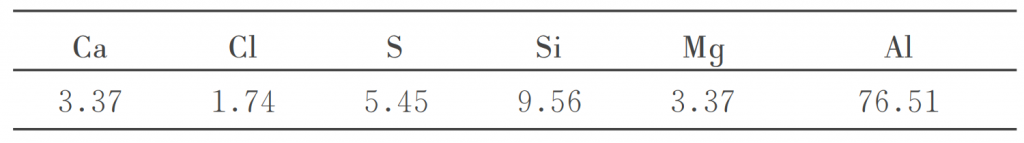

1. Chemical composition of corrosion products on the surface of cast parts

In order to prevent other foreign impurities from mixing in the test process, avoid collecting surface corrosion products with iron tools during sampling, directly use conductive adhesive to take the corrosion products on the surface of cast parts, and place them under scanning electron microscope for chemical composition energy spectrum analysis. The average composition of the analysis results is shown in Table 1.

It can be seen from table 1 that the corrosion products on the surface of cast parts contain Ca, Cl, s, Si, Mg, Al and other elements. The content of harmful elements such as s, Si, Ca and Cl is relatively high, while the content of main elements Al and mg of the alloy is relatively low (compared with the standard of AlMg10 alloy).

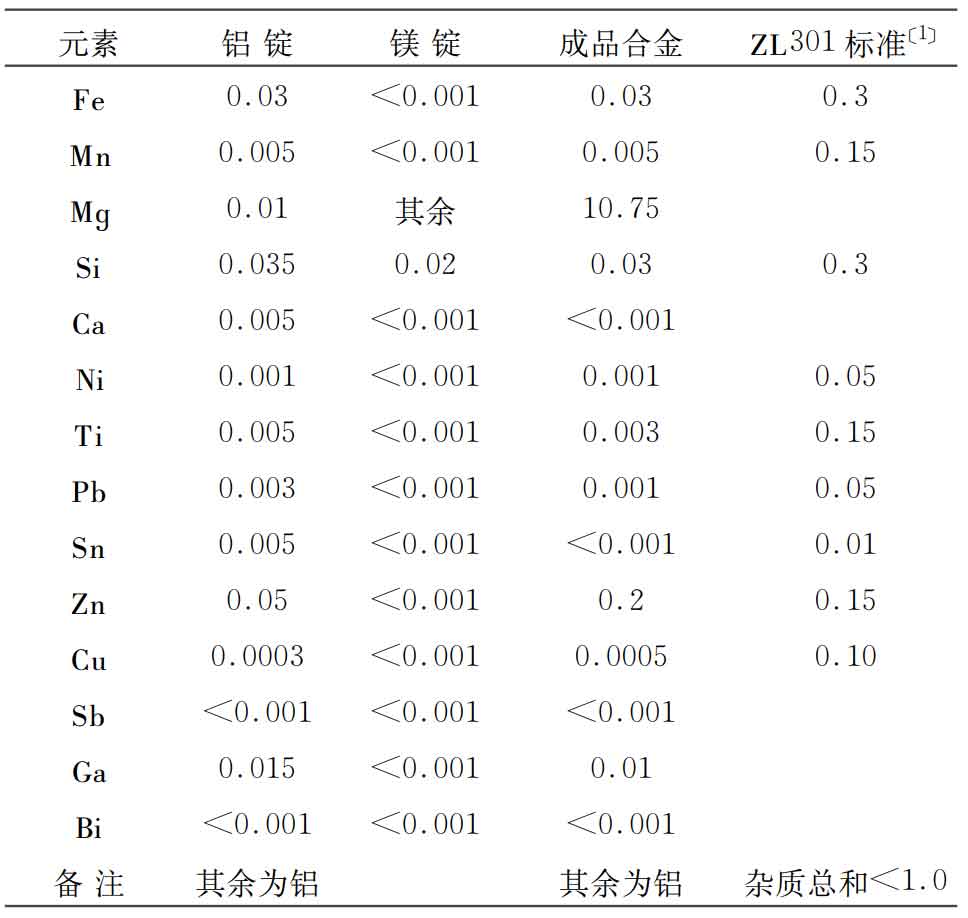

2. Chemical composition spectrum and chemical analysis of aluminum ingots, magnesium ingots and finished products

Considering the possible non-uniformity of the composition of each part of the sample of casting parts, in order to accurately determine the overall composition, the method of multi-point drilling cuttings at different parts of the sample is adopted to conduct spectral and chemical analysis on the raw material aluminum ingot, magnesium ingot and test bar samples respectively. The comprehensive analysis results are shown in Table 2.

Table 2 shows that the impurity content of aluminum ingot and magnesium ingot is relatively low, and the purity of magnesium ingot is more than 99 ∙ 999%. The content of impurity elements in the overall composition of Al Mg alloy test bar is lower than the national standard; The content of alloy element Zn is 0 ∙ 2%, which is slightly higher than the national standard of 0 ∙ 15%. Considering that the distribution of microstructure and composition of cast parts has a certain dispersion, it can be considered that the content of Zn also basically meets the national standard. Therefore, it can be considered that the overall composition of the analyzed samples basically meets the standard requirements. According to the manufacturer’s reaction, the mechanical properties of the test bar are acceptable, which is consistent with the overall composition basically meeting the requirements.