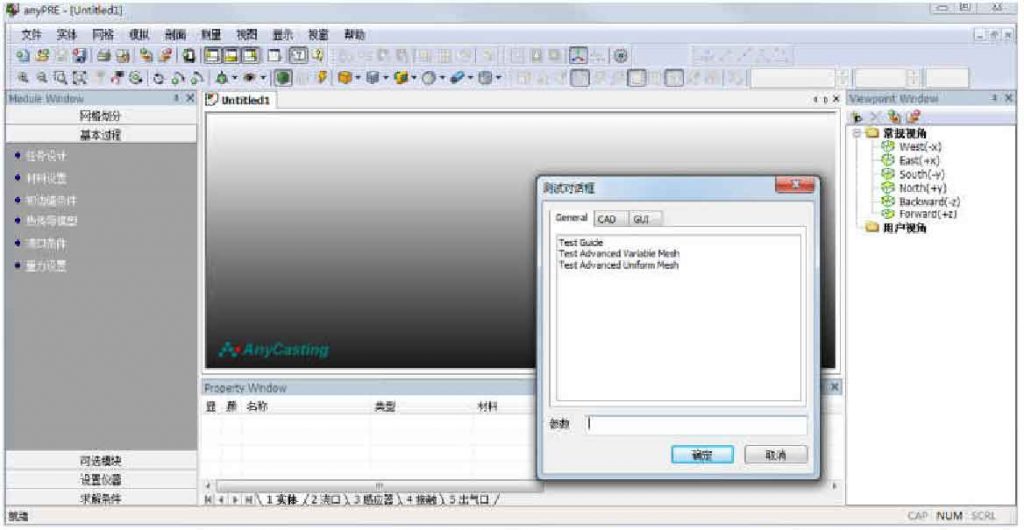

The process of numerical simulation of AnyCasting software includes: firstly, the pre-processing is carried out by any pre, including the selection of physical model, the establishment and import of casting model, the setting of material and mold parameters, meshing, the setting of boundary and heat exchange conditions, the setting of solving conditions and operating parameters, etc.; secondly, the calculation is carried out by any solver; and the post-processing is carried out by any post The module reads the calculation results, and displays various defects and filling solidification process through various gradient distribution diagrams and curves, so as to adjust the model and optimize the process parameters. The main interface of AnyCasting software is shown in Figure 1.

(1) Establishment and import of 3D model

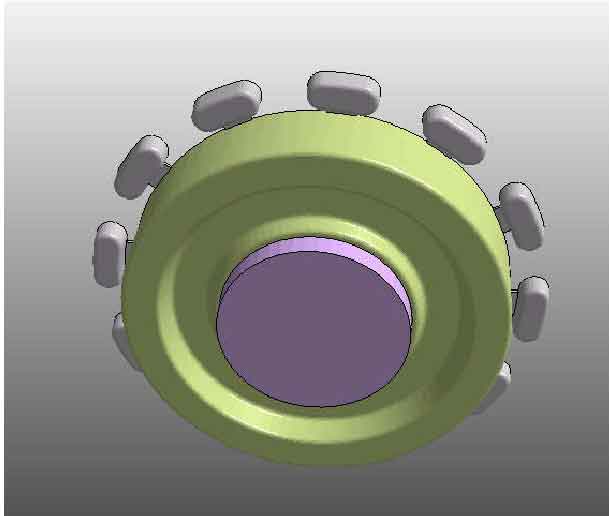

The three-dimensional model of wheel shaped squeeze casting parts is drawn by using Pro / E software, as shown in Figure 2. The model is composed of overflow trough, gate with diameter of 80mm at the bottom and squeeze casting parts. The numerical model is output to standard STL format, read by AnyCasting software, and imported to check the integrity of the model.

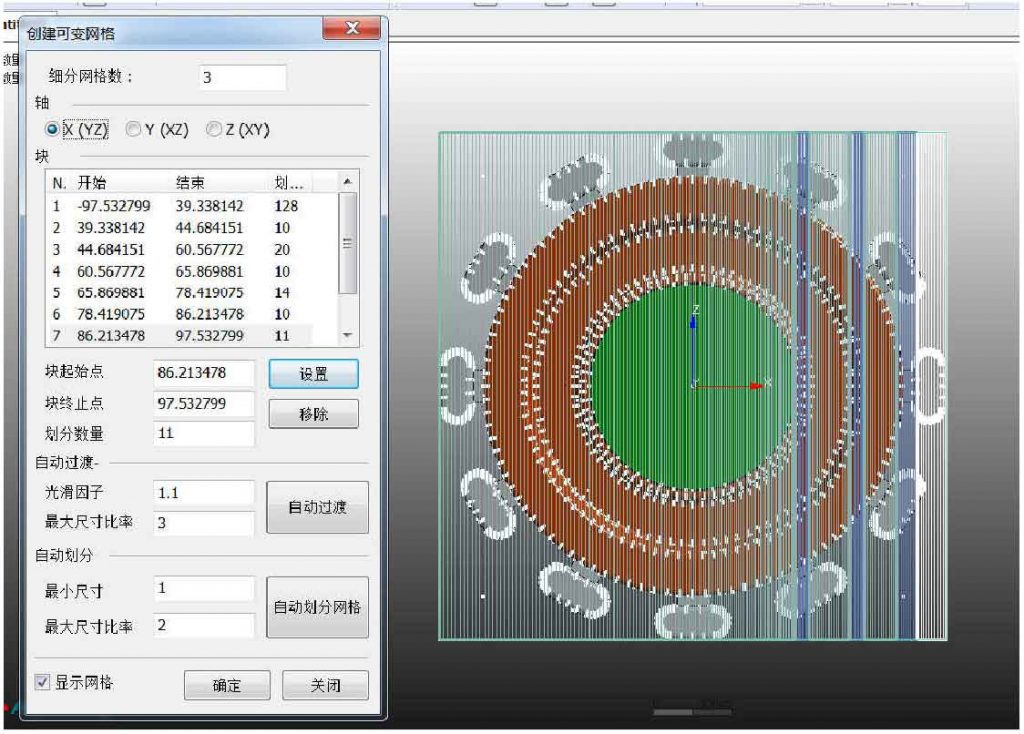

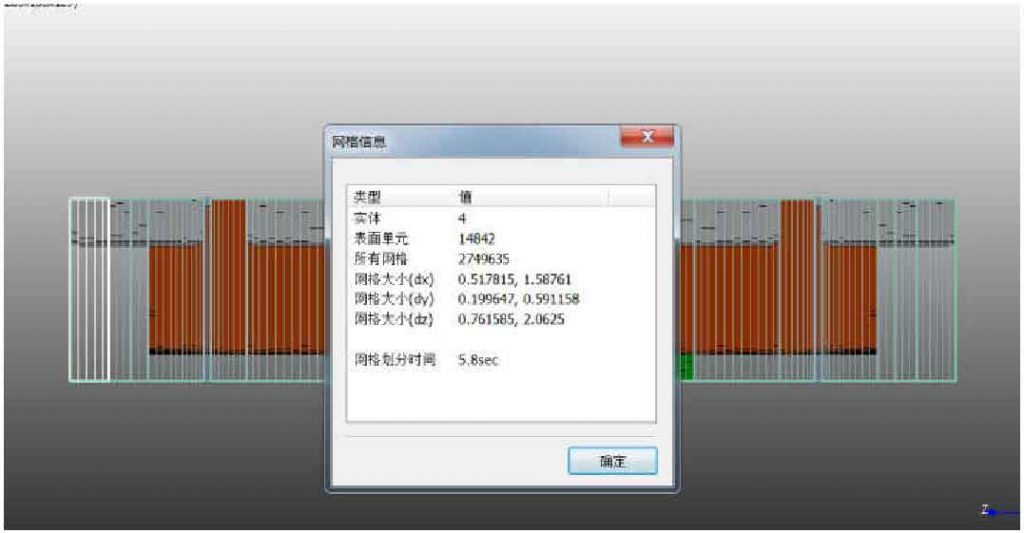

(2) Meshing

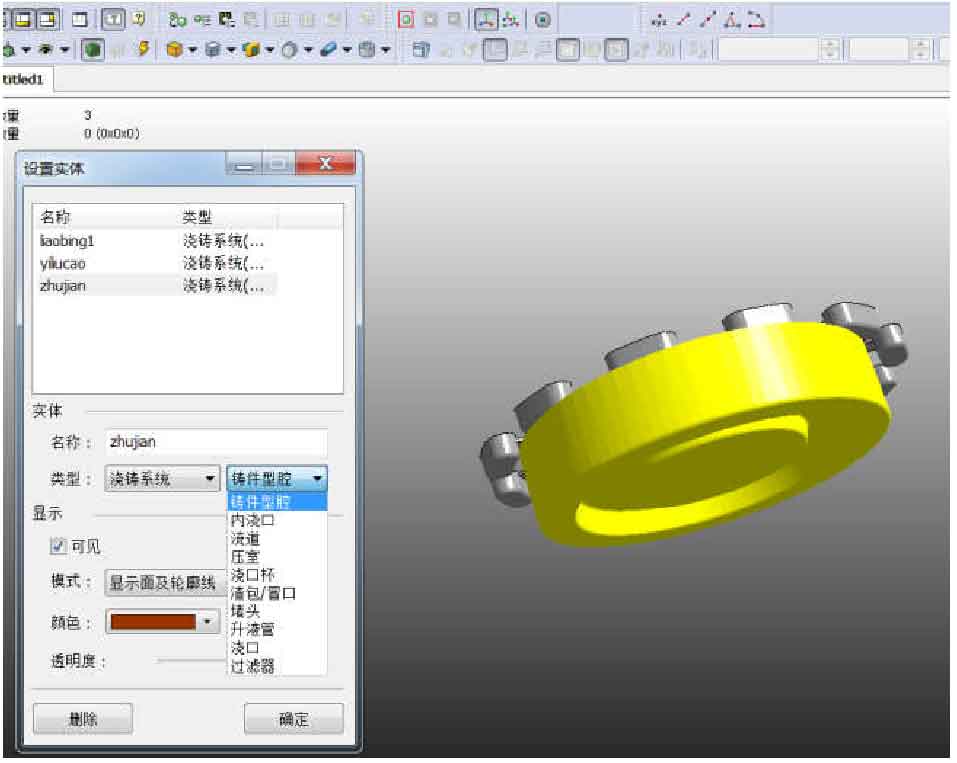

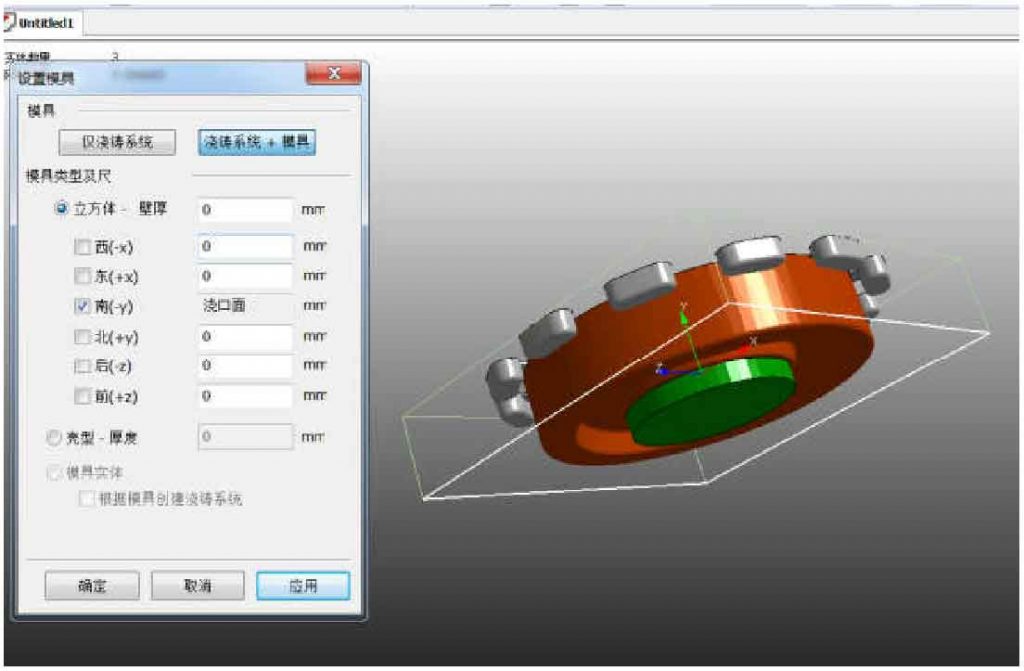

Anypre, the preprocessing module of AnyCasting software, reads the 3D model of squeeze casting parts, and sets the properties of squeeze casting parts, including runner, overflow groove and cavity, as shown in Figure 3. The mold system also needs to be simulated properly, as shown in Figure 4. After setting the gating system and mold, the 3D model system is meshed by software. In this paper, the non-uniform variable meshing method is adopted. The specific meshing process is shown in Figure 5. The total number of meshing units of the whole squeeze casting part model is 2749635, as shown in Figure 6.

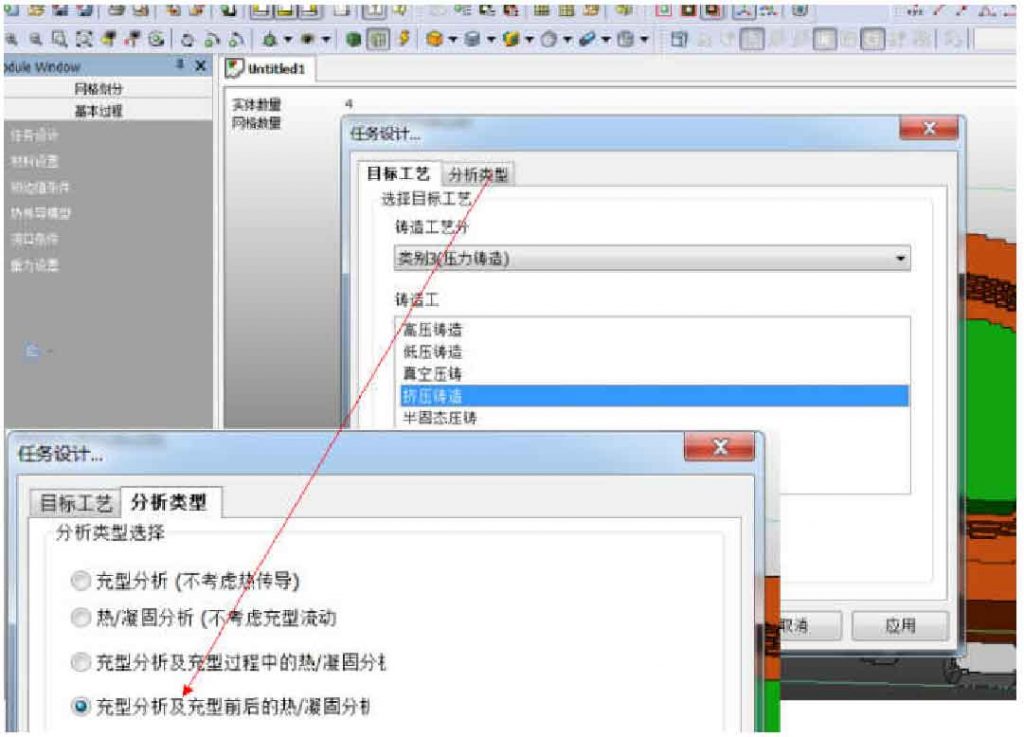

(3) Simulation process settings

After the model mesh is divided, various conditions need to be set. As shown in Figure 7, the simulation process must first select the target process, the experiment is rheo squeeze casting process, the set type is squeeze casting under pressure casting, the analysis type is mold filling analysis and thermal / solidification analysis before and after mold filling.

Some parameters of 7075 aluminum alloy for squeeze casting parts are not available in the original database of the software, so it is necessary to manually input various thermophysical parameters for setting. Check the material manual, such as thermal conductivity λ is 175W / (m · K), specific heat CP is 862j / (kg · K), density ρ is 2.81g/cm3, solid phase temperature is 635 ℃, liquid phase temperature is 477 ℃, etc. The hot work die steel H13 in the database of die material selection contains abundant data of this material. The mold temperature is set in the initial boundary value module, and various heat conduction coefficients and gravity acceleration are set in the heat conduction model module.

In the simulation process, the heat transfer coefficient should be set. The heat transfer coefficient between the mold and the casting is 1000W / (M2 · K), the heat transfer coefficient between the air and the casting and between the air and the mold is 41.87w / (M2 · K), the heat transfer coefficient between the moving mold and the fixed mold is 2000W / (M2 · K), and the gravity acceleration is 980cm / S2.

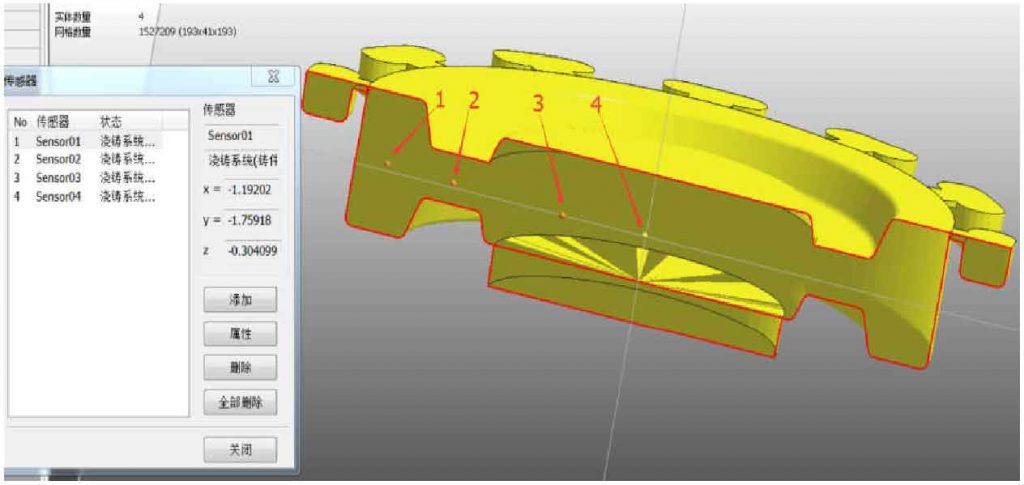

The pouring temperature, injection speed and gate area are set in the gate condition module. Setting the gate surface of the model, the thermal condition corresponds to the pouring temperature, and the filling condition can choose either the injection speed or the extrusion pressure. We can also select the relevant optional modules according to the needs, such as semi-solid module, particle tracking and so on. In the simulation experiment, the semi-solid module and particle tracking are selected, the instrument is set, and the temperature sensor is added to check the change of temperature field. In the simulation experiment, the instrument module is set, and the data sensors of 1, 2, 3 and 4 positions are set, as shown in Figure 8. After saving the set conditions, anyslow performs the calculation, and then anypost demonstrates the analysis results.