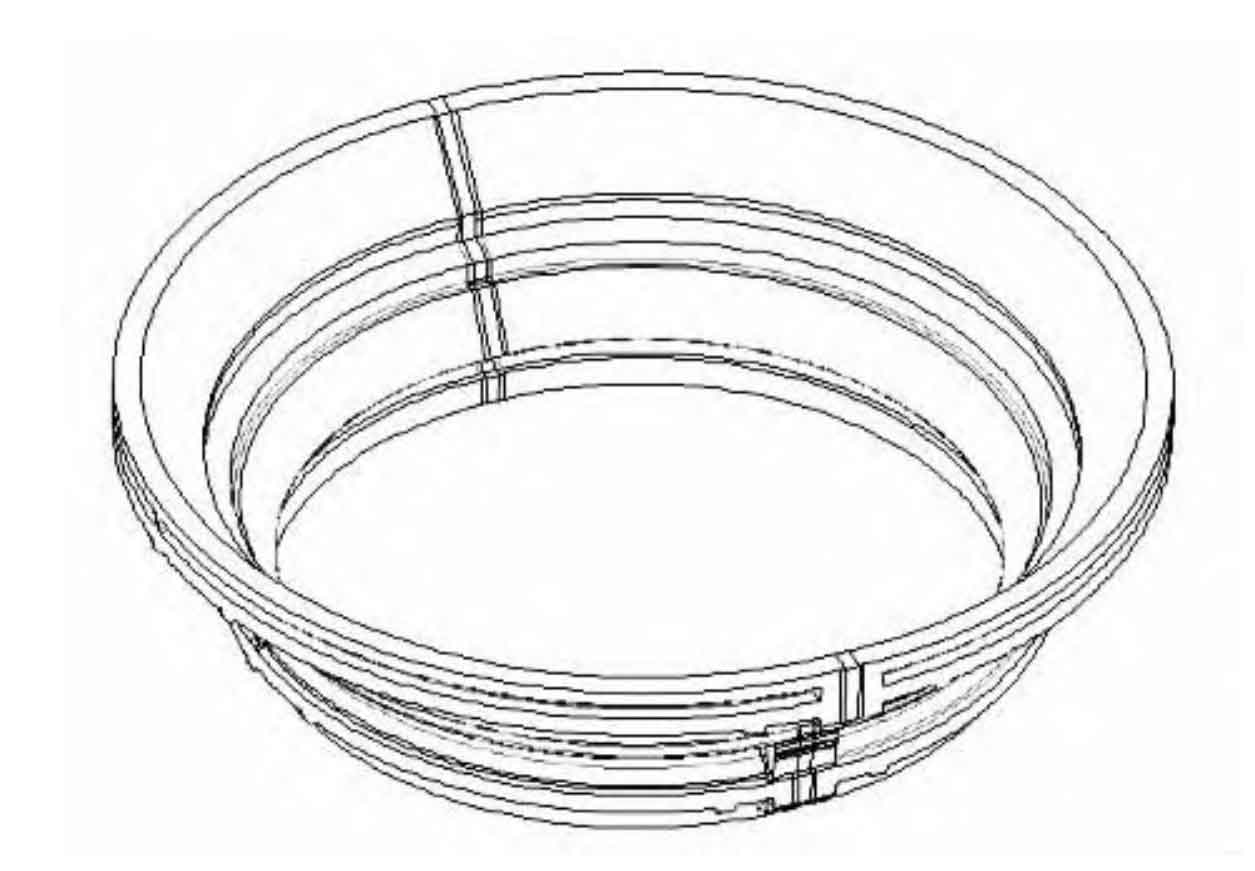

In the traditional sand casting field of steel castings and iron castings, resin sand and wood mold are generally used to mold in the sand box to form the cavity of the sand casting products, and the sand casting blank is obtained after pouring molten metal. The traditional sand box shape is the standard specification of rectangular quadrilateral or other shapes, and the matching casting shape is not limited. The gap between the casting and the sand box is filled with resin sand during casting, and the cost of filled resin sand is one of the main raw and auxiliary material costs in sand casting. The purpose is to make a sand-iron ratio tooling that can be disassembled and assembled flexibly, and repeatedly fill the gap between the casting and the sand box during casting, so as to save the cost of resin sand.

The application of this tool in sand casting has the following advantages:

1) The operation is light and simple. The single block can be handled manually, or it can be lifted by using the round hole on the standard block after assembly.

2) High versatility. The standard block structure can be used to assemble the tooling suitable for its shape and specification according to the product structure. It is suitable for enterprises producing single small batch castings.

3) Reuse. All tooling can be recycled and reused after pouring. The pin is the main stress part, which can be replaced after damage, and the reuse cost is low.