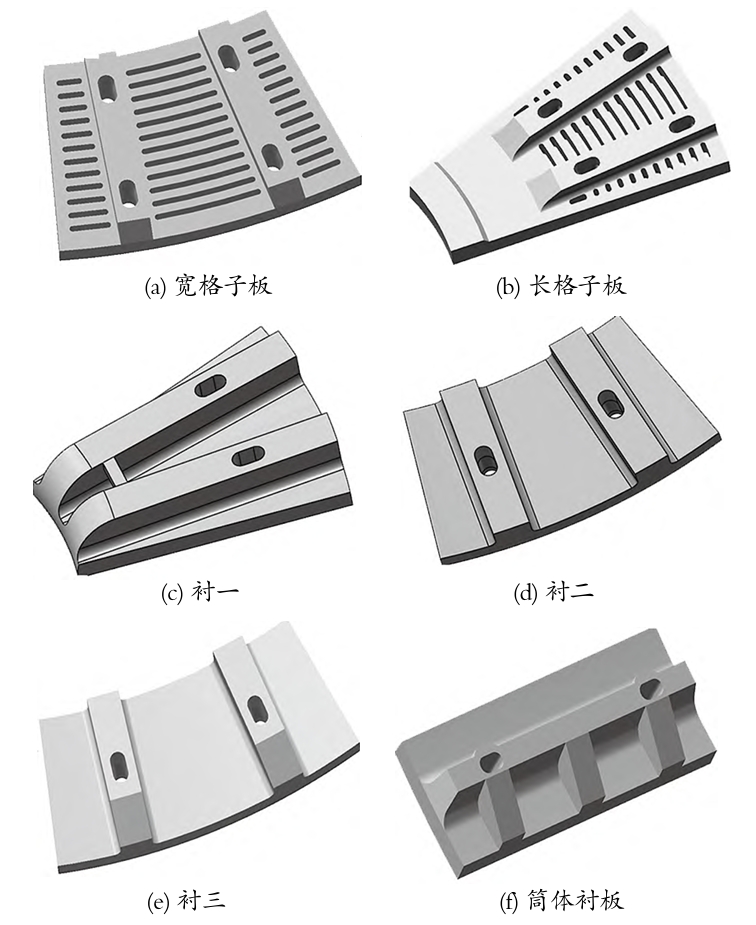

The specific method is to bond foam sheets (hereinafter referred to as heat dissipation sheets) at the hot spots of the casting, as shown in Figure 4. After that, the casting is processed through coating, drying, boxing, molding, pouring, and other processes to obtain qualified castings. During the pouring and solidification of the lost foam casting process, negative pressure is continuously applied. When the negative – pressure pump is working, cold air enters the sand box from the upper surface, exchanges heat with the casting and the heat dissipation sheets, and takes away heat. The large specific surface area of the heat dissipation sheets reduces the local modulus of the casting. The cold air takes away a large amount of heat, and a micro – channel flow heat transfer is formed between the local molding sand in contact with the casting and the heat dissipation sheets, creating a chilling zone with a large temperature difference. The heat dissipation sheets play the role of chills, changing the local solidification mode of the casting to a similar sequential solidification, thus eliminating shrinkage cavity and shrinkage porosity defects. The principle diagram is shown in Figure 5.

| Figure 4: Schematic Diagram of the Heat Dissipation Sheet Process |

|---|

| [Insert an image here showing the gear reducer housing with heat dissipation sheets bonded at hot spots, clearly marking the positions of the heat dissipation sheets, casting, inner gate, and sprue] |

| Figure 5: Schematic Diagram of the Heat Dissipation Sheet Process Principle |

|---|

| [Insert an image here showing the heat transfer process during the heat dissipation sheet process, with arrows indicating the flow direction of cold air and heat transfer paths] |

4.2.3 Verification of the Heat Dissipation Process

The original process – produced gear reducer housing castings had shrinkage cavity defects in the bolt through – holes, as shown in Figure 6. By analyzing the casting structure, it was found that the shrinkage cavity position of the gear reducer housing belonged to a geometric hot spot with a high shrinkage cavity tendency, which was consistent with the shrinkage cavity defects in batch production. After comprehensively considering various factors, the heat dissipation process was adopted. In the blanking and bonding process, 12 heat dissipation sheets with dimensions of \((50×30×7)mm\) were bonded in the hot – spot area of the casting, and the other process steps remained unchanged. After trial production and machining verification, the bolt through – holes of the gear reducer housing were normal without quality problems, as shown in Figure 8. During mass production using the heat dissipation process, 2000 gear reducer housings were continuously produced, and no batch – scale shrinkage cavity defects appeared in the bolt through – holes after processing.

| Figure 6: Casting Shrinkage Cavity |

|---|

| [Insert an image here showing the shrinkage cavity in the bolt through – hole of the gear reducer housing casting] |

| Figure 7: Improved Housing Combination Process |

|---|

| [Insert an image here showing the improved housing combination process with the heat dissipation sheets integrated, clearly presenting the overall structure and process flow] |

| Figure 8: Qualified Casting |

|---|

| [Insert an image here showing the final qualified gear reducer housing casting with no visible defects] |

5. Conclusion

5.1 Resolution of Scab Defects

By optimizing the gating system process, the filling during pouring becomes stable. The process allowance is utilized to collect the front – end molten iron with impurities, effectively solving the scab defect of the casting. The change from the original mid – bottom gating to the bottom – gating system ensures a smooth filling process, preventing the formation of “cold ends” and thus avoiding scab formation.

5.2 Resolution of Shrinkage Cavity Defects

For the shrinkage cavity problem caused by hot spots in the lost foam casting of ductile iron parts, the traditional riser and chill methods have significant drawbacks in terms of process difficulty. The newly designed heat dissipation sheet process is a novel and effective solution. By setting a certain number of heat dissipation sheets at the hot spots of the casting, the local heat dissipation speed is enhanced, eliminating the geometric hot spots of the casting and thus solving the shrinkage cavity defect. The heat dissipation sheet process has been verified through the production of gear reducer housing castings, demonstrating that it meets the design requirements and can effectively solve the shrinkage cavity problem in lost foam casting.

In conclusion, the optimization of the lost foam casting process for ductile iron gear reducer housings not only improves the quality of the castings but also provides valuable experience and reference for the production of other similar castings. Further research can be carried out to continuously optimize these processes and explore more efficient and reliable casting methods.