The common Pouring Scheme of pouring riser refers to the selection of three cylindrical thermal insulation open risers, which are evenly placed on the upper end of gear blank steel castings. The included angle between risers is 120 °, and any one of them is selected as the gate at the same time. It is basically the same as the calculation steps. Round the results by modulus method and consult the sand casting manual to determine the riser size as riser diameter d = 30mm; Riser height h = 45mm; Single riser volume VR1 = 0.03186l. The riser insulation sleeve with the same composition as the central top pouring scheme shall be used. Wall thickness of insulation sleeve δ = 7mm。 According to the formula, the three risers can feed 0.043l of molten metal at most. Volume of sand castings requiring feeding vs = 0.03l. Therefore, the riser can fully meet the feeding needs of gear blank steel castings.

The total mass of the pouring scheme M= ρ (Vc+3VR)=4.675kg。 The relative density of sand castings is obtained by substituting the formula ρ 0=3.65kg/dm3。 According to the table, the pouring time coefficient C = 1.1 is substituted into the formula to determine that the pouring time of the pouring scheme is 2.374s.

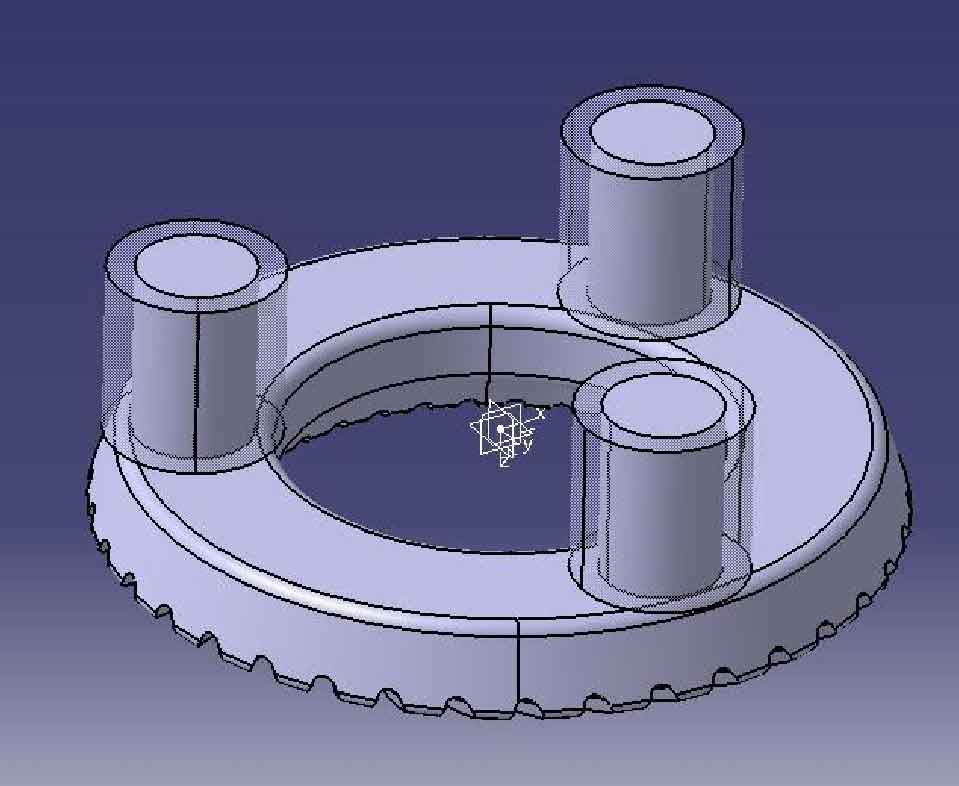

The three-dimensional digital model is established through CATIA to obtain the sand mold casting process diagram, as shown in the figure.