In recent years, the rapid development of the automotive industry has intensified competition, leading to significant price reductions in vehicles. As a result, component suppliers must reduce manufacturing costs to meet market demands. For ductile iron casting production, optimizing processes to improve yield is an effective cost-saving method. Traditionally, single-layer layouts are used in ductile iron casting due to complex geometries and the need for effective feeding systems. However, single-layer approaches often suffer from low yield and high costs. In this competitive environment, advancing process technologies to lower production costs and enhance yield is essential for business growth. This study explores a double-layer process for a ductile iron component, leveraging structural characteristics and simulation analysis to achieve higher yield and efficiency.

Ductile iron, also known as ductile cast iron, is widely used in automotive applications for its excellent mechanical properties, including high strength, ductility, and wear resistance. However, the production of ductile iron castings faces challenges such as shrinkage defects and low yield when using conventional single-layer methods. The double-layer process proposed here addresses these issues by stacking two castings with a sand core in between, thereby increasing mold cavity density and improving yield. This approach not only reduces costs but also enhances productivity, making it a viable solution for modern foundries.

The production environment for this study involved a horizontal molding line (ACE-5) with a mold size of 900 mm × 800 mm × 250 mm/230 mm (upper/lower) and an automatic pouring system. The component under investigation is a bracket-type ductile iron casting with the following specifications: material grade QT450-10, dimensions 243 mm × 118 mm × 50 mm, weight 2.3 kg, tensile strength ≥450 MPa, yield strength ≥310 MPa, hardness 160-210 HBW, nodularity ≥80%, and elongation ≥10%. Internal defects were required to meet ASTM-E446 Level 2 or better. Initial analysis using Magma simulation software revealed dispersed hot spots and shrinkage risks, necessitating at least two feeders per casting in a single-layer layout. This initial design had a yield of only 22%, with additional issues like weak sand mold integrity leading to defects such as sand inclusions and fins.

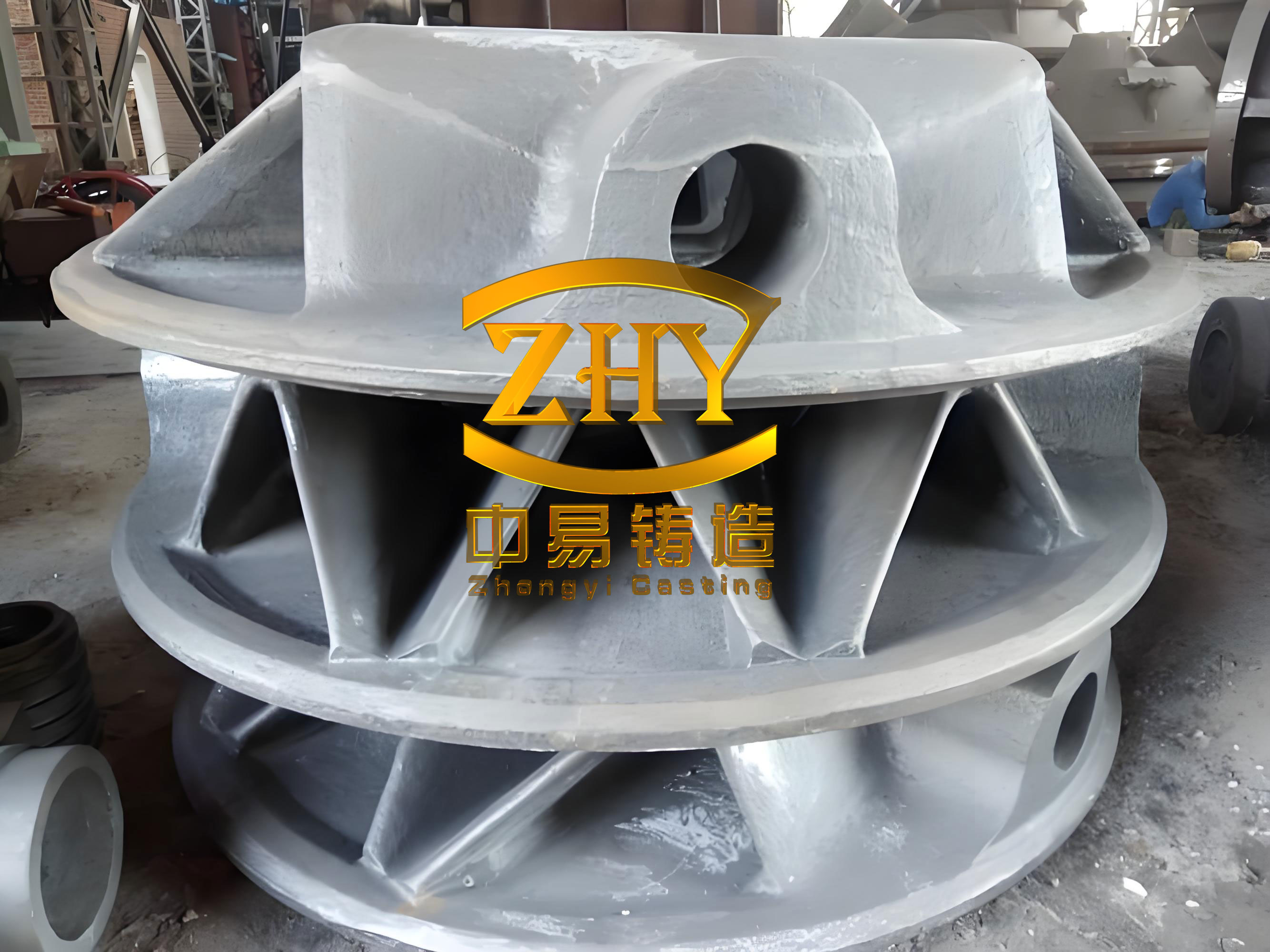

To overcome these limitations, a double-layer process was designed. The casting has a flat structure with one simple side and one complex side. By stacking two castings with their complex sides facing each other and separated by a sand core (weight 2.5 kg), the mold can accommodate 16 cavities per mold. This configuration addresses the sand mold strength issue by using the core to form the complex geometries, while doubling the output. The yield for this double-layer ductile iron casting setup is calculated as follows:

$$ \text{Yield} = \frac{\text{Total Casting Weight}}{\text{Total Mold Weight}} \times 100\% = \frac{2.3 \times 16}{100} \times 100\% = 36.8\% $$

Compared to the single-layer yield of 22%, this represents a 14.8% improvement, along with doubled production efficiency. The feasibility of this double-layer ductile iron casting process was validated through mold flow analysis, examining parameters like filling temperature, velocity, pressure, and solidification.

The mold flow analysis for the double-layer ductile iron casting included several key aspects. Filling velocity and temperature distributions were monitored to ensure uniform flow and avoid cold shuts or turbulence. The temperature and maximum pressure contrast were analyzed to identify potential gas entrapment or mold erosion. Solidification behavior was assessed using liquid fraction and shrinkage prediction models. The results indicated that the filling process was stable, with temperatures maintained within an optimal range of 1350°C to 1400°C. The solidification analysis showed no significant shrinkage porosity risks, confirming that the feeding system with two feeders per casting pair was effective. The following table summarizes the critical parameters from the simulation:

| Parameter | Value | Standard |

|---|---|---|

| Filling Temperature Range | 1350-1400°C | >1300°C |

| Maximum Pressure | 0.15 MPa | <0.2 MPa |

| Solidification Time | 180 s | N/A |

| Shrinkage Risk | None | No Defects |

Additionally, the thermal behavior during solidification can be described by the Chvorinov’s rule for solidification time, which is crucial for avoiding shrinkage in ductile iron castings:

$$ t = B \left( \frac{V}{A} \right)^n $$

where \( t \) is the solidification time, \( V \) is the volume, \( A \) is the surface area, \( B \) is a mold constant, and \( n \) is an exponent (typically around 2 for sand molds). For the double-layer setup, the modified geometry resulted in a higher \( V/A \) ratio, promoting directional solidification and reducing shrinkage risks. The simulation confirmed that the liquid fraction dropped uniformly, with no isolated hot spots.

Production trials were conducted to validate the double-layer process for ductile iron castings. Mechanical properties were tested over 10 batches, and internal defects were examined using X-ray imaging. The results met all specifications, as shown in the table below:

| Property | Standard | Average Measured Value | Judgment |

|---|---|---|---|

| Tensile Strength (MPa) | ≥450 | 527 | OK |

| Yield Strength (MPa) | ≥310 | 334 | OK |

| Hardness (HBW) | 160-210 | 171 | OK |

| Nodularity (%) | ≥80 | 94 | OK |

| Elongation (%) | ≥10 | 14 | OK |

X-ray inspection revealed no shrinkage porosity or internal defects, with all samples complying with ASTM-E446 Level 2. This confirms the effectiveness of the double-layer process in producing high-quality ductile iron castings. The improvement in yield and reduction in defects can be attributed to the optimized feeding and solidification control. The economic impact is significant, as the cost per casting decreases due to higher material utilization and productivity. For instance, the cost savings can be estimated using the formula:

$$ \text{Cost Reduction} = \left(1 – \frac{\text{Yield}_{\text{single}}}{\text{Yield}_{\text{double}}}\right) \times 100\% = \left(1 – \frac{22}{36.8}\right) \times 100\% \approx 40.2\% $$

This demonstrates the substantial benefits of adopting double-layer processes for ductile iron components.

In conclusion, the double-layer process for ductile iron castings offers a viable solution to enhance yield and reduce production costs. By utilizing a sand core to separate stacked castings, foundries can address geometric complexities and improve mold cavity density. Mold flow analysis plays a critical role in validating the design, ensuring proper filling and solidification. Production results confirm that mechanical properties and internal quality meet stringent standards. This approach is particularly beneficial for flat-shaped ductile iron components, providing a competitive edge in the automotive industry. Future work could explore applications to other ductile cast iron parts and further optimization through advanced simulation techniques.

The success of this double-layer ductile iron casting process highlights the importance of innovation in foundry practices. As demand for cost-effective and high-performance components grows, such methodologies will become increasingly essential. By continuously refining processes like this, manufacturers can achieve sustainable growth in a competitive market. The integration of simulation and practical design ensures that ductile iron castings meet both quality and economic objectives, paving the way for broader adoption of double-layer techniques in the industry.