Casting defects are undesired irregularities or imperfections that occur during the casting process. These defects can affect the quality, mechanical properties, and functionality of the castings. Understanding the causes, types, and solutions for casting defects is crucial for improving casting processes. Let’s explore some common casting defects:

- Porosity:

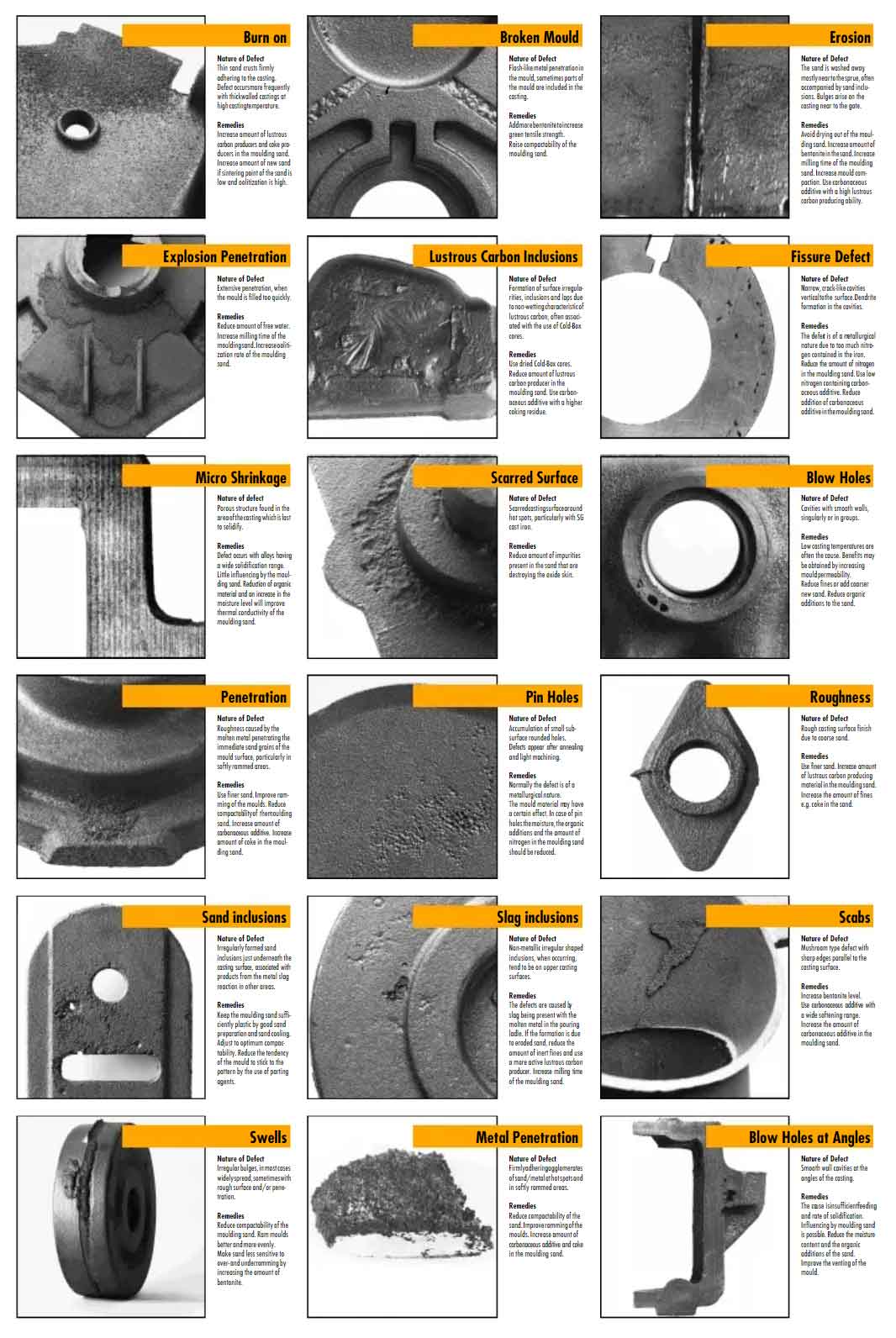

- Cause: Porosity is caused by the entrapment of gas during solidification. Gases can be present in the molten metal or can be generated by reactions with the mold or core materials.

- Types: Porosity can appear as either gas porosity (small bubbles) or shrinkage porosity (larger voids).

- Solutions: Proper degassing techniques, controlling the pouring temperature and rate, using adequate gating and risering systems, and selecting appropriate mold and core materials can help reduce porosity.

- Shrinkage:

- Cause: Shrinkage defects occur due to insufficient feeding of molten metal during solidification, resulting in voids or discontinuities.

- Types: Shrinkage defects can appear as shrinkage cavities, microporosity, or shrinkage cracks.

- Solutions: Designing proper gating and risering systems, ensuring directional solidification, using feeding aids such as risers or chill blocks, and modifying the alloy composition to enhance feeding characteristics can help mitigate shrinkage defects.

- Inclusions:

- Cause: Inclusions are non-metallic or foreign materials that are trapped in the casting during the solidification process.

- Types: Inclusions can be in the form of sand, oxides, slag, or other contaminants.

- Solutions: Using high-quality and properly prepared molding materials, controlling the melting and refining processes, employing effective filtration systems, and ensuring proper pouring practices can minimize inclusion defects.

- Cold Shut:

- Cause: Cold shut defects occur when two streams of molten metal do not fuse properly during casting, resulting in a visible line or crack.

- Solutions: Proper design of gating and risering systems, controlling the pouring temperature and rate, and ensuring proper mold filling techniques can prevent cold shut defects.

- Misruns:

- Cause: Misruns occur when the molten metal does not completely fill the mold cavity, resulting in an incomplete casting.

- Solutions: Optimizing the mold design, ensuring proper gating and risering systems, improving the fluidity of the molten metal, and controlling the pouring temperature and rate can help prevent misruns.

- Hot Tears:

- Cause: Hot tears or hot cracking defects occur due to localized shrinkage and tensile stresses during solidification and cooling.

- Solutions: Proper design of the casting geometry, use of suitable mold materials with good thermal properties, and applying appropriate cooling techniques can reduce the occurrence of hot tears.

To address casting defects, several techniques and practices can be employed, including:

- Process optimization through computer simulations and modeling.

- Quality control measures such as inspection and non-destructive testing.

- Monitoring and controlling process parameters like temperature, mold quality, and pouring techniques.

- Continuous improvement through feedback and analysis of defect data.

By understanding the causes and types of casting defects and implementing appropriate solutions, manufacturers can improve the quality, integrity, and reliability of castings, resulting in higher performance and customer satisfaction.