The material consumption of sand casting is different from that of other machinery manufacturing industries. The production process of sand casting often involves the recycling of materials, such as the recycling of molding sand and reheating iron. The carbon emission generated by the consumption of such materials is comprehensively determined by the recovery times, recovery rate and energy consumption in the recovery process; At the same time, some materials in sand casting belong to consumable materials, such as steel shot, but the consumption of such materials is in a stable, slow and long-term process. The carbon emission of such consumable materials is converted and shared equally among the process objects in the whole material consumption process. According to the different conversion methods of carbon emission of sand casting materials, the carbon emission of materials in the process of sand casting is divided into one-time material carbon emission, reusable material carbon emission and equally shared material carbon emission.

1.Carbon emission of disposable materials

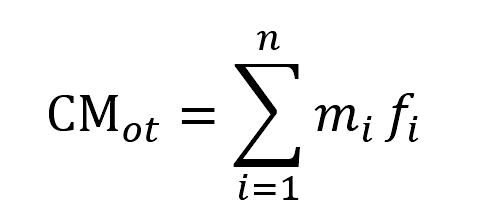

Disposable materials refer to the materials that are directly consumed due to irreversible shape change once input in the sand casting process, including alcohol, coating, pig iron and other materials. The calculation method of carbon emission of disposable materials is as follows:

Where: 𝑚𝑖 represents the consumption of the 𝑖 disposable material and 𝑓𝑖 the carbon coefficient of the 𝑖 disposable material.

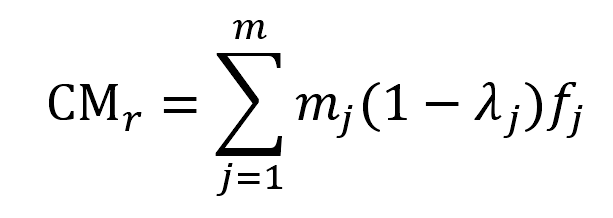

2.Carbon emission of recycled materials

In the sand mold casting process, recycled materials involve additional recovery process. At the same time, the recovery rate of recycled materials is affected by the recovery process, including sand regeneration and remelting of furnace iron. The energy consumed in the recovery process of recycled materials is included in the energy carbon emission and not included in the material carbon emission source. The calculation method of carbon emission of recycled materials is as follows:

Where: CMr is the carbon emission of recycled materials, 𝑚𝑗 is the input of the 𝑗 recycled materials, 𝜆𝑗 is the recovery rate of the 𝑗 recycled materials, and 𝑓𝑗 is the carbon coefficient of power.

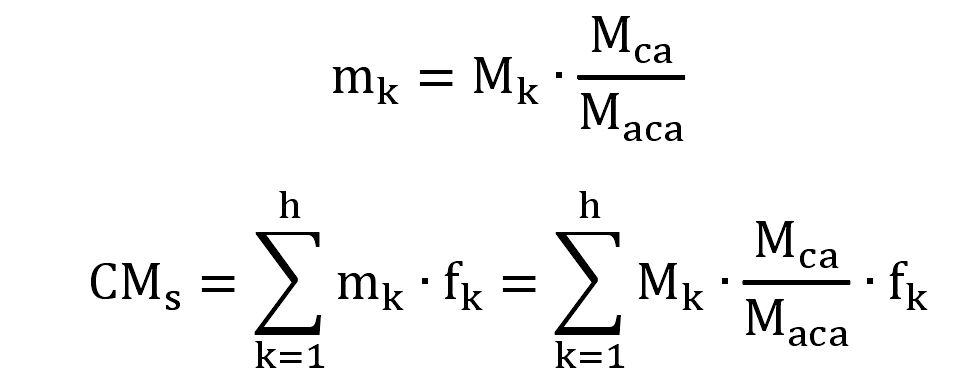

3.Carbon emission of shared materials

The carbon emission of evenly distributed materials refers to the carbon emission generated by such materials in a stable, slow and long-term process of consumption in the process of sand casting, such as steel shot, furnace lining, etc. the carbon emission of such consumed materials is converted to be evenly distributed among all process objects in the whole material consumption process. The calculation method of carbon emission of evenly distributed materials of sand casting is as follows:

Where: 𝑚𝑘 is the consumption of the first kind of evenly distributed material converted to a sand mold casting, Mk is the consumption of the k kind of evenly distributed material in a period of time, M𝑐𝑎 is the quality of a single sand mold casting, M𝑎𝑐𝑎 is the total casting quality during the period of evenly distributed material consumption, and 𝑓𝑘 is the carbon coefficient of the 𝑘 kind of evenly distributed material.