According to the different forms of centrifugal casting, it can be classified. According to the application of centrifugal force, the classification method was first put forward by the United States and Germany, and the corresponding concept was also stipulated in GB / t5611-1998 foundry terminology in China. It is called true centrifugal casting to make liquid metal cling to mold wall and form cavity casting by centrifugal force generated by rotation without sand core. Cast pipe and cylinder liner are typical products of true centrifugal casting. In centrifugal casting, the rotation axis can be at any angle, such as the horizontal rotation axis for long parts such as pipes, and the vertical rotation axis for short parts such as cylinder liners and shaft sleeves. The mold shape of semi true centrifugal casting is also axisymmetric, but its structure is much more complex than that of pipes and cylinder liners. The center hole of the casting can be made with sand core, and the rotational speed of the mold is much lower than that of true centrifugal casting. In semi true centrifugal casting, centrifugal force is helpful to mold filling and solidification, but not to forming. The shape of the parts in non true centrifugal casting is not limited. Only the centrifugal force is used to increase the solidification pressure of liquid metal, the mold rotation speed is lower, and the casting center line does not coincide with the rotation axis.

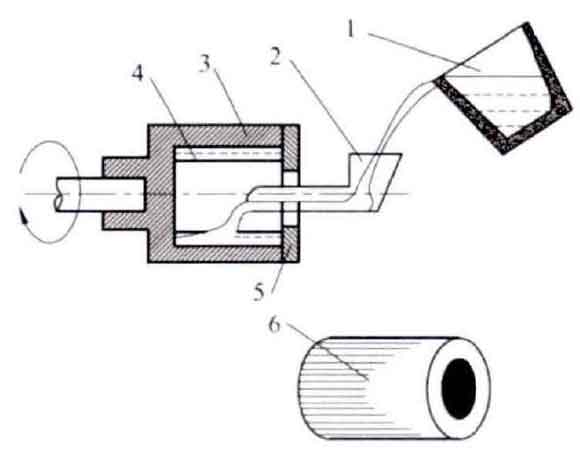

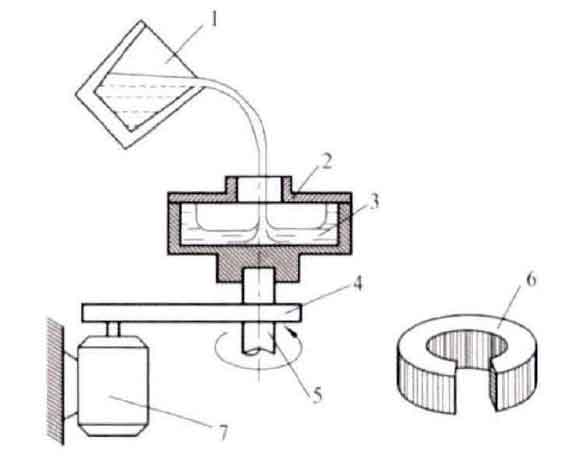

The classification method commonly used in China is based on the position of rotation axis, because it is the same as the classification principle of centrifugal casting machine, that is, it is divided into horizontal (or horizontal) centrifugal casting machine (Fig. 1, 2) and vertical centrifugal casting machine (Fig. 3, 4). The corresponding centrifugal casting machine is called horizontal (or horizontal) centrifugal casting machine and vertical centrifugal casting machine. Vertical centrifugal casting is mainly used to manufacture Ring Castings and small non-circular castings with compactness requirements, as well as parts that are difficult to be produced by static casting due to various reasons, such as gears, piston rings, impellers, propellers, shaft sleeves and train wheels; horizontal centrifugal casting is mainly used to manufacture hollow castings with large length, such as various pipes, sleeves, connecting rods, etc The minimum diameter of cast tubular parts is 40mm and the maximum diameter is 8000mm.

Centrifugal casting mold can be made of different materials, according to its classification: metal mold, metal mold with refractory layer (such as sand lining or spray coating), sand mold and mold made of gypsum, graphite and other materials can be used in centrifugal casting process. The first two kinds of molds are used in the true centrifugal casting, especially in the horizontal centrifugal casting. Because of the large quantity and large size of casting, the metal mold with long service life is required. The latter two molds are mostly used in vertical centrifugal casting to cast some small-size castings.

In centrifugal casting, the metal mold can work at different temperatures. In order to improve productivity and accelerate casting solidification, the metal mold is often sealed in a water jacket and cooled by cooling water, so that the metal mold body is at a lower temperature in the working process, so it is called water-cooled metal mold or cold mold centrifugal casting. If the mold is cooled by air (static or flowing) or a small amount of water spray during continuous operation, and the metal mold works at a higher temperature, it is called hot mold centrifugal casting. In fact, cold mold and hot mold are also relative: when cold mold method is used, the temperature of metal mold body fluctuates between 40-250 ° C, and the inner wall temperature also reaches 650-700 ° C during casting, which can quickly drop to the predetermined temperature of the body due to rapid continuous cooling; when hot mold method is used, the temperature of metal mold fluctuates between 350-450 ° C, but the inner wall temperature is not high enough The temperature difference between the inner wall and the outer wall is smaller than that of the cold mold method.

Different centrifugal casting methods have different scope of use, and the horizontal centrifugal casting, which is the real centrifugal casting, is the research object of this paper.