The hook tongue adopts the improved sand casting process scheme to simulate the mold filling and solidification process. The pouring time is 18S, the interface heat transfer coefficient between the insulation riser and the sand mold is 100W / (M2 · K), and other settings remain unchanged.

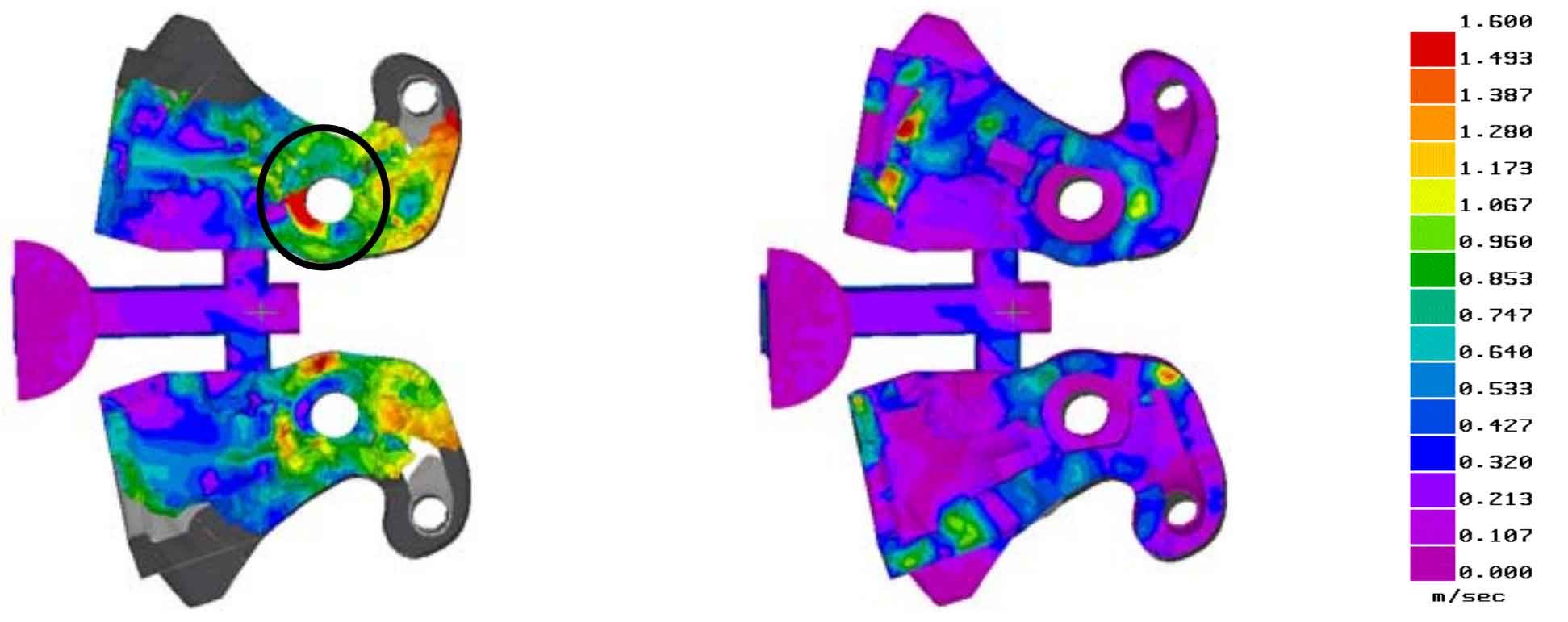

During the mold filling process of sand casting, it can be seen from Figure 1 that in addition to the large front speed of liquid steel, the speed around the pin hole is uniform and not easy to be eroded, which can effectively avoid the occurrence of sand flushing, slag inclusion and sand sticking defects.

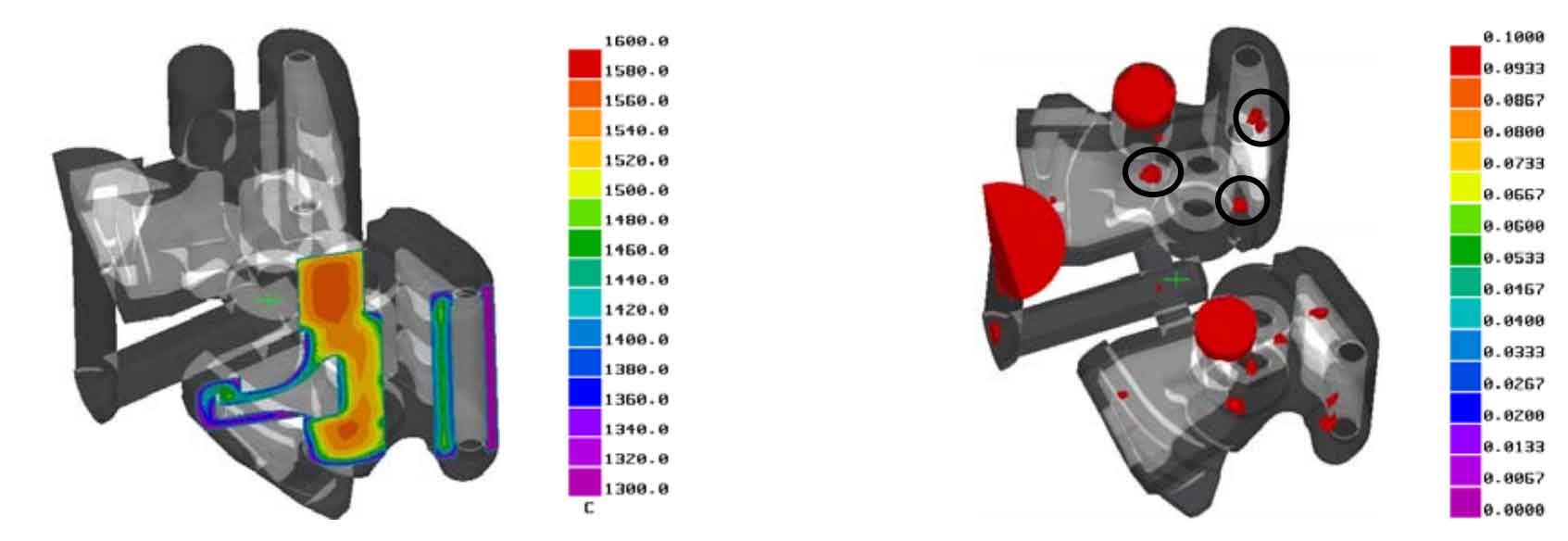

During the solidification process of sand casting, figure 2 shows the temperature distribution diagram of longitudinal section. The liquid steel between the riser and the inner wrist surface of the hook tongue and the pressure push table with large wall thickness is unobstructed, which can carry out effective feeding, so as to reduce the generation of shrinkage porosity; Figure 3 shows the prediction results of shrinkage porosity. After the improved process is adopted, the shrinkage porosity at the guard pin flange and traction flange is transferred to the middle of the hook tongue to avoid the main stress parts. The shrinkage porosity in other parts is basically the same as the original process.

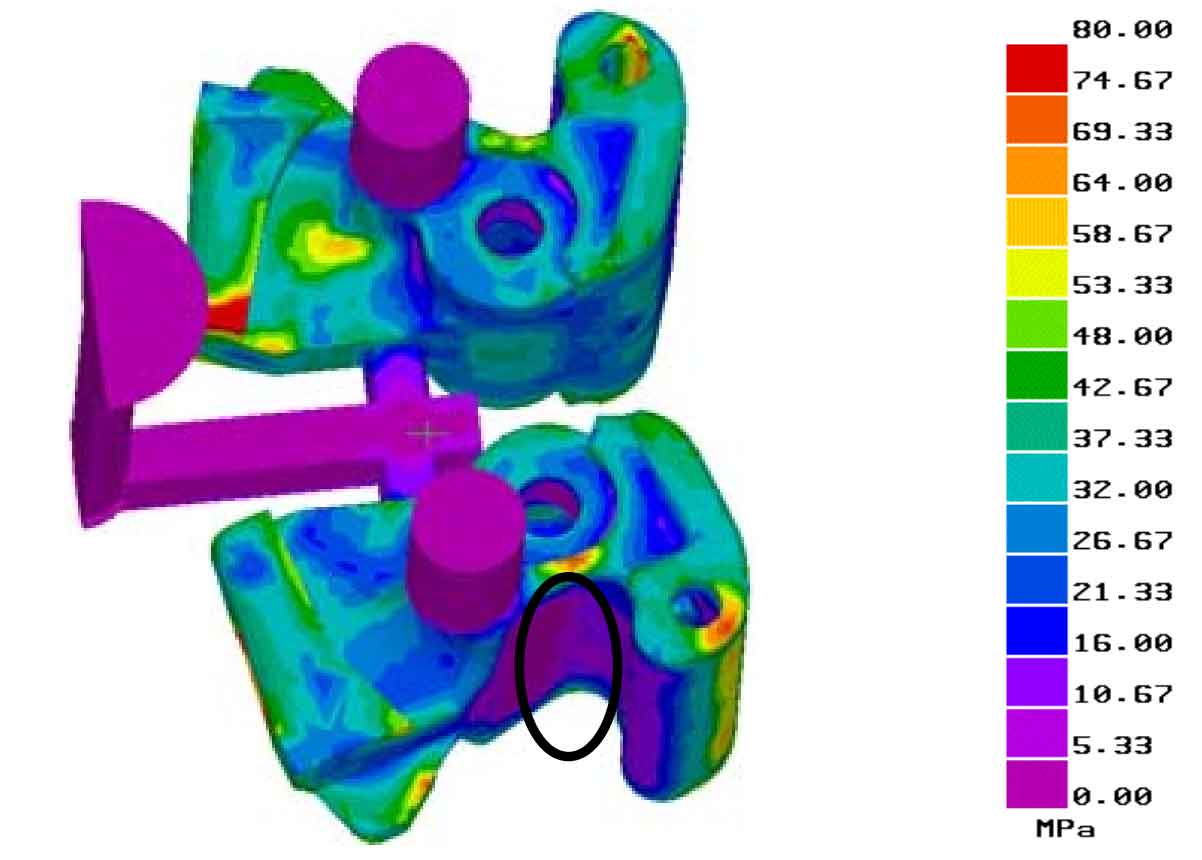

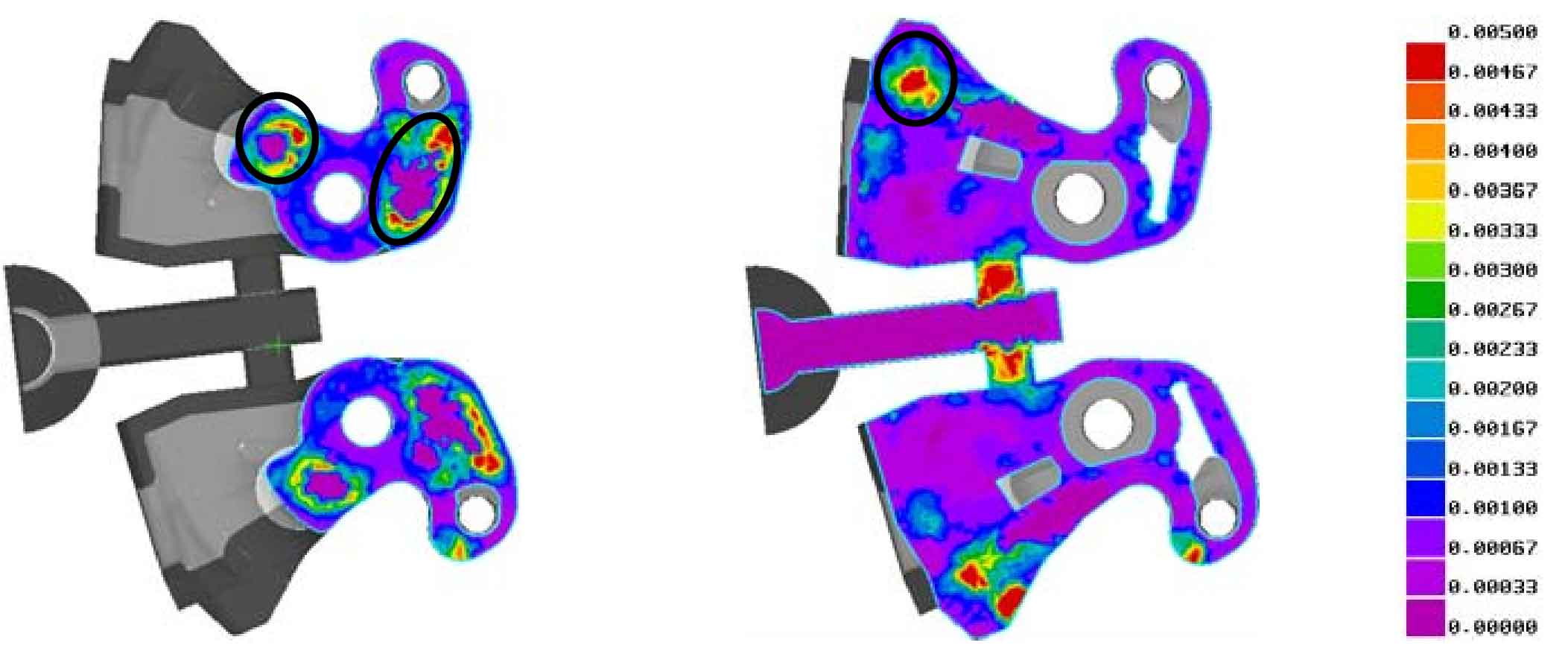

Figure 4 and figure 5 show the simulation results of stress field of hook tongue improved process. According to the simulation results of equivalent stress after 30 s solidification of the hook tongue in Figure 4, the overall stress level of the hook tongue is slightly higher than that of the original sand casting process, but the stress of key parts such as the inner wrist surface of the hook tongue is small, and the parts with large stress are basically the same as that of the original process. It can be seen from the simulation results of hot crack in Figure 5 that the hot crack tendency at the inner corner of traction flange, coupler tail stop and coupler wrist is still large, which is slightly better than the original process.