The independent process parameters of sand casting are directly determined by the product drawing and the production process conditions of the enterprise, mainly including the design parameters such as machining allowance and sand casting size. The independent design parameters are the design of the size and structure of sand casting. The independent process parameters of sand casting can most directly reflect the amount of carbon sources of pig iron, scrap steel and other main materials in the process of sand casting, As well as energy carbon sources such as modeling and transportation, and main undesired carbon sources such as sand and waste residue.

1.Carbon emission of materials based on independent process parameters of sand casting

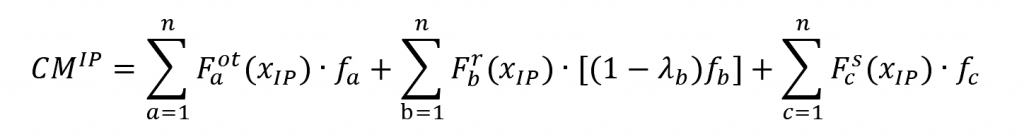

The material carbon source based on the independent process parameters of sand casting includes pig iron, silica sand, steel shot and other main materials, and the carbon emission is calculated as follows:

2.Energy carbon emission based on independent process parameters of sand casting

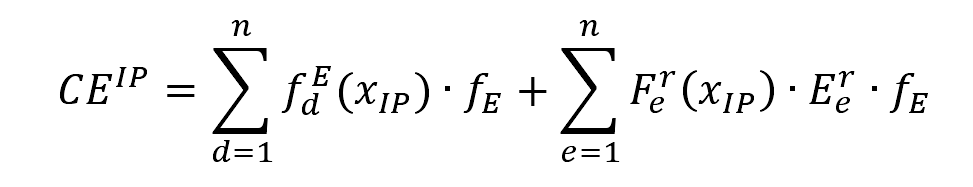

At the same time of material consumption, it is also accompanied by the power consumption of sand casting production equipment. Therefore, the energy consumption accompanied by material consumption is mainly concentrated on the molding, casting, cleaning and other equipment in the process of sand casting. The melting energy consumption of sand casting is comprehensively determined by the amount of molten iron and melting temperature, That is, the casting melting energy consumption is affected by the independent process parameters of sand casting and the coupling process parameters of sand casting such as casting temperature. The carbon emission generated by casting energy consumption cannot be directly determined by the independent process parameters of sand casting. Therefore, the carbon emission of melting energy consumption is not included in the energy carbon emission based on the independent process parameters of sand casting, The energy carbon emission based on the independent process parameters of sand casting is calculated as follows.

3.Unexpected carbon emissions based on independent process parameters of sand casting

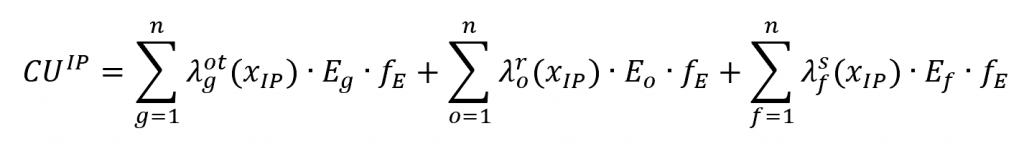

The undesired carbon emission based on the independent process parameters of sand casting takes the undesired substances such as sand ash and waste slag in the process of sand casting as the carbon source, and the undesired carbon sources such as sand ash and waste slag are discharged into the environment after treatment. The undesired carbon source is based on the consumed materials and is affected by the independent process parameters of sand casting, For example, under the fixed recovery process, the ash amount of resin sand is determined by the input amount of resin sand, which converts the power consumption of treating unexpected carbon source into carbon emission. The unexpected carbon emission based on independent process parameters of sand casting is calculated as follows.