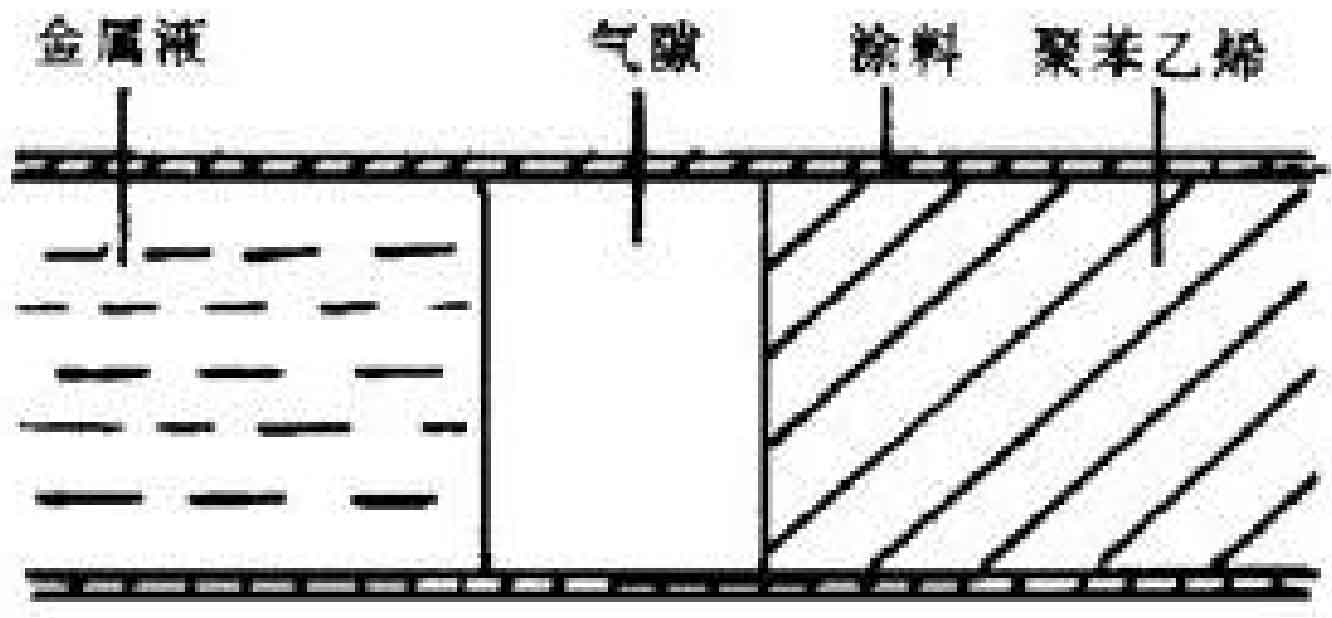

The main difference between lost foam casting and other castings is that the pattern remains in the mold. When the molten metal is poured into the mold, the pattern softens, melts, gasifies and burns under the action of high temperature, resulting in a series of liquid-gas-solid physical and chemical reactions. It is because of the existence of foam pattern that the molten metal has complex physical and chemical reactions and heat and mass transfer phenomena during filling process, as shown in the figure.

(1) In the air gap layer at the front of liquid metal flow, there are heat transfer between high-temperature liquid metal and coating, molding sand and pattern, such as conduction, convection and radiation;

(2) the physical and chemical reactions between the pyrolysis products of the foam pattern and molten metal, the coating and the molding sand, and the mass transfer.

(3) There is a certain pressure in the air gap formed between the pattern and the molten metal. With the increase of pressure and the endothermic reaction of pattern pyrolysis, the temperature at the front of molten metal flow shows a downward trend, and the decrease of temperature also has an impact on the flow velocity of molten metal.

Because of the above phenomena, the mathematical model of lost foam casting becomes complex. The essence is that the gas film pressure formed by pattern thermal decomposition has a great impact on the flow of liquid metal front, as well as the selection of process parameters and the quality of lost foam casting. Therefore, mathematical modeling is carried out on the basis of studying the interface displacement of liquid metal flow front in the mold filling process, which plays a vital role in the research of numerical simulation.