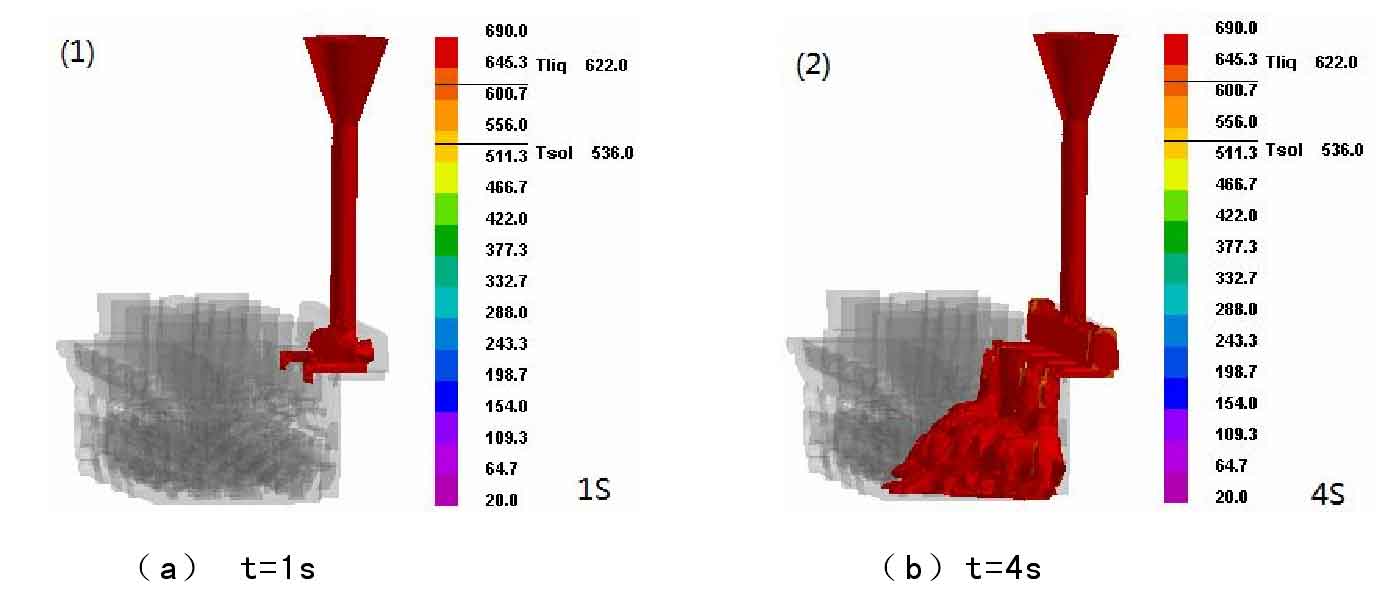

The first Pouring Scheme of cylinder head – the temperature field distribution of sand casting with single side top injection inner gate during mold filling is shown in Figure 1. It can be seen from the figure that the molten metal can smoothly fill the mold cavity without defects such as insufficient pouring. The total filling time of sand casting is about 15s. During the mold filling process of sand castings, the liquid metal flows through the runner and inner runner from the gate cup under the action of gravity and enters the mold cavity. At the beginning, it is dispersed into the mold cavity by multiple inner gates, avoiding the occurrence of too fast and direct sand flushing. It shows that the position of inner gate here can meet the requirements of mold filling of sand castings. When the mold filling of sand casting reaches 8s, the metal liquid at the bottom of the metal liquid is basically at the same level, and then rises slowly and steadily until the mold cavity is filled without obvious air entrainment.

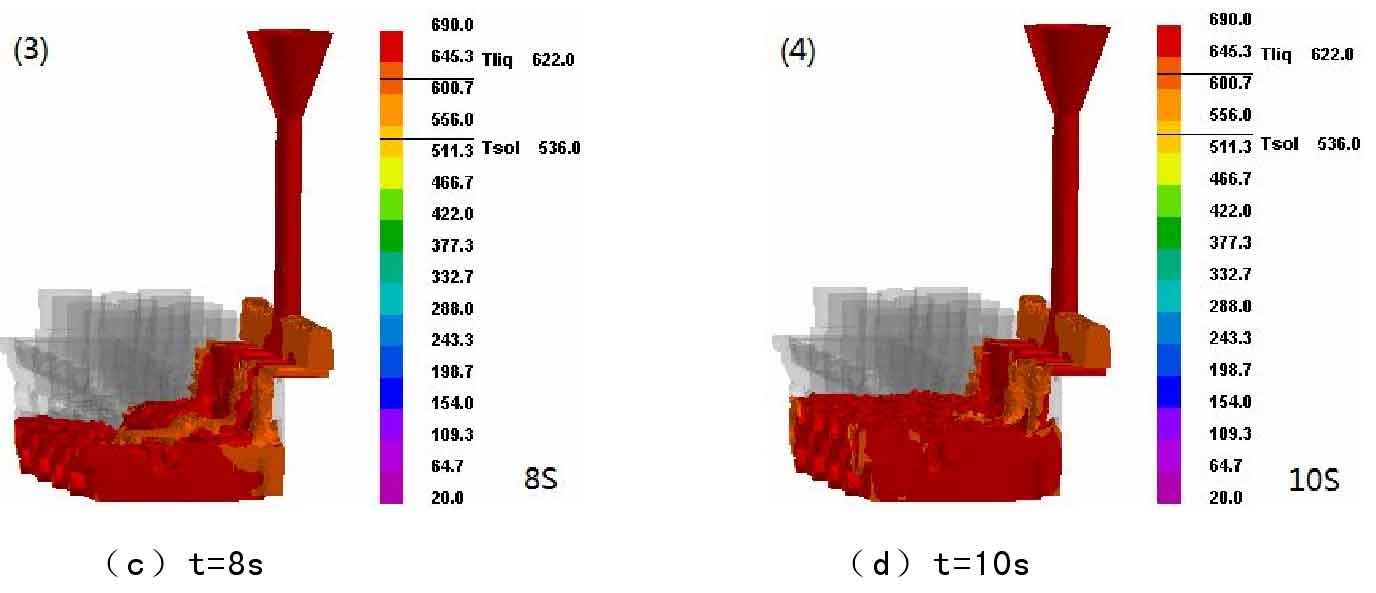

Figure 2 shows the time distribution of liquid metal filling each part of the mold cavity. It can be seen that in the initial stage, even at the same horizontal position, the filling time of the bottom layer is different due to the use of one-sided gating system. Before 40% mold filling of sand castings, the first filling time of liquid metal on the side close to the opening position of the inner gate is short, and the filling time of liquid metal on the opposite side of the mold is long. However, when reaching the middle and upper layers, the filling time of sand castings at the same level is basically the same, and the filling of sand castings is relatively stable.