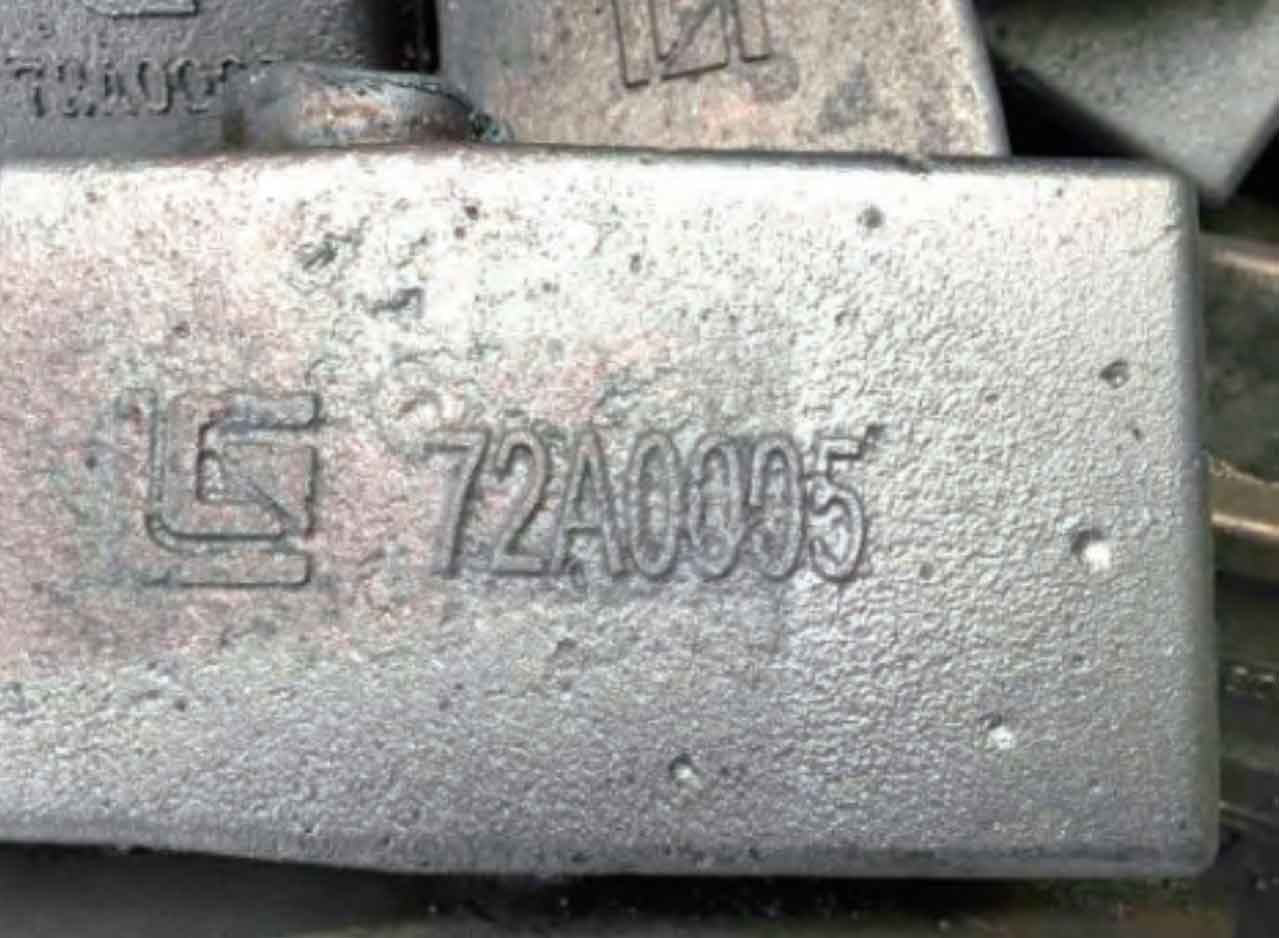

The molten steel contains gas in the melting process, which requires pre deoxidation and final deoxidation. If the deoxidation is not sufficient, it is easy to form pores (as shown in the figure). Such pores are small in volume, generally less than 3 mm in diameter, and are randomly distributed throughout the casting.

Preventive measures:

a) In the smelting process, strictly control the gas content of molten metal, ensure that the raw materials used meet the requirements, standardize the smelting operation, and select appropriate smelting equipment.

b) Before tapping, aluminum ingot shall be used for deoxidation treatment, and oxygen content in molten steel shall be measured by oxygen determinator to make oxygen content in molten steel < 15 × 10-6%。 The molten steel after deoxidization with aluminum shall not stay for too long, and shall be cast within 2 ~ 3min.