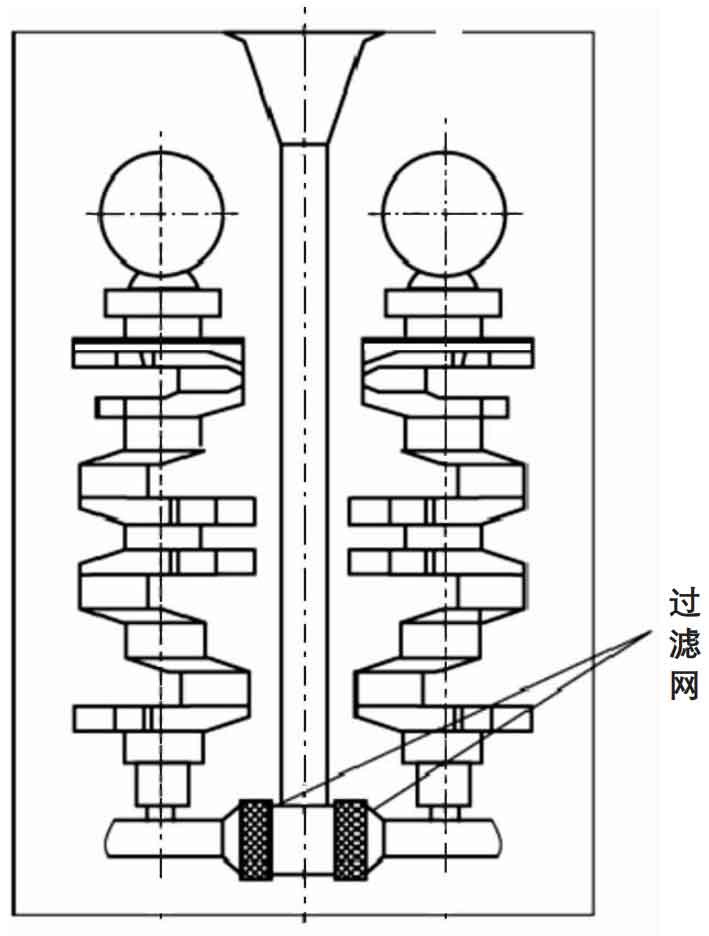

The wet sand mold casting process of nodular iron crankshaft is mainly divided into two parts: sand mold preparation and pouring. For the sand ratio required by the wet sand mold of crankshaft, it can be composed of new sand with mass fraction of 5% and old sand with reasonable proportion. The wet sand mold casting of nodular iron crankshaft adopts the process scheme of sequential solidification, as shown in Figure 1, which is suitable for mass production of crankshaft, It can also reasonably control the defects of castings and improve the qualified rate of cast crankshaft by controlling the relevant processes in the process link.

The defect analysis of nodular iron crankshaft in the actual production process can be divided into many defects, such as insufficient pouring, shrinkage cavity, porosity, inclusion and so on. For the reduction and control of these defects, the specific links in the casting process can be adjusted, so as to reduce or even overcome the casting defects.

1. Sand inclusion and other defects and their control

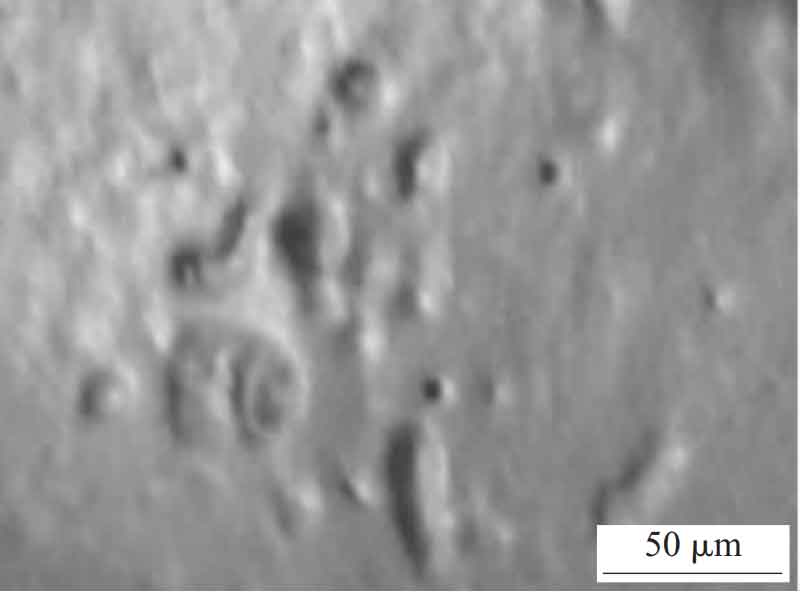

During the wet sand casting process of nodular iron crankshaft, impurities are sandwiched on the surface or inside of the casting due to the influence of many factors such as nodularizing agent and sand. As shown in Figure 2, the surface of the casting shows obvious sand hole defects due to sand inclusion. Once such defects occur, the subsequent cleaning and compensation of the crankshaft are increased, making the production process more complicated, In order to better reduce impurities in nodular iron crankshaft, control can be realized from two aspects:

(1) Add a filter screen at the end of pouring, as shown in Figure 1, to reduce impurities caused by one pouring.

(2) The secondary pouring controls the quality of the sand mold, strictly controls the water content of the sand, keeps the sand temperature the same, ensures that the sand mold of each part of the mold cavity has a certain compactness, and reduces the occurrence of sand inclusion defects in the secondary pouring.

2. Defects such as pores and their control

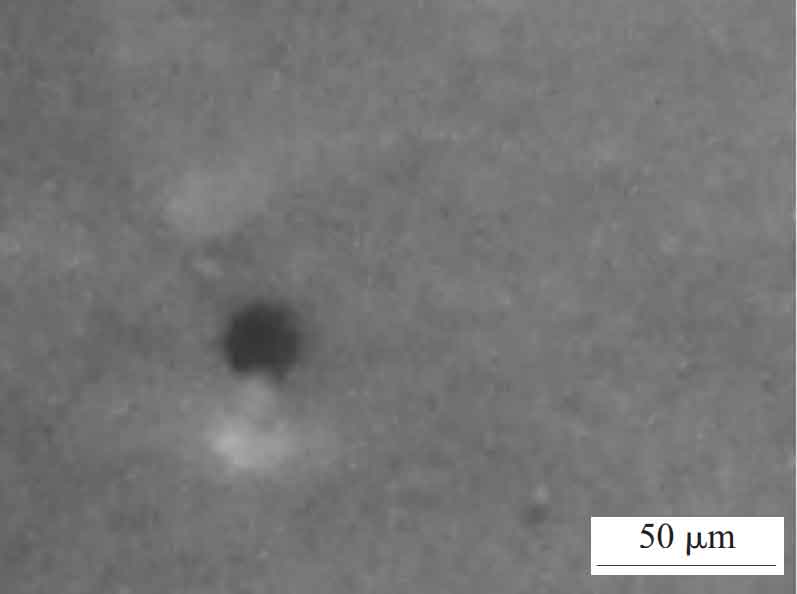

The blowhole defect of nodular iron crankshaft casting is mainly due to the hole formed in the casting by the nitrogen bubble trapped in the metal during solidification. As shown in Fig. 3, the blowhole defect reduces the effective impact resistance area of the crankshaft, causes relative stress concentration, and reduces the mechanical strength and fatigue resistance of the crankshaft. Therefore, for blowholes and other defects, on the one hand, the introduction of air source should be reduced, That is, raw iron with low nitrogen content is selected. On the other hand, exhaust holes are added at the position of casting wall thickness in the casting process, so as to reduce the precipitation pore defects of nodular iron crankshaft.

3. Defects such as shrinkage cavity and porosity and their control

After the molten metal enters the wet sand mold, the direction and strength of heat flow in the sand mold will induce shrinkage and shrinkage defects of the nodular iron crankshaft, as shown in Fig. 4. In the casting production, the shrinkage porosity and shrinkage cavity defects of nodular iron crankshaft are mainly caused by the hot joint. The defects can be controlled by placing cold iron outside the hot joint for feeding and so on. In general, the following control principles are adopted for the casting defects of various ductile iron crankshafts:

(1) Properly improve the rigidity of the mold. For the larger nodular iron crankshaft, the mold with high rigidity can be used. In addition, it is also necessary to appropriately reduce the concession of the mold, so that the liquid metal can flow evenly through the reaction of graphite expansion force, so as to effectively feed the casting.

(2) The carbon equivalent is 4.2% ~ 4.6%, the mass fraction of carbon is 3.6% ~ 3.9%, and the mass fraction of silicon is 1.8% ~ 2.2%.

(3) The spheroidizing treatment of nodular iron adopts rare earth magnesium alloy spheroidizing agent to reduce the residual amount of Mg.

(4) Reasonably select riser, cold iron and gating system. Cause sequential solidification and feed with riser.