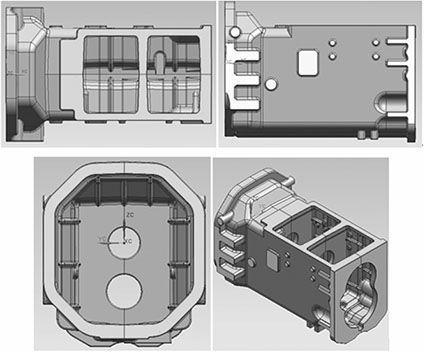

Lost foam casting has many advantages, such as low production cost, good surface quality, high dimensional accuracy, and low environmental pollution. However, the design of the lost foam casting process is more difficult compared to sand casting, as the presence of negative pressure during the lost foam casting process results in significant differences in the filling and cooling processes compared to sand casting. Therefore, there are significant differences between the design ideas of the gating system and sand casting. Using computer numerical simulation technology to simulate the entire process of lost foam casting can help technicians judge the superiority and inferiority of the process plan. After 3D visualization processing of the simulation results, technicians can intuitively analyze the filling and solidification characteristics of the process plan, and make judgments based on this to optimize the process. In this way, targeted process experiments can be conducted to reduce the number of processes The number of experiments can shorten the development cycle and reduce development costs. The emergence of numerical simulation technology in casting has led casting from semi empirical and semi theoretical to a visualized and controllable development path, which is the direction of modern process design development. The front box of a certain model of tractor transmission system is one of the main products of the KW line of Yituo Company. It has a large batch size, complex structure, large volume, heavy weight, and small minimum wall thickness, making it very difficult to cast in lost foam. stay In the process of casting process design, a casting simulation system is used to simulate the three designed process schemes separately, comprehensively analyze the advantages and disadvantages of each scheme, and obtain the optimal process scheme through process optimization.

The overall size of the box is large and the wall thickness is small. When using lost foam casting, deformation should be considered first, followed by cold insulation. Deformation can be prevented and controlled through strict process control, reasonable pouring system and anti deformation measures, and reasonable sand molding technology. Cold insulation can be solved through reasonable gate position and higher pouring temperature.

To ensure the efficiency and success of future process trials Three disappearing mold process schemes were designed and corresponding ones were carried out

Simulate and verify the rationality of the process plan.

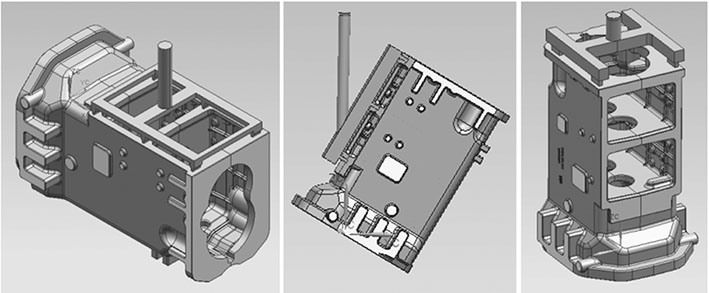

Simulation results of Scheme 1: In the later stage of solidification, slag inclusion and shrinkage defects appear at the marked positions in the figure, and an overflow structure needs to be added. In addition, due to the flat placement, the flat part of the component is located below, which can easily cause box collapse. Therefore, during the compaction process, attention should be paid to adding sand and compacting multiple times, and pouring should be done quickly during the pouring process. And during the styling process, due to size constraints, only one box per piece can be used, and the box weight is relatively small.

Compared with scheme 1, scheme 2 has a smaller tendency for slag inclusion and shrinkage, while also reducing the risk of box collapse. However, the inclined placement makes it difficult to add sand and compact the material, requiring multiple sand additions and low-frequency vibration. During the styling process, due to size constraints, only one box per piece can be used, and the box weight is relatively small.

Scheme 3 and Scheme 2 have the same characteristics and can achieve casting of 1 box with 2 pieces. The box is large and efficient, but the filling process is more chaotic.

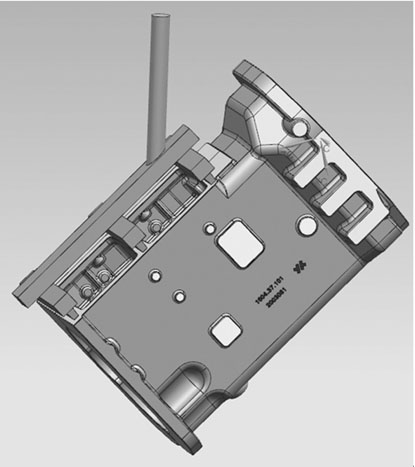

Based on the advantages and disadvantages of three process schemes, as well as the actual situation of the lost foam production line on site, a comprehensive analysis was conducted to adopt the intermediate process scheme, and mold assembly and pouring tests were carried out.

Using a 3D scanner to scan the sample blank, a 3D model of the blank is obtained. The deformation and machining allowance of the blank are detected by comparing the 3D model of the blank with the theoretical 3D model in full size. The 3D model of the blank is almost completely consistent with the theoretical model, and no parts with significant deformation are found. The deformation is within the process control range. In order to further verify the deformation and processing conditions of the sample blank, the sample blank was subjected to processing identification. The results showed that the deformation of the sample was small, within the process control range, and no other defects were found. The sample was qualified.

The development cycle of lost foam new products is relatively long. In the process design stage, a casting simulation system is used to simulate the proposed process. Technical personnel can intuitively analyze the advantages and disadvantages of each process plan, which is convenient for later process optimization.