1. Casting characteristics

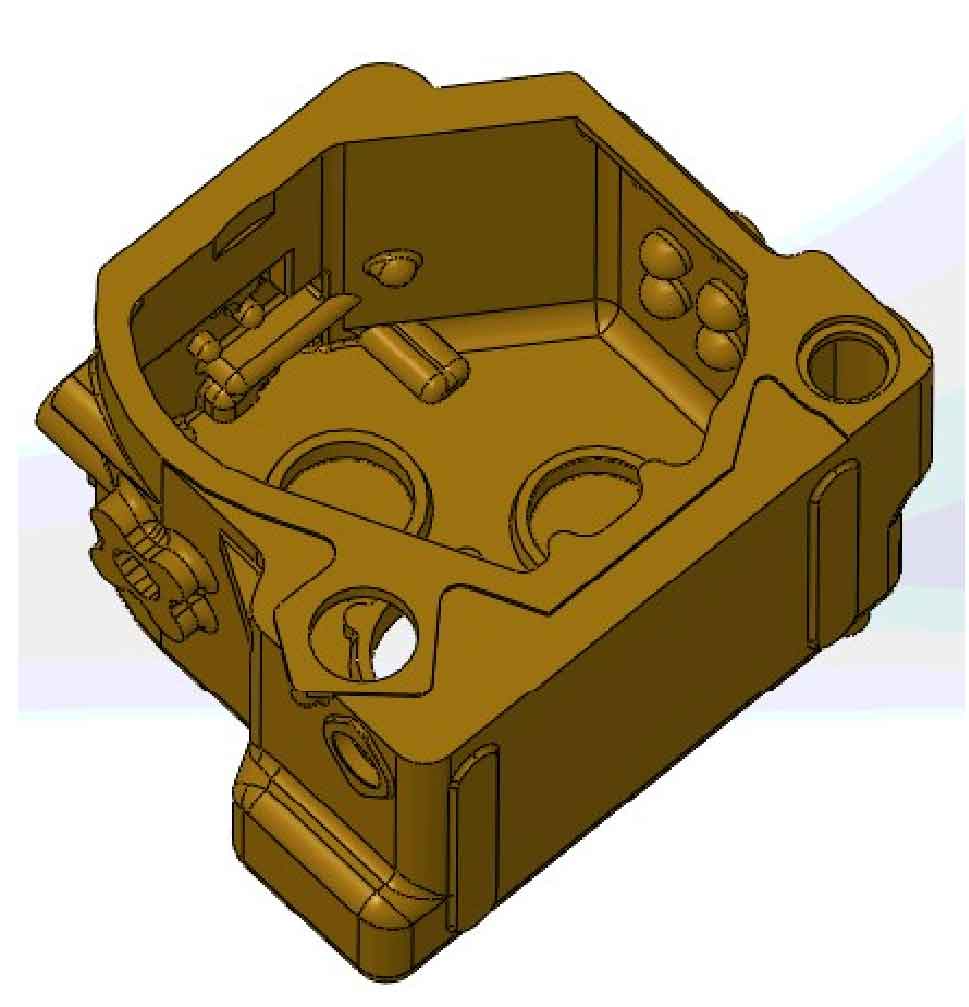

As shown in Figure 1, the overall dimension of the box is 560mm × 480 mm × 420 mm, weighing about 85 kg. The material of the box is HT250, and the chemical composition of HT250 gray cast iron is shown in the table.

It can be seen from the figure that the shape of the sand casting of the gearbox box is not regular. The bottom and lower sides are relatively thick, the wall thickness around the box is relatively thin, the inner cavity is relatively large, and the internal shape is also complex. Generally speaking, the wall thickness difference is large and uneven. The maximum wall thickness is the bottom of the box, the size is 75mm, and the minimum wall thickness is located at the upper part of the box, and the size is only 8mm. There are many characteristics of upper surface, transition fillet, hole and boss in box sand casting. The surface of sand casting is required to be free of slag inclusion, pore and other defects; At the same time, it is required that the shrinkage porosity and shrinkage cavity defects in the thick part of the box are small, the shrinkage porosity and shrinkage cavity in the thin wall around the sand casting of the box are less, and the organization inside the whole box is required to be dense.

| C | Si | Mn | P | S | Other |

| 3.1-3.4 | 1.6-1.9 | 0.8-1.0 | ≤0.15 | ≤0.12 | ≤0.02 |

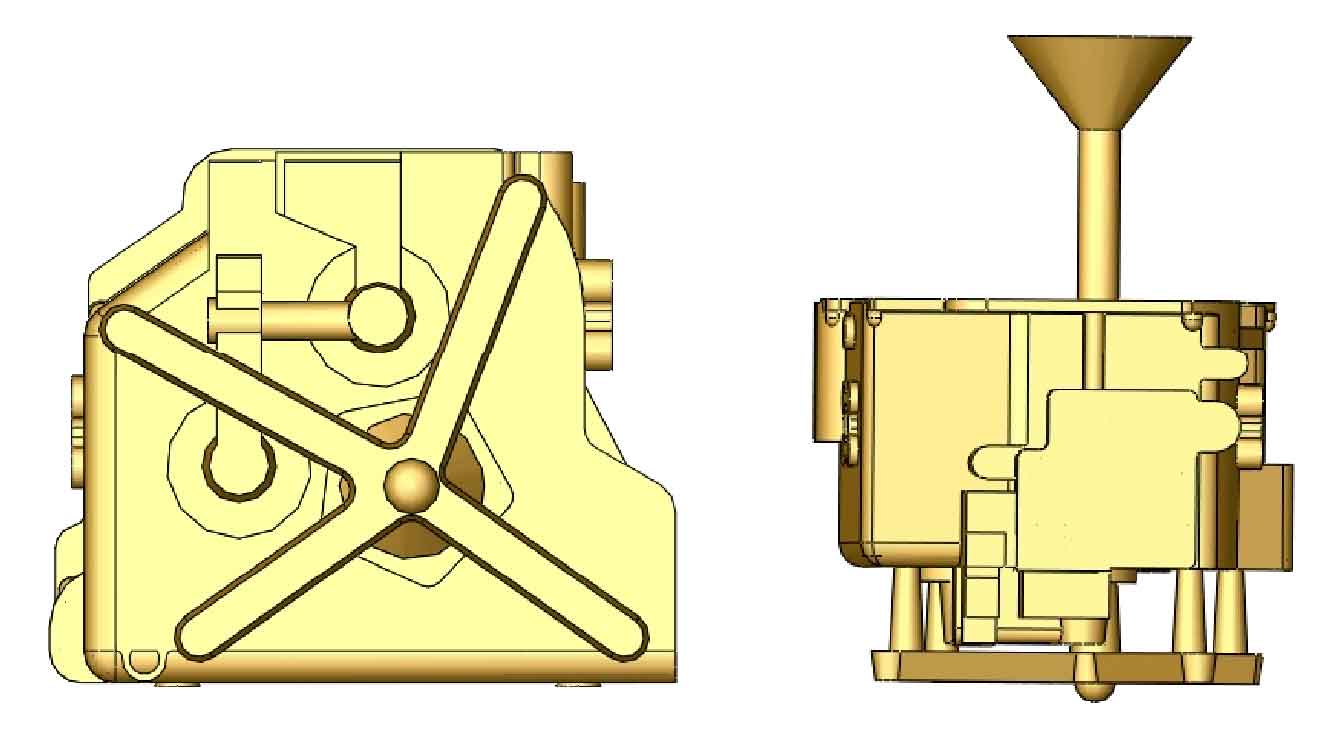

2. Original process gating system

It can be seen from the figure that the liquid metal of this gating system flows from the bottom of the sand casting, and the four ingates are evenly distributed at the bottom of the box. This gating system is called bottom pouring gating system. The advantage of adopting this gating system is that the liquid metal flows smoothly into the mold cavity of sand casting from the bottom of the box. Since it flows in from the bottom, the impact force is small, and the oxidation of metal is small. The liquid metal flows in from the bottom, and the gas in the mold cavity of sand casting is easy to be discharged. Due to the high temperature at the lower part of the sand casting, it is not conducive to feeding, and there is a lot of metal liquid consumption. If the mold filling time is too long, the metal liquid will contact with the air for a long time during the rise of the mold cavity, and the oxide skin is easy to form on the surface; However, this is favorable for the discharge of the gas mixed in the flow process of liquid metal and the gas brought by the gating system itself. Therefore, it is more suitable for sand castings made of non-ferrous alloy and cast steel, and for sand castings with complex shape or high three-dimensional shape. The gating system of the original process is shown in Figure 2. There are 4 internal sprues with circular cross section, d = 30mm; 4 cross runners, with trapezoidal cross section, 35mm upper bottom, 44mm lower bottom and 35mm high; 1 sprue, with circular cross section, d = 50mm, and sand box size of φ eight hundred × 1000mm。