Spheroidal Graphite Cast Iron is renowned for its excellent mechanical properties, including high tensile strength, ductility, fatigue resistance, and wear resistance. These properties make Spheroidal Graphite Cast Iron an ideal material for various demanding applications in the electric vehicle and heavy machinery industries. This article explores the specific uses of Spheroidal Graphite Cast Iron in these industries and highlights the benefits it brings to different components and systems.

Properties of Spheroidal Graphite Cast Iron

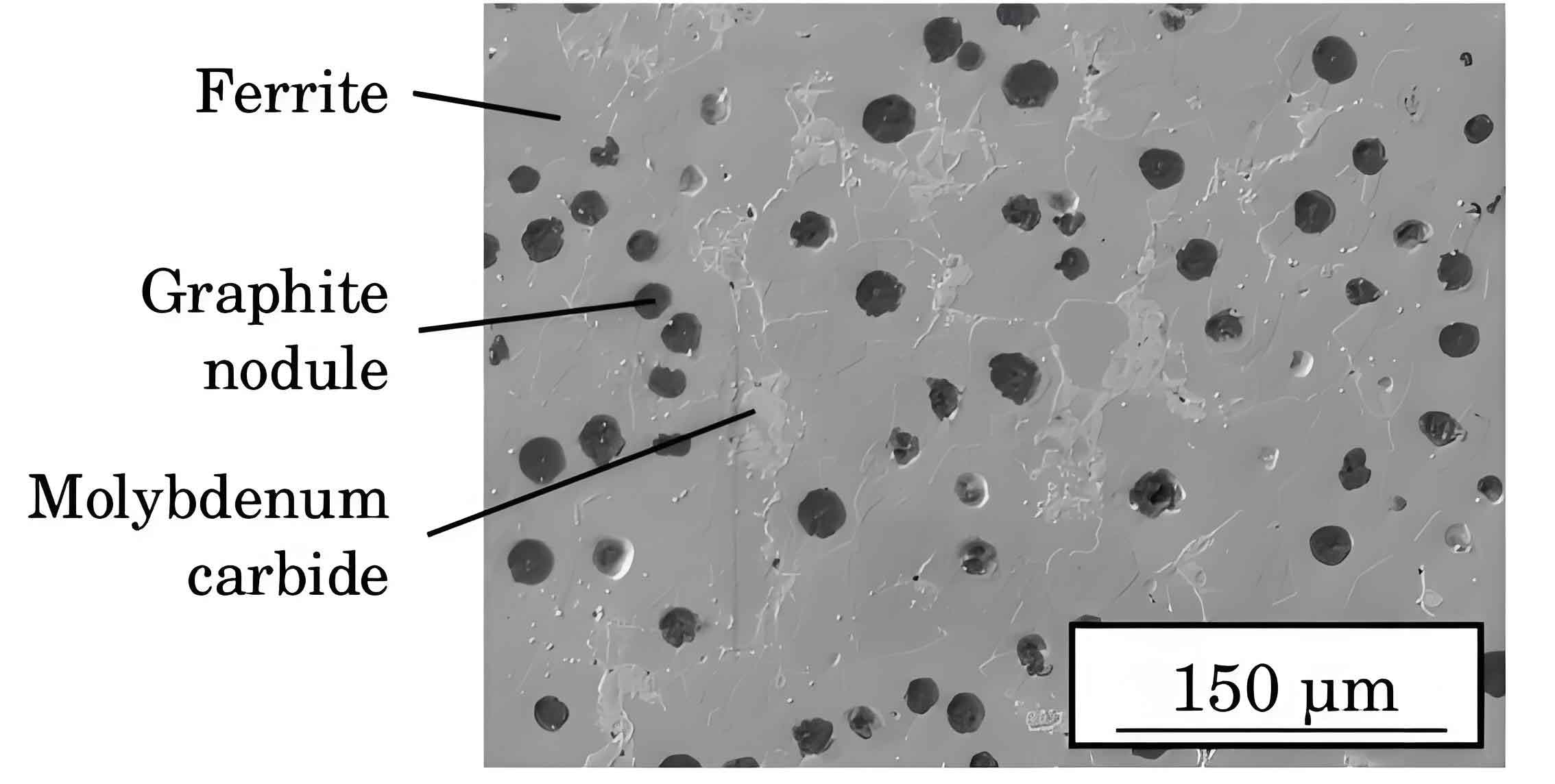

The unique properties of Spheroidal Graphite Cast Iron stem from its microstructure, characterized by spherical graphite nodules dispersed within a metallic matrix. This structure significantly enhances its performance compared to traditional gray cast iron.

Key Properties

- High Tensile Strength: Provides the ability to withstand high loads without failure.

- Excellent Ductility: Allows for deformation without cracking, essential for impact resistance.

- Fatigue Resistance: Withstands repeated loading cycles, making it suitable for dynamic applications.

- Wear Resistance: Resists surface wear, crucial for components subjected to friction.

Table 1: Key Properties of Spheroidal Graphite Cast Iron

| Property | Description |

|---|---|

| High Tensile Strength | Ability to withstand high loads without failure |

| Excellent Ductility | Deformation without cracking |

| Fatigue Resistance | Withstands repeated loading cycles |

| Wear Resistance | Resists surface wear |

Applications in the Electric Vehicle Industry

The electric vehicle industry demands materials that offer a combination of strength, durability, and light weight. Spheroidal Graphite Cast Iron meets these requirements and is used in various critical components of electric vehicles.

1. Electric Motor Housings

Electric motor housings must be robust to protect the motor from mechanical and environmental stresses. Spheroidal Graphite Cast Iron provides the necessary strength and thermal conductivity.

Benefits

- Strength and Durability: Ensures long-lasting protection for electric motors.

- Thermal Conductivity: Helps in efficient heat dissipation, maintaining optimal motor temperatures.

List 1: Benefits of Spheroidal Graphite Cast Iron in Electric Motor Housings

- Strength and durability for motor protection.

- Efficient thermal conductivity for heat dissipation.

2. Battery Housings

Battery housings in electric vehicles require materials that can protect batteries from impact and thermal stresses. Spheroidal Graphite Cast Iron offers excellent impact resistance and thermal management properties.

Benefits

- Impact Resistance: Protects batteries from mechanical shocks.

- Thermal Management: Aids in maintaining stable battery temperatures.

3. Suspension Components

Suspension components in electric vehicles benefit from the high strength and ductility of Spheroidal Graphite Cast Iron. These properties help absorb shocks and stresses from the road.

Benefits

- High Strength: Withstands dynamic loads and impacts.

- Ductility: Provides flexibility and resilience.

Table 2: Applications of Spheroidal Graphite Cast Iron in Electric Vehicles

| Component | Benefits |

|---|---|

| Electric Motor Housings | Strength, durability, thermal conductivity |

| Battery Housings | Impact resistance, thermal management |

| Suspension Components | High strength, ductility |

Applications in the Heavy Machinery Industry

The heavy machinery industry requires materials that can handle extreme loads, wear, and environmental conditions. Spheroidal Graphite Cast Iron is extensively used in this industry due to its robust mechanical properties.

1. Engine Components

Engine components such as crankshafts, camshafts, and connecting rods benefit from the high tensile strength and fatigue resistance of Spheroidal Graphite Cast Iron.

Benefits

- High Tensile Strength: Ensures durability and performance under high loads.

- Fatigue Resistance: Withstands cyclic loading and prolongs component life.

List 2: Benefits of Spheroidal Graphite Cast Iron in Engine Components

- High tensile strength for durability.

- Fatigue resistance for extended service life.

2. Hydraulic Components

Hydraulic components, including pumps, cylinders, and valves, require materials with excellent wear resistance and strength. Spheroidal Graphite Cast Iron meets these requirements, ensuring reliable operation under high pressure.

Benefits

- Wear Resistance: Extends the life of hydraulic components.

- Strength: Withstands high-pressure conditions.

3. Structural Parts

Structural parts in heavy machinery, such as frames and supports, demand materials with high load-bearing capacity and impact resistance. Spheroidal Graphite Cast Iron provides these properties, making it suitable for such applications.

Benefits

- Load-Bearing Capacity: Supports heavy loads without deformation.

- Impact Resistance: Absorbs shocks and stresses from operational conditions.

Table 3: Applications of Spheroidal Graphite Cast Iron in Heavy Machinery

| Component | Benefits |

|---|---|

| Engine Components | High tensile strength, fatigue resistance |

| Hydraulic Components | Wear resistance, strength |

| Structural Parts | Load-bearing capacity, impact resistance |

Advancements in Spheroidal Graphite Cast Iron for Enhanced Performance

Recent advancements in the production and processing of Spheroidal Graphite Cast Iron have further enhanced its performance, making it even more suitable for demanding applications in electric vehicles and heavy machinery.

1. Alloying and Inoculation

Optimizing alloying elements and inoculation techniques has improved the mechanical properties and consistency of Spheroidal Graphite Cast Iron.

Key Advances

- Enhanced Alloying: Addition of elements like copper, nickel, and molybdenum to improve strength, toughness, and wear resistance.

- Advanced Inoculation: Improved methods for producing uniform and spheroidal graphite nodules.

List 3: Key Advances in Alloying and Inoculation

- Enhanced alloying with copper, nickel, and molybdenum.

- Advanced inoculation techniques for uniform graphite nodules.

2. Heat Treatment Processes

Advanced heat treatment processes such as austempering and normalizing have refined the microstructure of Spheroidal Graphite Cast Iron, enhancing its mechanical properties.

Key Processes

- Austempering: Produces a bainitic microstructure, improving strength and toughness.

- Normalizing: Refines the grain structure, enhancing overall mechanical properties.

Table 4: Advanced Heat Treatment Processes

| Process | Benefits |

|---|---|

| Austempering | Bainitic microstructure for improved strength and toughness |

| Normalizing | Refined grain structure for enhanced mechanical properties |

Conclusion

Spheroidal Graphite Cast Iron plays a crucial role in the electric vehicle and heavy machinery industries due to its superior mechanical properties. Its high tensile strength, excellent ductility, fatigue resistance, and wear resistance make it ideal for critical components such as electric motor housings, battery housings, suspension parts, engine components, hydraulic parts, and structural components. Advancements in alloying, inoculation, and heat treatment processes have further enhanced its performance, ensuring that Spheroidal Graphite Cast Iron continues to meet the evolving demands of these industries. As technology advances, the potential applications and benefits of Spheroidal Graphite Cast Iron are likely to expand, contributing to the development of more efficient and durable electric vehicles and heavy machinery.