For the simulation of nodular iron castings, the following simulation test is carried out by taking the actual nodular iron castings produced by ZHY Casting as an example. The quality of this nodular iron castings requires that the casting surface is smooth, and the nodular iron castings are not allowed to have defects such as pores and cracks.

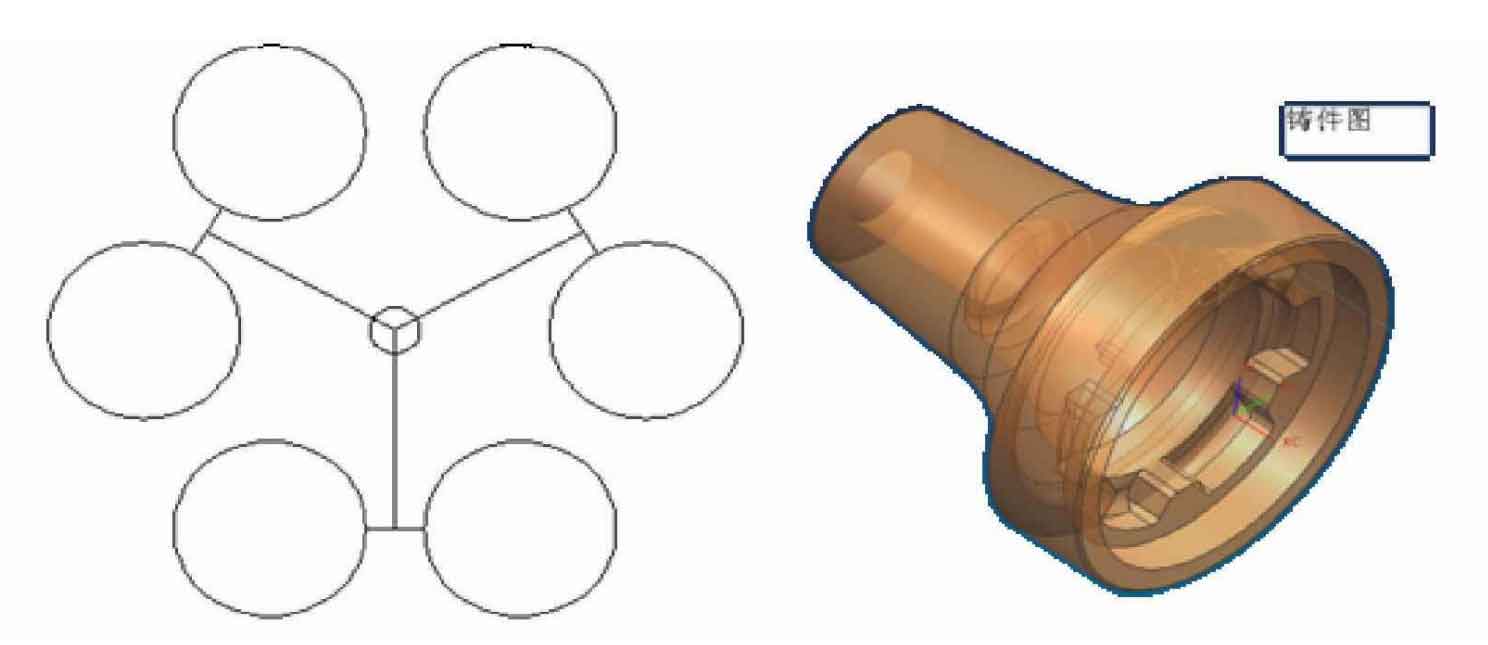

According to the actual production situation, it is determined that the template distribution diagram and the solid diagram of nodular iron castings on the East ninth foundry line are shown in Figure 1:

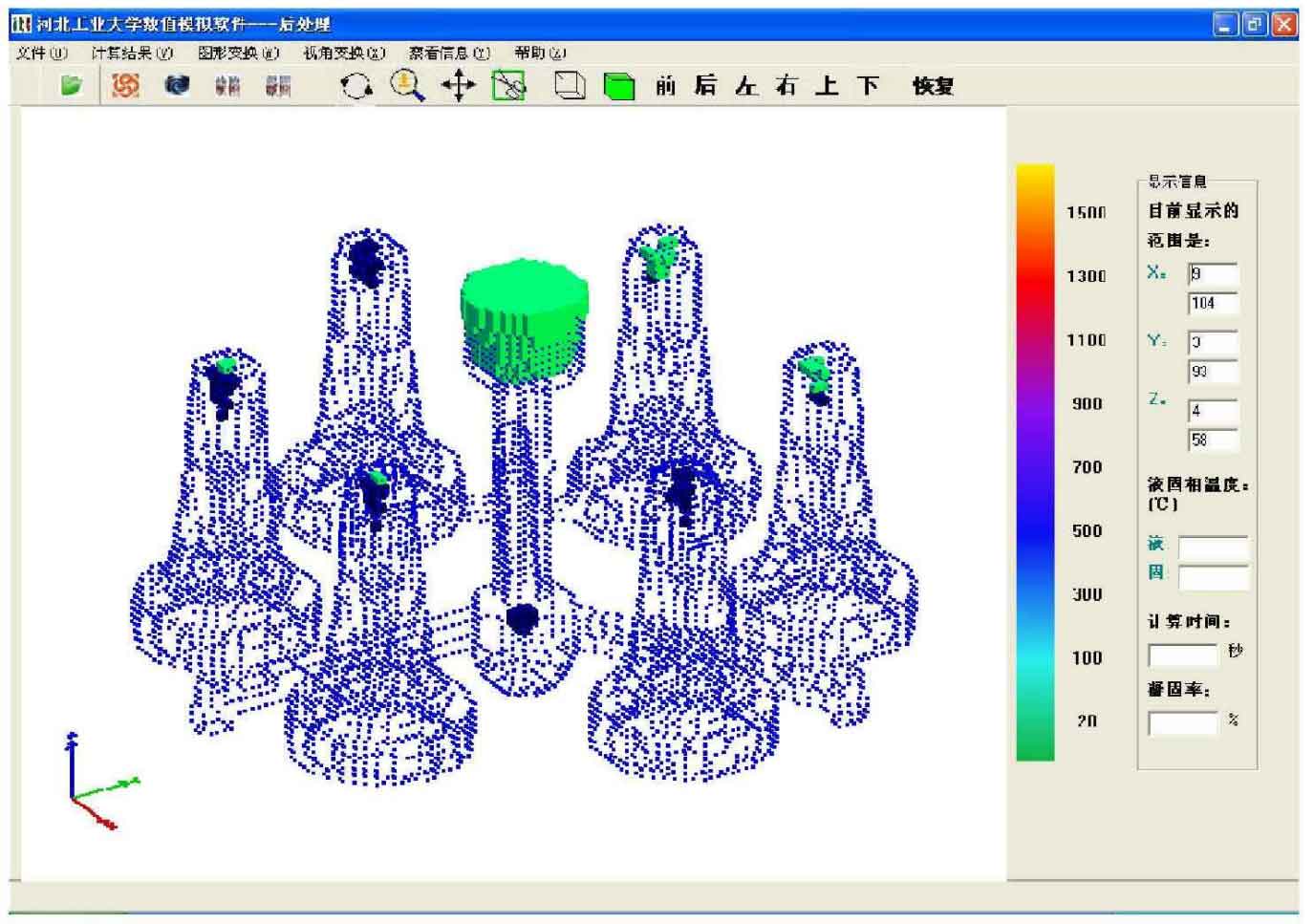

According to the above casting process, after the simulation calculation is carried out on this simulation software, figure 2 is the display diagram of the simulated final shrinkage defects. From the calculation results, it can be seen that the shrinkage porosity and shrinkage cavities are distributed at the top of the riser and the hot spot of the gating system, and the internal casting quality of the nodular iron casting is good. The actual production results have proved that the production of the nodular iron casting can fully meet the requirements. After the actual nodular iron castings are cut by wire cutting, as shown in Figure 3, the internal quality of nodular iron castings is very good and fully meets the requirements.

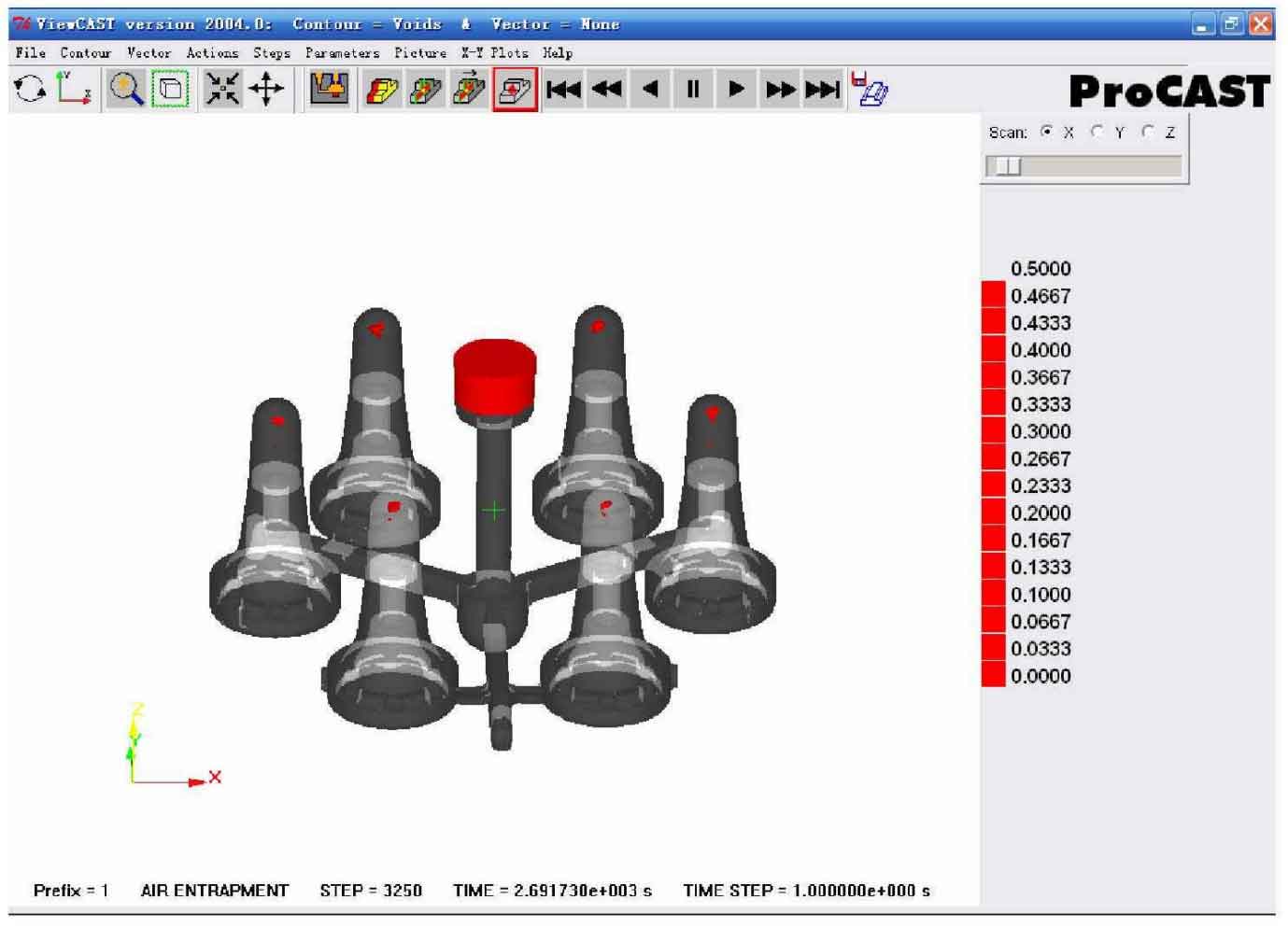

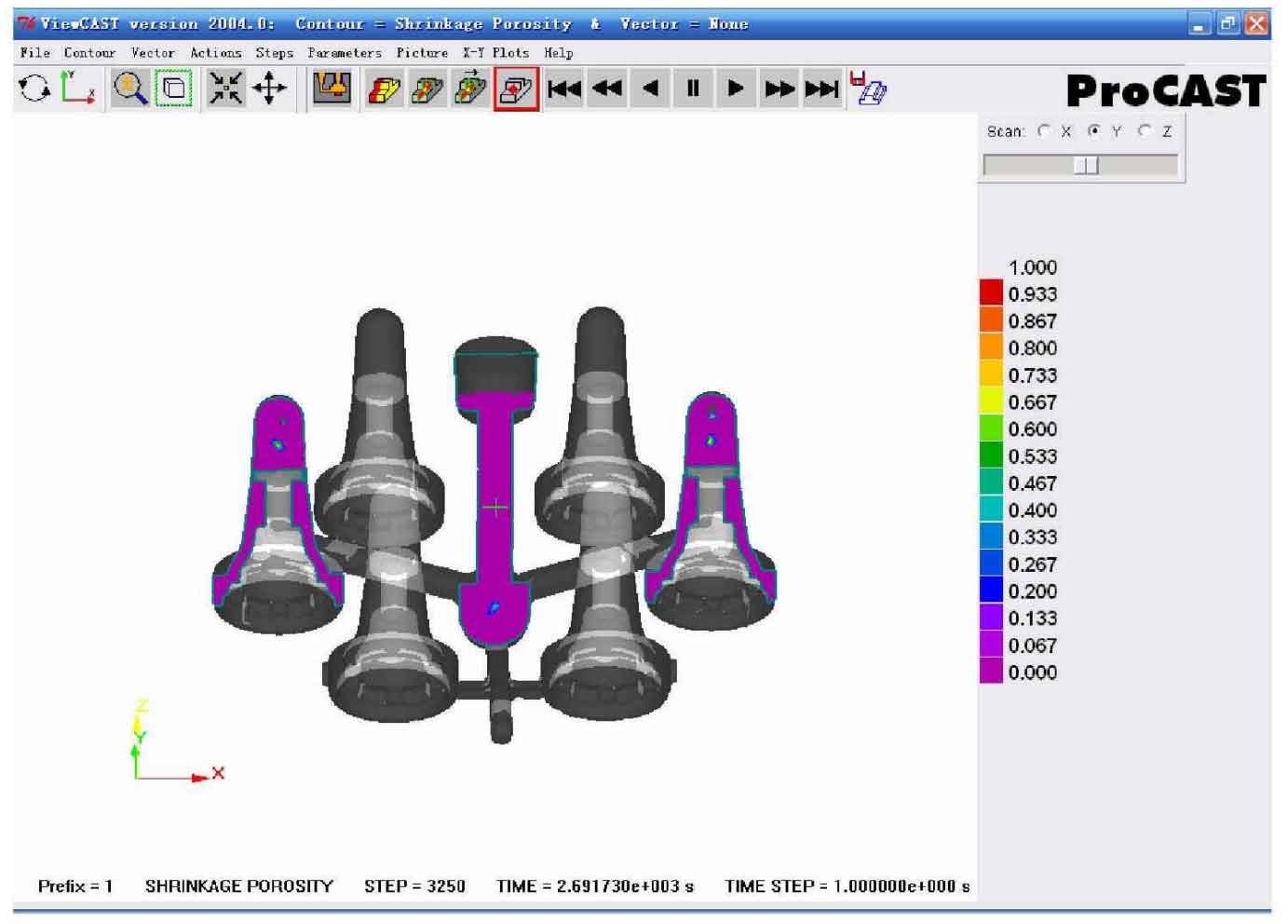

The above ductile iron castings are simulated with the mature commercial simulation software ProCAST under the same material properties, the same production conditions and the same simulation conditions. The simulation results of ProCAST are shown in Figure 4 and figure 5. Figure 4 shows the distribution of shrinkage cavity, and shrinkage defects are distributed on the top of riser and gating system; Figure 5 shows the distribution of shrinkage defects, which are mainly distributed in the middle of the riser and the hot spot of the gating system. From the simulation results, it is completely consistent with the shrinkage defects predicted by this software.