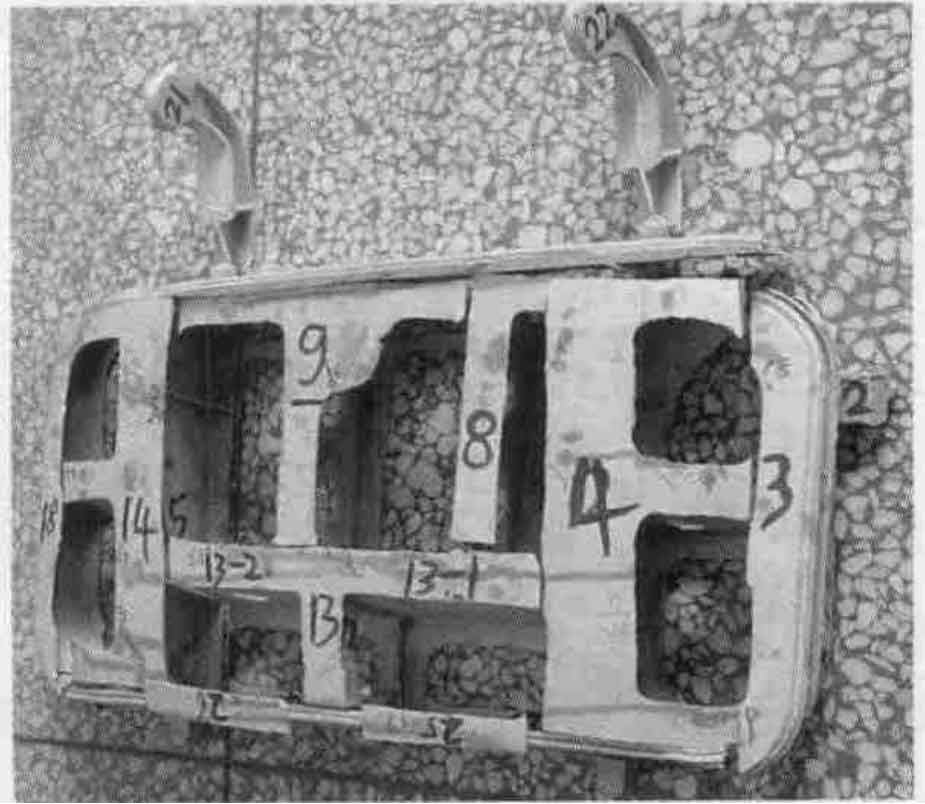

According to the above anti gravity test results, the differential pressure sand casting process was selected to pour the actual sand casting of Boeing cabin door. In order to master the internal quality of the sand casting, the overall anatomical flaw detection was carried out on the sand casting (Fig. 1).

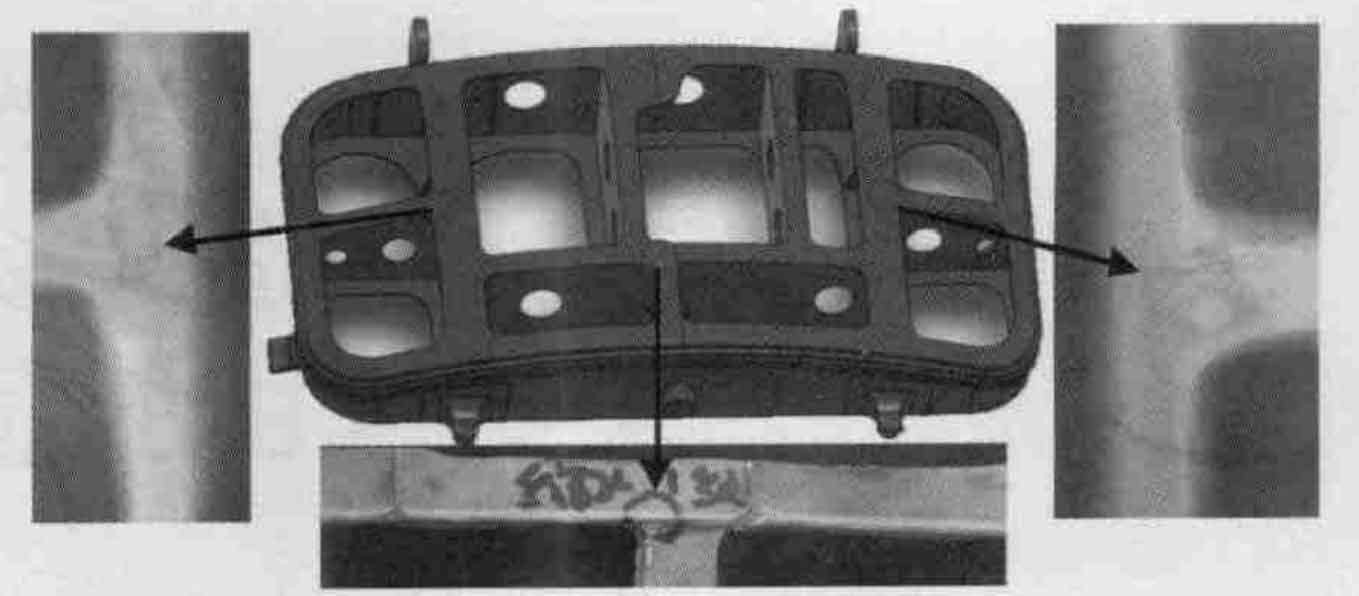

Figure 2 shows the results of radiographic inspection of sand castings after overall anatomy. It is found that shrinkage and porosity defects are generated at the intersection of ribs and strips and the center of laths. The reasons are analyzed: ① the intersection of reinforcement and strip is a hot joint, which is easy to overheat; ② The cooling speed of the central part of the strip relative to both ends is slow, and the solidification speed is slower than the two edge parts of the sand casting, which is equivalent to feeding the two edge parts. When it solidifies, it can not be fed, forming shrinkage cavity or porosity.

In view of the above problems, the sand casting process scheme of hatch casting is improved. The riser and chill are used at the center of the strip to ensure the feeding of the riser, and the chill plays the role of chilling and refining the structure. Through production verification, the defects of shrinkage cavity and porosity are solved, and the product quality is good.