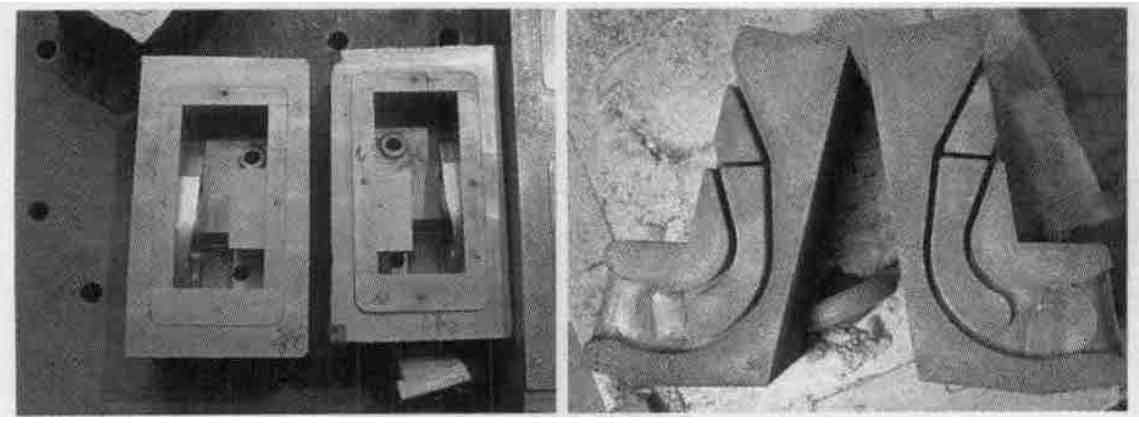

The wall thickness of the hatch sand casting is 2 mm, and the dimensional accuracy requirements are high. It is very difficult to control the size of the sand casting. The traditional wood mold and molding method can not meet the dimensional accuracy requirements of the sand casting. Therefore, the corresponding digital model diagrams of the outer shape and inner core are redesigned. On this basis, the metal mold outer skin and inner core molds are numerically processed. In the process of forming, the positioning pin and positioning sleeve are used to ensure the assembly accuracy in the process of forming, that is:

The positioning sleeve is embedded in the corresponding positioning position of the punched outer shape and inner core. In the process of forming, the positioning pin is used to assemble the inner core to the corresponding outer shape to ensure accurate positioning. This method ensures the dimensional accuracy of the formation in the sand mold. The figure shows the metal mold of aircraft hatch designed and manufactured by the project team. Using this method of molding, core making and molding, the size range of the developed hatch sand mold casting is within the specified range after being tested by the coordinate measuring instrument.