According to the forming and manufacturing process of output shaft shell, different casting enterprises adopt different molding lost foam process methods to give full play to their own advantages to meet the quality requirements of this kind of products. According to the operating conditions of the output shaft housing product, its service performance requires that the product shall not have any shrinkage and porosity defects. At present, the common production methods of output shaft shell mainly include clay sand manual molding lost foam casting, self hardening resin sand manual molding lost foam casting and static pressure molding lost foam casting, which are determined according to the enterprise’s own conditions.

1. Lost foam process of clay sand manual molding

At present, clay sand manual molding lost foam casting is one of the main molding lost foam casting production methods of output shaft shell. This process method has simple production facilities and low investment, but it occupies a large area, high labor intensity, low production efficiency and poor environmental conditions. The output shaft shell casting produced by lost foam casting with clay sand has some problems, such as large thickness of flanges at both ends, high proportion of shrinkage defects, large weight deviation, large size fluctuation and poor surface quality after processing.

2. Self hardening resin sand manual molding lost foam process

At present, the manual molding lost foam casting of self hardening resin sand is also a main molding lost foam casting production mode of output shaft shell. The output shaft shell casting produced by this process has good surface quality and stable size. In comparison, this process has small equipment investment and generally good product quality. However, due to intermittent operation, it has low production efficiency, high labor intensity and large site area.

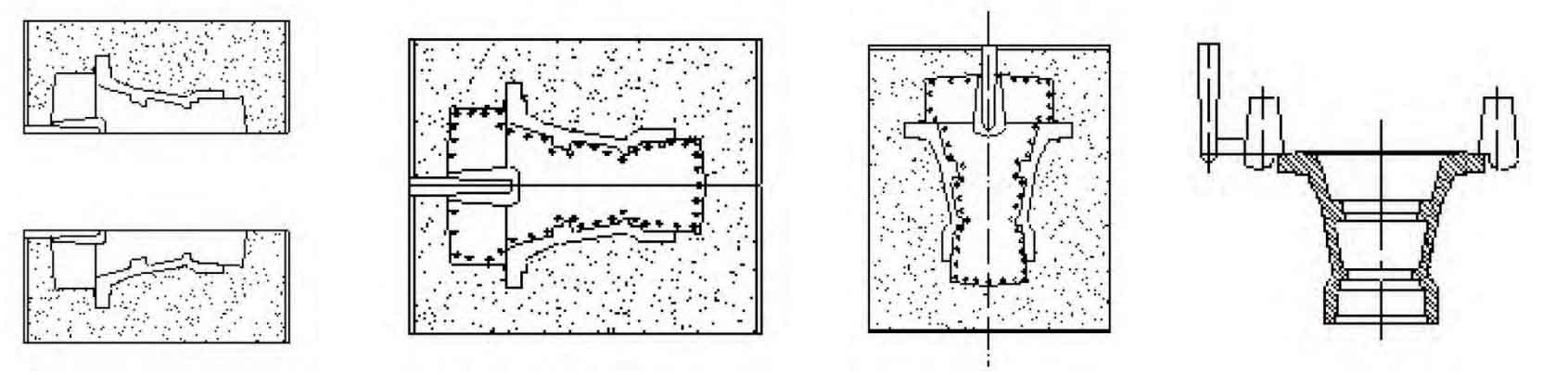

For the output shaft shell casting produced by the self hardening resin sand manual molding lost foam casting, shrinkage cavity and porosity defects still occur at the thick parts of the flanges at both ends, and the internal quality stability and consistency of the product need to be improved. The casting defects at the flange end are shown in Figure 1.

3. Static pressure molding lost foam process

The combined process of “static pressure molding + self hardening resin sand core making” is used to produce the output shaft shell by static pressure molding lost foam casting process. In order to solve the problem of shrinkage cavity and porosity in the thick part of the flange, the ring cold iron is embedded in the corresponding resin sand core to achieve the chilling effect. However, due to the high static pressure head of the feeding riser, the process yield is relatively low. Because the process requires large resin sand cores, which are large and heavy, and have a long-term production, it has a great impact on the molding sand quality of the static pressure production line system, either affecting the product quality, or the production cost due to the elimination and replacement of old sand. Due to the imbalance of the sand system caused by the “overflow” of old sand, the contradiction of solid waste discharge is prominent.

In addition, according to statistics, after the development and production of output shaft shell, some work department equipment of the company’s static pressure automatic line, such as unpacking sand remover, grid sand remover cracking and scale conveyor failure at all levels, have increased significantly, which is related to the weight of single casting of output shaft shell.

4. Horizontal and vertical casting forming process

In view of the internal quality and process problems of the product caused by the horizontal molding of the output shaft shell and the horizontal pouring of the lost foam casting, the resin sand “horizontal mold and vertical pouring” process method is designed. The horizontal parting and vertical pouring diagram of the output shaft shell is shown in Figure 2. Under the condition of single resin sand, horizontal parting and horizontal core are not only simple to operate, but also low labor intensity, which ensures the production efficiency. The vertical pouring greatly improves the static head of the product itself. At the same time, the vertical pouring is combined with the blank holder riser pouring feeding system to realize the bottom-up sequential feeding of the forming and solidification of the product itself under gravity, and the flange at the top gets the most beneficial and economical forming and solidification feeding under the temperature gradient, Furthermore, the defects of shrinkage cavity and looseness in the thick parts of the flanges at both ends of the output shaft shell are solved from the process, so as to ensure the internal quality of the product.

The lost foam casting molding process can effectively solve the defects of shrinkage cavity and porosity in the thick parts of the flanges at both ends of the output shaft shell. However, because it is based on the resin sand process, it has the problems of high cost, low production efficiency, high labor intensity, large occupied area and poor operating environment.

5. Lost foam casting forming process

Considering the influence of environmental protection, product structure, safety performance, appearance quality, production efficiency and cost, the lost foam casting forming process with advantages in development and test is determined.