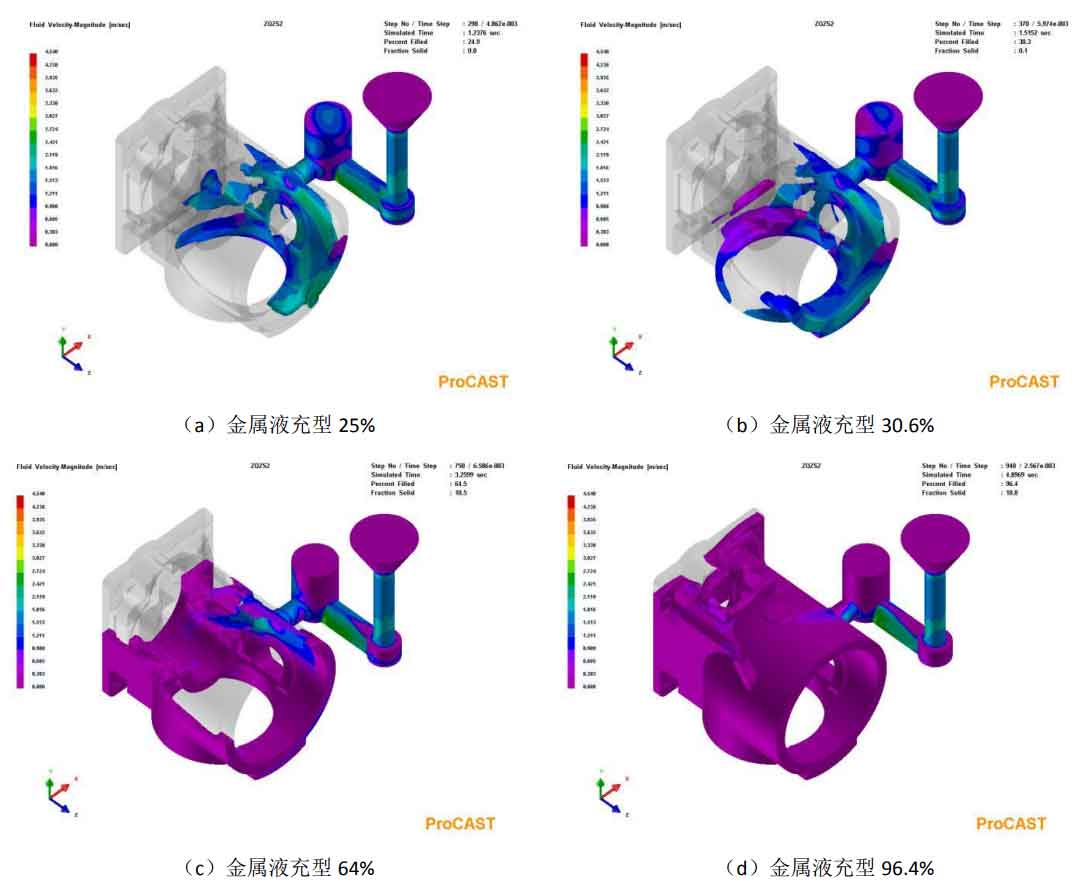

Figures (a) and (b) reflect the flow of liquid metal in the sand casting axle housing when the liquid metal fills the first half of the cavity; Figure (a) is a real-time screenshot of the molten metal just filling the sprue at the beginning of pouring and the molten metal entering the axle housing; The filling ratio of the cavity is 25% and the solidification fraction is 0.0%. Figure (b) reflects the beginning of the flow of the liquid metal in the axle housing when the cavity is filled. The filling ratio of the cavity is 30.3% and the solidification fraction is 0.1%; Figure (c) and figure (d) are screenshots of the middle and late stage of liquid metal filling; Figure (c) is a screenshot of the middle stage of liquid metal filling. The cavity filling ratio is 64% and the solidification fraction is 10.5%; Figure (d) is a screenshot of the later stage of filling the cavity with liquid metal. The filling ratio of the cavity is 96.4% and the solidification fraction is 18.8%. During pouring, under the action of gravity, the liquid metal first enters the mold cavity through the sprue, enters the transverse sprue and inner sprue, and finally enters the filling of the mold cavity of the sand casting axle housing. The whole process of sand casting axle housing.

It can be seen from the velocity field in the figure that during the filling process of the mold cavity, the runner flow is unstable as a whole. There are many isolated metal liquids in figure (b), which are prone to defects such as cold shut-off and cold beans. The liquid metal is in an unsaturated state in the sprue and has little filtering effect on the molding sand, so that sand holes and other casting defects may occur in the sand casting axle housing. In the whole filling process of molten metal, the filling rate of each sand casting bridge shell varies greatly, and the melt flow is turbulent. In figure (c) and figure (d), the solidification fraction accounts for a large proportion, which leads to a temperature difference of 150 ℃ at the final solidification position of sand cast axle housing, resulting in incomplete coincidence and cold shut defects, which is obvious.