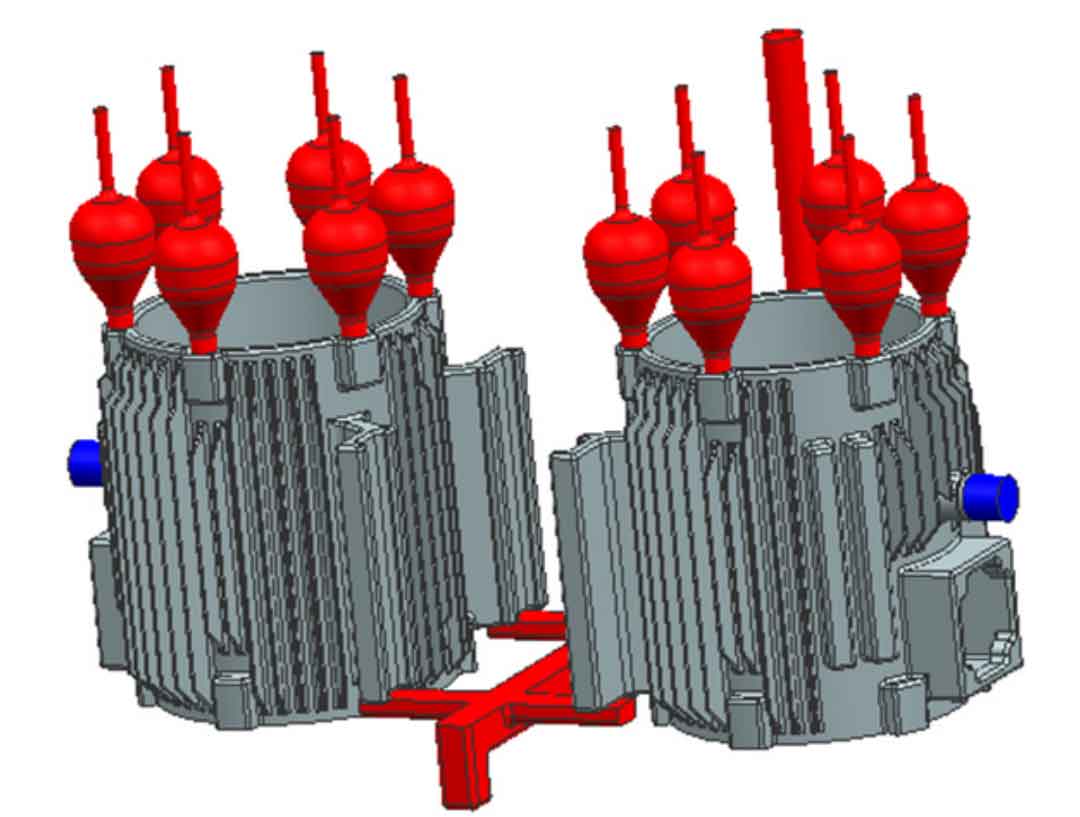

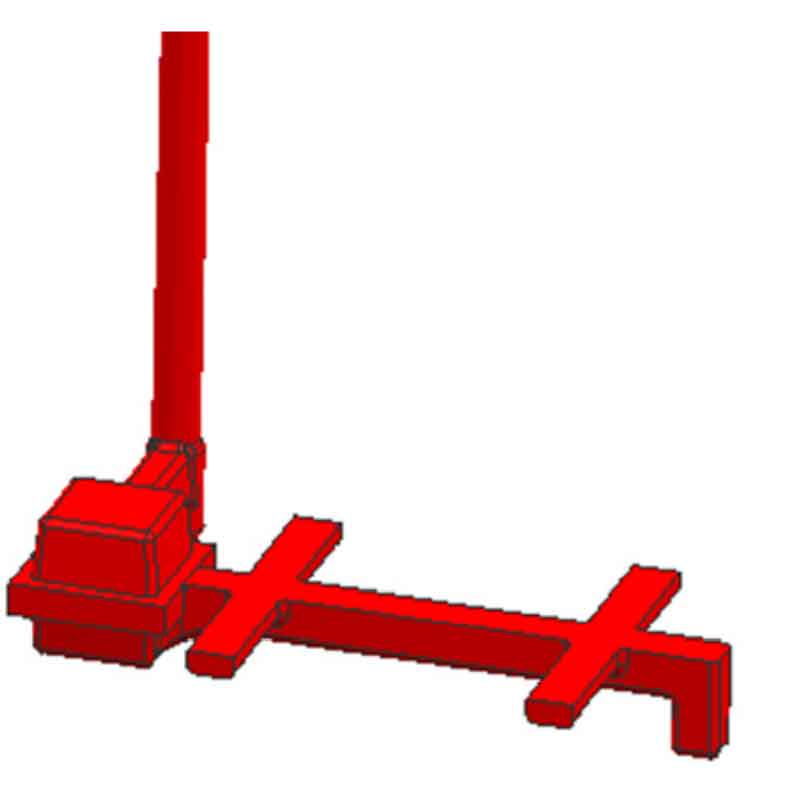

The original process scheme of nodular cast iron is shown in Figure 1, with two pieces in one box. It flows from the two feet of the motor base, adopts an open gating system and two internal sprues. However, the nodular iron castings produced by this scheme have many times that the filling of 4 mm heat dissipation rib plate along the circumference is incomplete, resulting in serious sawtooth cold insulation problems, resulting in the scrapping of nodular iron castings.

Figure 2 shows the nodular iron castings produced by the original process. It can be seen that the meat shortage problem at the axial riser end is more serious than that at the inner sprue end. The farther away from the inner sprue in the radial direction, the more serious the meat shortage problem is. However, the rib filling quality of nodular iron castings near the inner sprue is good and there is no meat shortage problem.

The pouring temperature of the nodular iron casting is 1418 ℃, which is in line with the pouring temperature of this kind of nodular iron casting structure. Based on the material, pouring temperature and defects of the nodular cast iron, the preliminary analysis shows that this defect is mainly caused by the uneven arrangement of the inner sprue and the rapid temperature drop of the molten iron at the far end of the inner sprue during the pouring process, resulting in the uneven distribution of the temperature field and excessive temperature difference of the nodular cast iron during the whole pouring process. At the same time, the thickness of the heat dissipation rib plate of the nodular iron casting is only 4 mm, which belongs to the lowest wall thickness range of sand casting. Therefore, the filling of the nodular iron casting is incomplete, resulting in serrated cold septum, and this defect is more obvious the farther away from the inner sprue in the axial and radial directions.