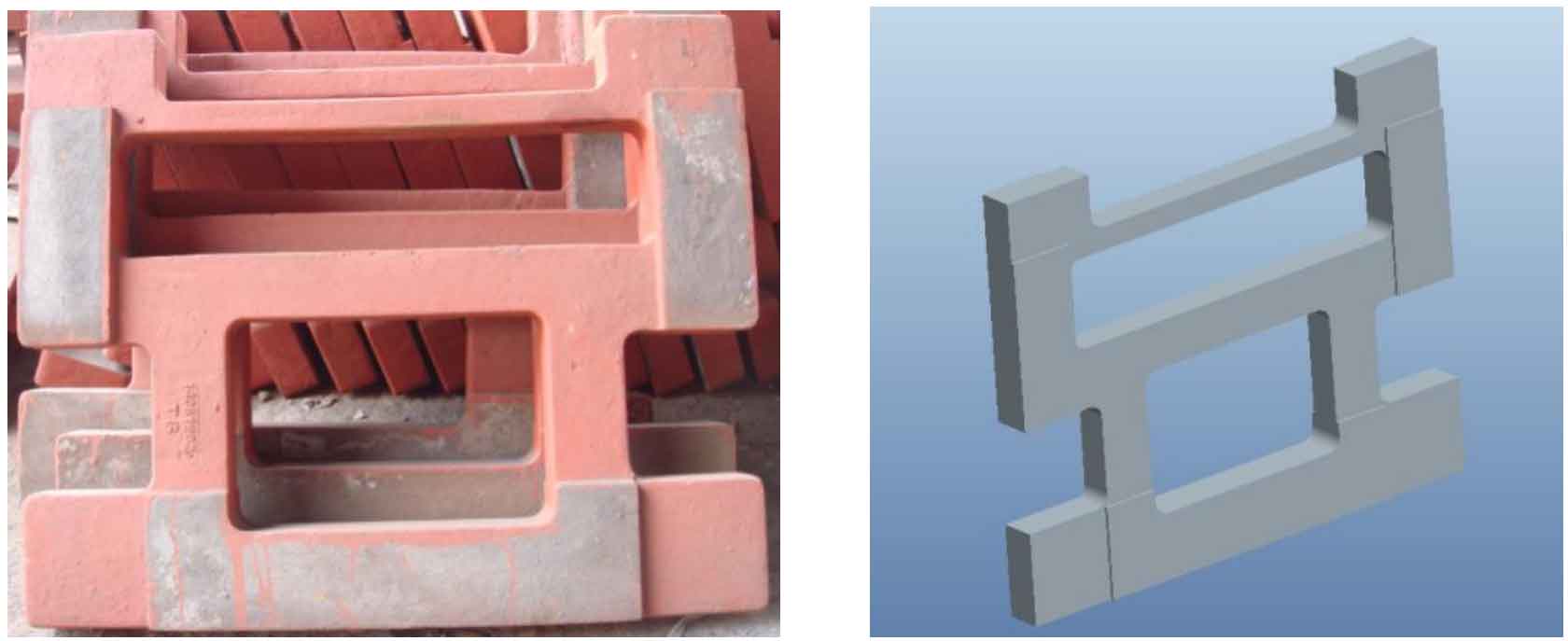

Gray iron pressure bearing part is the underframe of an elevator. It is used to fix the traction motor of the elevator. It needs to bear the weight pressure brought by the equipment itself. The underframe is a rectangular lost foam casting. There is a cavity to be cast in the middle. The cavity that plays a fixed role does not need to be cast (as shown in the figure). The lost foam casting process is adopted to give play to the advantages of flexible product design freedom and no core, which can reduce the processing cost and improve the production efficiency. The three-dimensional outline dimension of the part is 770mm × 640mm × 60mm, lost foam casting weighs about 114kg, and the material is HT150.

The pressure bearing part has simple structure and uniform wall thickness. In order to reduce the production cost, the lost foam casting process which can meet the performance requirements and directly produce castings by making iron with water slag iron is used for production.

The lost foam casting is a load-bearing part with large stress. It is required that the internal structure of the lost foam casting is dense and there shall be no serious hole defects. At the same time, the surface shall be free of cold lap, crack, shrinkage cavity, penetrating defects and serious defects (such as under casting, mechanical damage, etc.).