In order to reconfirm the defects of the nodular iron casting and the rationality of the analysis results, the CAE filling simulation of the original process scheme was carried out. The filling parameters of nodular iron castings are set as pouring mass of 87 kg, pouring temperature of 1420 ℃ and filling time of 15 s.

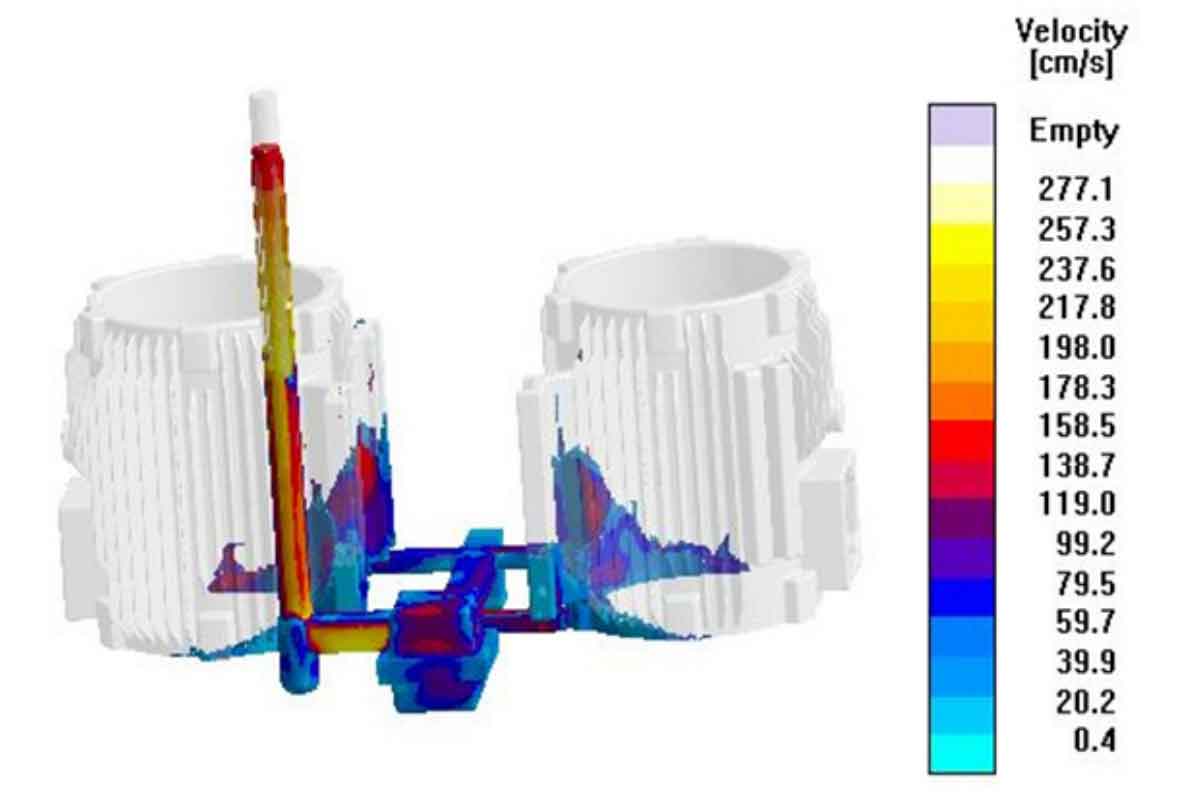

Fig. 4 and Fig. 5 are the simulation results of molten iron flow rate and temperature field in the mold filling process of the original ductile iron process. Through CAE simulation of the original scheme, from the filling results, at the beginning, the flow rate of molten iron near the inner sprue is high and splashing occurs, resulting in unstable filling of molten iron in the mold. At the same time, from the distribution of temperature field in the filling process of nodular iron castings, it can be found that the temperature of the farthest filling process is low and the temperature difference of contour surface is large, In particular, the temperature difference between the inner sprue side and the farthest contour surface is even higher than 100 ℃, which greatly affects the filling of the farthest thin-walled heat dissipation rib plate, resulting in poor molding problems such as lack of meat and cold lap of nodular iron castings.