1. Optimization of sand casting gating system for mud pump body

According to the simulation results of sand casting process, it is known that the mud pump body poured by the original process does not form an orderly filling from bottom to top during pouring, which is mainly due to the unreasonable sprue size and structural design of the sand casting gating system of the mud pump body, resulting in the filling of the upper inner sprue in advance; During the filling process, the temperature field distribution is not ideal, and there is no temperature gradient distribution towards the top riser, which is mainly due to the limited mold filling cross-sectional area of the upper inner sprue. When the metal liquid level reaches the height of the upper inner sprue, the lower inner sprue continues to fill, resulting in a large amount of high-temperature metal liquid flowing into the casting from the lower inner sprue, making the temperature at the bottom of the casting too high; The size design of sand casting gating system of mud pump body is too small, resulting in long pouring time and large drop of liquid metal temperature. In view of these problems, the sand casting pouring system of mud pump body is improved as follows:

(1) Increase the number of upper ingates, and improve one of the sand casting pouring schemes of the original mud pump body to two;

(2) The upper inner sprue is designed as an inclined upward structure;

(3) Appropriately increase the cross-sectional area of each sprue.

After improving the structure of sand casting gating system of mud pump body, it is necessary to recalculate the size of each sprue. The diameter of the sprue is designed as 150mm, the diameter of the bottom transverse sprue is designed as 160mm, the diameter of the bottom inner sprue is designed as 110mm, the upper transverse sprue is designed as 160mm, and the upper inner sprue is designed as 130mm. The improved sand casting pouring system of the mud pump body is shown in Figure 1.

2. Optimization of feeding system for sand casting of mud pump body

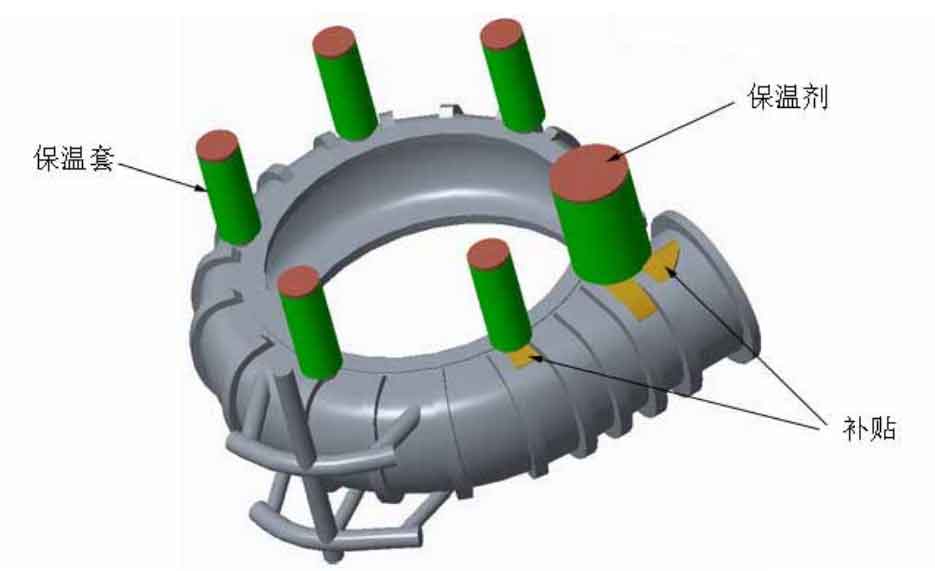

According to the analysis results of solidification process, the feeding distance of riser designed by the original feeding system is insufficient, the feeding efficiency of sand casting of mud pump body is not high, and many isolated liquid phase areas are formed in the casting during solidification, resulting in shrinkage defects in the casting. Optimize the design of the riser in the original sand casting process, improve the ordinary riser used before to the thermal insulation riser, use the material with large thermal conductivity and bulk density as the modeling material of the riser, spray thermal insulation agent on the top surface of the riser at the same time, reduce the heat loss of the riser, and reduce the size while improving the sand casting feeding efficiency of the mud pump body. According to the simulation results, #1 riser and #2-1 riser are solidified in advance during solidification, so that the feeding distance decreases, and shrinkage holes are formed at the casting flange and near the two riser necks. In order to increase the feeding distance, the original process is optimized, and subsidies are set at the two risers to gradually increase the thickness of the casting towards the riser and form a certain temperature difference, To better form sequential solidification. The optimized feeding system is shown in Figure 2.

3. Optimization of sand mold casting cooling system for mud pump body

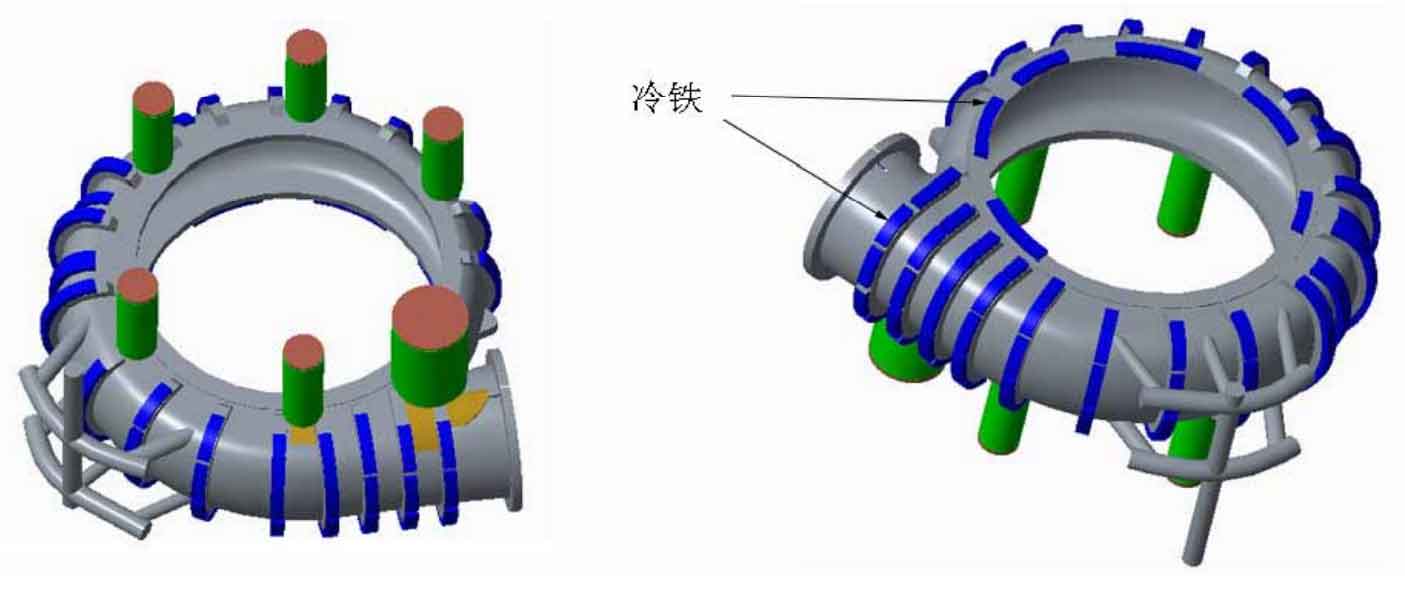

From the analysis of temperature field and stress field during solidification, it can be seen that when the mud pump body sand casting chilling system used in the original process scheme is used together with the riser, the casting does not fully realize sequential solidification. During solidification, the cooling rate at the bottom of the casting is lower than that at the upper part, resulting in shrinkage and porosity defects at the bottom of the casting; At the same time, the cold iron also failed to effectively expand the feeding distance of the riser, #2-2 riser and #2-3 riser exceeded the feeding distance, and shrinkage defects appeared in the part between the two risers; The cooling rate at the bottom of the flange of the mud pump body is lower than that in the neighborhood, and shrinkage defects are generated at the bottom of the flange. At the same time, large stress and deformation are formed at this part, which is easy to crack. Therefore, the sand casting cooling system of the mud pump body designed by the original process is optimized, and the cold iron is set at the bottom of the casting to form a temperature gradient towards the riser during solidification; Place the cold iron in the lower half of the flange to accelerate the local cooling speed and eliminate the shrinkage porosity and hot crack defects in this part; Set cold iron between #2-2 riser and #2-3 riser to form artificial end area, increase feeding distance of riser and eliminate shrinkage defects. The optimized sand casting chilling system of mud pump body is shown in Figure 3.