The pouring system of tractor box castings can be divided into closed type, open type, semi closed type and closed open type according to the sectional area of each component. In the closed system, A cup > A straight > A horizontal > A inside. In this way, the liquid metal is easy to fill the mold cavity, and the flow rate of liquid metal is fast. It is suitable for iron castings. The metal liquid in the open system is not easy to fill the pouring system and casting cavity of tractor box castings, and the metal liquid is not filled. The casting is a thin-walled casting, which has a large plane and is not easy to fill the cavity. Therefore, the flow speed of liquid metal is fast, so the closed system is adopted.

According to the position of the inner gate on the casting, the gating system of tractor box castings can be divided into bottom injection type, middle injection type, top injection type and stepped type.

(1) Bottom injection

The inner sprue of the bottom injection gating system of tractor box castings is placed at the bottom of the casting, and the metal liquid flows smoothly into the mold cavity, and the impact on the mold cavity and sand core is small, which is conducive to the discharge of gas. However, long-term mold filling will cause the metal liquid to contact with air and generate oxide skin, so this method is not used in this paper.

(2) Middle note type

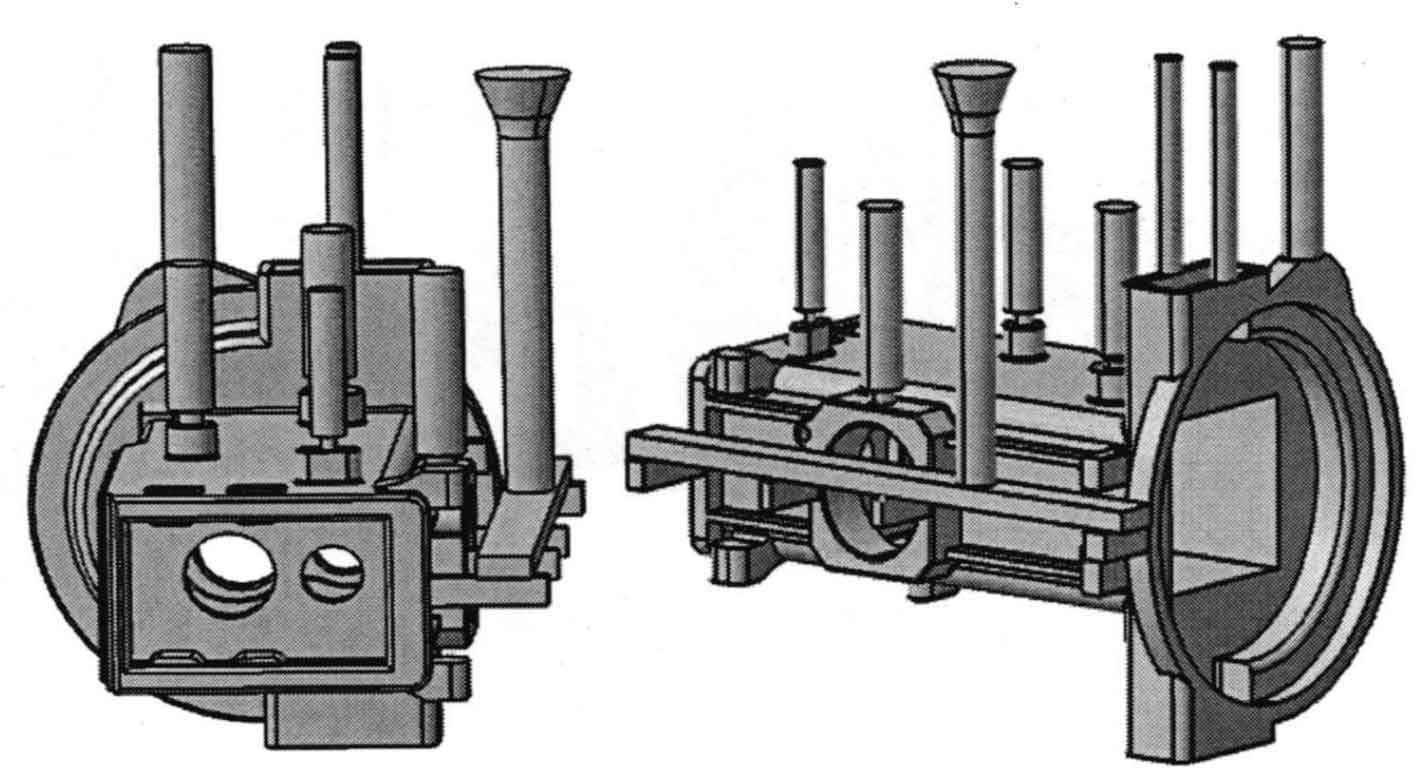

The inner sprue of the mid injection gating system of tractor box castings is placed at a certain position in the middle of the casting, which generally makes the metal liquid injected from the parting surface, and the modeling is relatively simple. In this way, the casting process scheme I is designed. The inner sprue is located in front of the box, and the number of inner sprues is temporarily set to four. A riser is added above the rectangular boss at the lower end of the reducer box, an air outlet is added on the circular boss at the lower end, and a riser is designed on the boss at the side. The design of the injection pouring system in scheme I is shown in Figure 1.

(3) Top injection

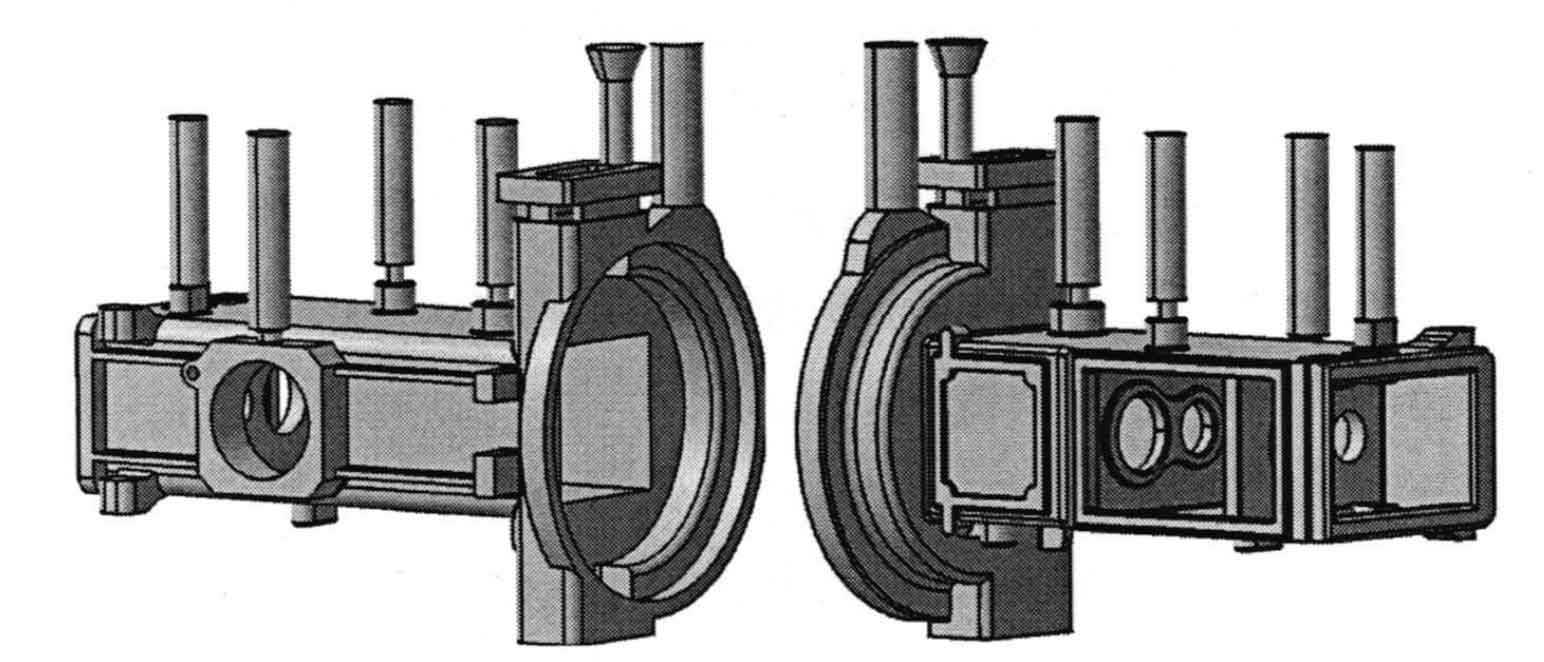

The top pouring sprue of tractor box casting is set at the top of the casting, and the metal liquid enters the mold cavity from the top, so the mold is easy to fill; The deluge type is that the metal liquid flows into the mold cavity from multiple top holes, which has the characteristics of low impact on the mold wall, which is conducive to the bottom-up solidification sequence and good feeding conditions of tractor box castings. In this paper, the pouring scheme II is designed in this way. The inner sprue is located on the rectangular boss of the lower base of the box. The inner sprue is distributed in a rectangular shape, and a riser is set on the side boss and the circular boss of the lower base. The top injection process scheme of scheme II is shown in Fig. 2.

(4) Layered injection (stepped)

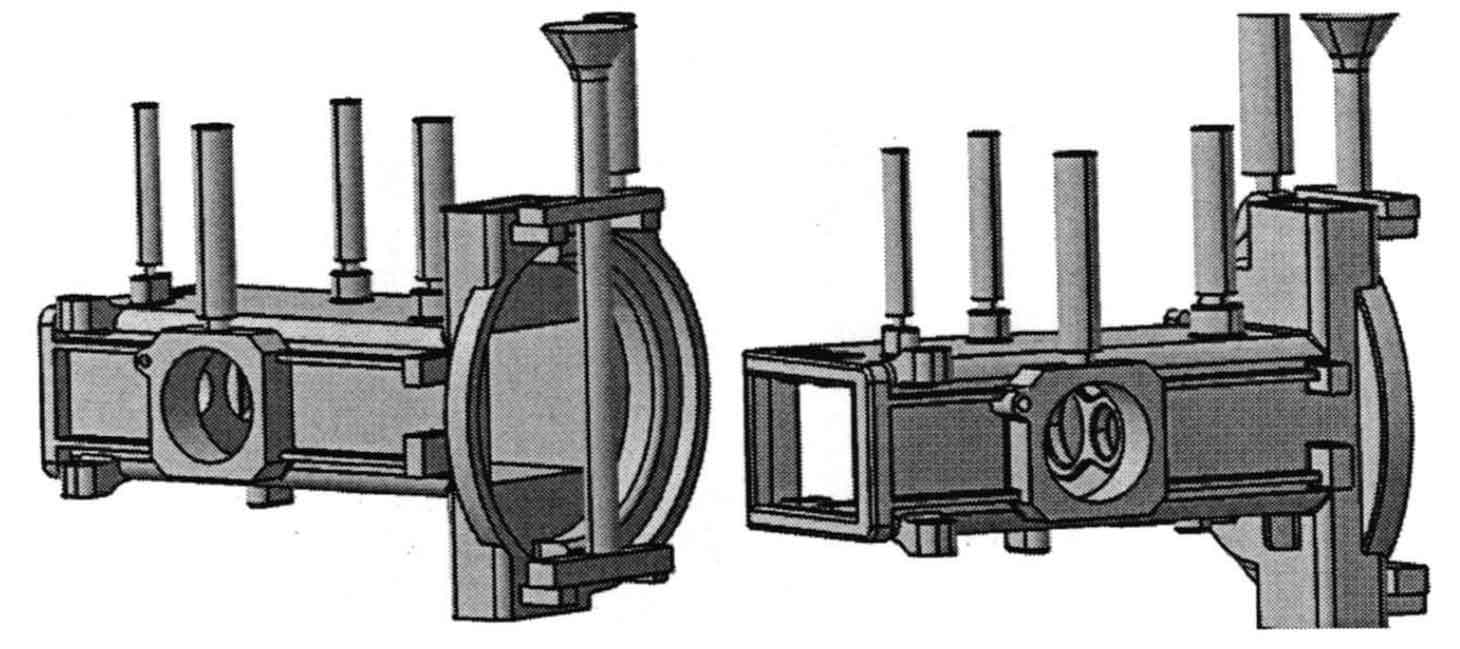

The step type is that when the liquid metal enters the cavity, it flows into the cavity layer by layer from top to bottom. The inner sprue is dispersed, the impact force of the liquid metal is small, and the filling is relatively stable. This paper adopts this method to design the pouring scheme 3. The inner sprue is divided into two layers. The inner sprue is located on the end face of the base at the lower end of the box, an air outlet is added on the circular boss of the base, and a riser is designed on the boss on the side. The process scheme of the step type pouring system of scheme 3 is shown in Figure 3.