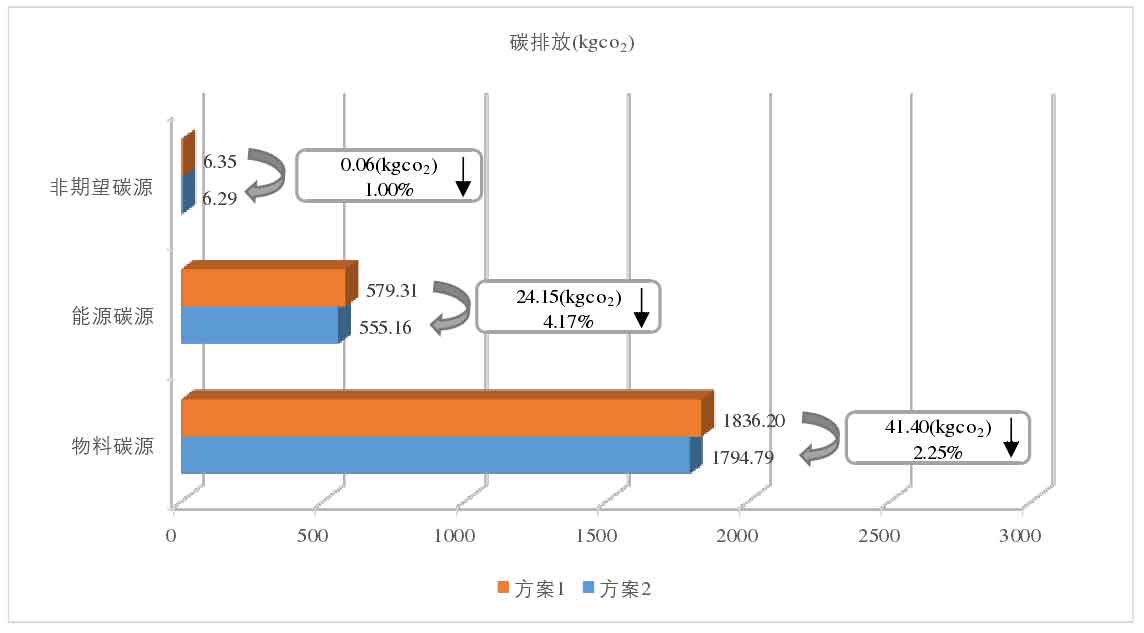

The carbon emissions of the two schemes before and after optimization are calculated respectively. By comparing the carbon emission of two sand casting process design schemes, the effectiveness of the calculation method and optimization method of carbon emission of sand casting based on process parameters is verified. Compared with scheme 1, scheme 2 changes four process parameters: draft angle, fillet radius, machining allowance and pouring temperature. The carbon emission comparison results of the three carbon sources are shown in Figure 1. It can be found that the carbon emissions of energy carbon sources are the largest among the three carbon sources.

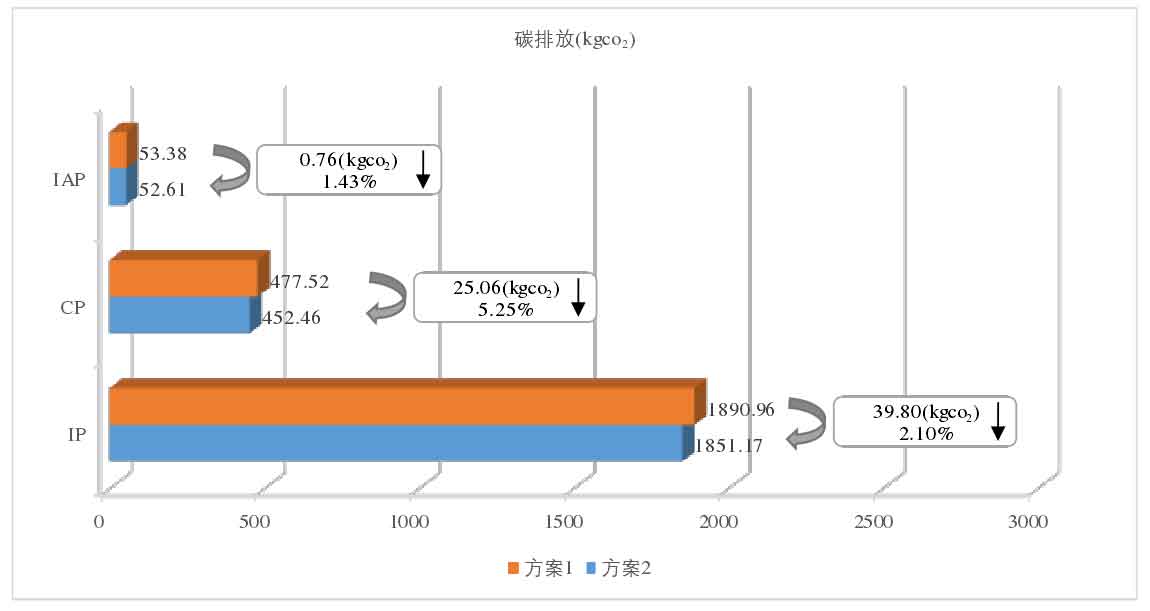

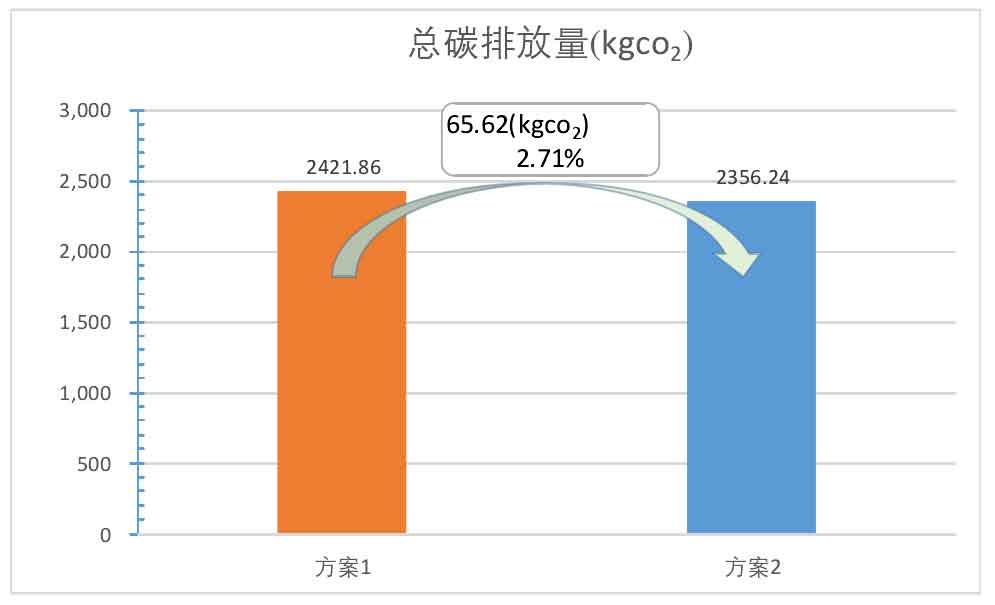

The carbon emissions of energy carbon sources decreased by 4.17% from scheme 1 to scheme 2. Through the analysis of the previous calculation process, it can be judged that the main reason is the decrease of pouring temperature, which leads to the decrease of energy carbon emission. The carbon emission of material carbon source was the largest, but the carbon emission of material carbon source decreased by only 2.25%. The reduction of undesired carbon source is very small, only 1.00%. However, due to the great harm of undesired carbon emission to the environment, the research on undesired carbon emission is of great significance to realize green casting. Figure 2 shows the carbon emissions calculated using different sand casting process parameters in the two schemes. Compared with the data in the figure, the carbon emission under CP decreased by 5.25%, which is the one with the largest reduction in carbon emission among the process parameters of sand casting. The carbon emission under IP has decreased by 39.80kg, and the reduction of carbon emission is also considerable. Figure 3 shows the comparison results of the total carbon emissions of the two schemes. Compared with scheme 1, scheme 2 reduces the carbon emissions by 2.71%. In other words, the annual total carbon emission of sand casting enterprises with an annual output of 40000 tons can be reduced by 1084 tons.

Through the calculation of carbon emission in the process design stage of sand casting, the composition of carbon emission is analyzed. Comparing the carbon source composition of the two schemes, it is not difficult to find that the reduction of carbon emission of CP carbon source is caused by the reduction of carbon emission of energy carbon source. The carbon emission under CP mainly comes from the power consumption in the process of iron melting. The smelting carbon emissions calculated by the two schemes account for 72.94% and 71.82% of the energy carbon emissions respectively, which is very close to the reference statistical data. The temperature control of smelting furnace in sand casting enterprise is the key factor to reduce carbon emission. In addition, the largest proportion of carbon emission in the total carbon emission of sand casting is the material carbon source. The carbon emission of material carbon source is mainly estimated through IP, and the material carbon source is composed of various materials. Improving the sand casting process chart can effectively reduce the carbon emission of material carbon source. The carbon emissions of undesired carbon sources are mainly determined by IAP. Choosing environmentally friendly materials can reduce carbon emissions from undesired carbon sources. The premise of calculating carbon emission by this method is to ensure the quality of sand castings.

The results show that the carbon emission of sand mold can be significantly reduced by using genetic algorithm. This method can effectively reduce the carbon emission of sand castings in the process design stage. Domestic reports pointed out that by 2020, China’s energy consumption and carbon dioxide emissions per unit of GDP should be reduced by 15% respectively

And 18%. As one of the main energy consumption sources and waste emission sources in the world, sand casting industry plays an important role in realizing the national goal of energy conservation and emission reduction. Method is a promising method to help sand casting enterprises achieve this goal, which can support designers to create low-carbon sand casting process in the planning stage, because this method can significantly reduce the carbon emission of materials by adjusting the draft angle, fillet radius and machining allowance.