According to the theory of heat transfer, the process of sand casting high-temperature metal from pouring into the mold to solidification is mainly carried out through three ways: heat transfer from high-temperature metal to the mold, convective heat transfer between metal liquid and mold and radiation heat transfer from metal liquid to mold.

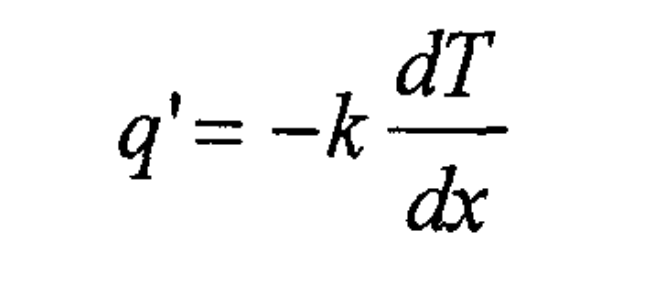

1) Heat conduction: when there is no relative displacement between parts of an object, the heat transfer process generated by the thermal movement of micro particles such as molecules, atoms and free electrons is called heat conduction. It follows Fourier’s Law:

Where:

Q ‘- heat flux

K – thermal conductivity

The minus sign in the formula indicates the direction of heat flow and temperature drop.

In the process of sand casting, there is heat conduction between castings and sand mold, between castings and cold iron, and between cold iron and sand mold.

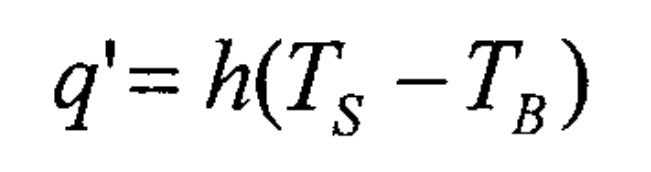

2) Thermal convection: thermal convection refers to the heat transfer process of fluid (liquid or gas) in motion. In the process of sand casting, there is heat convection between molten metal and the inner wall of the mold, between molten metal and the outer wall of the mold and the atmosphere. Newton’s cooling law is usually used to describe thermal convection:

Where:

H-convective heat transfer coefficient

TS – solid temperature

TB – fluid temperature

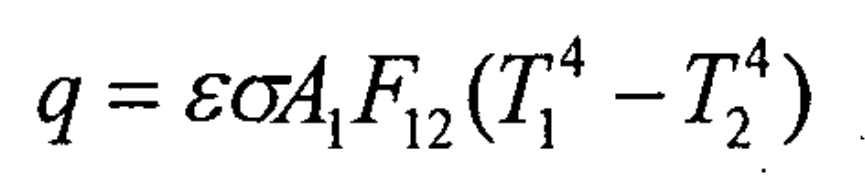

3) Thermal radiation: thermal radiation refers to the exchange process in which electromagnetic energy emitted by an object is absorbed by another object and then transformed into heat energy. The net heat transfer between the two is calculated by Stephen Boltzmann equation:

Where:

Q – heat flux

ε— Emissivity

σ— Stephen Boltzmann constant

A1 – surface area of radiation surface 1

F12 – shape factor

T1, T2 – absolute temperature of radiation surface 1 and 2.