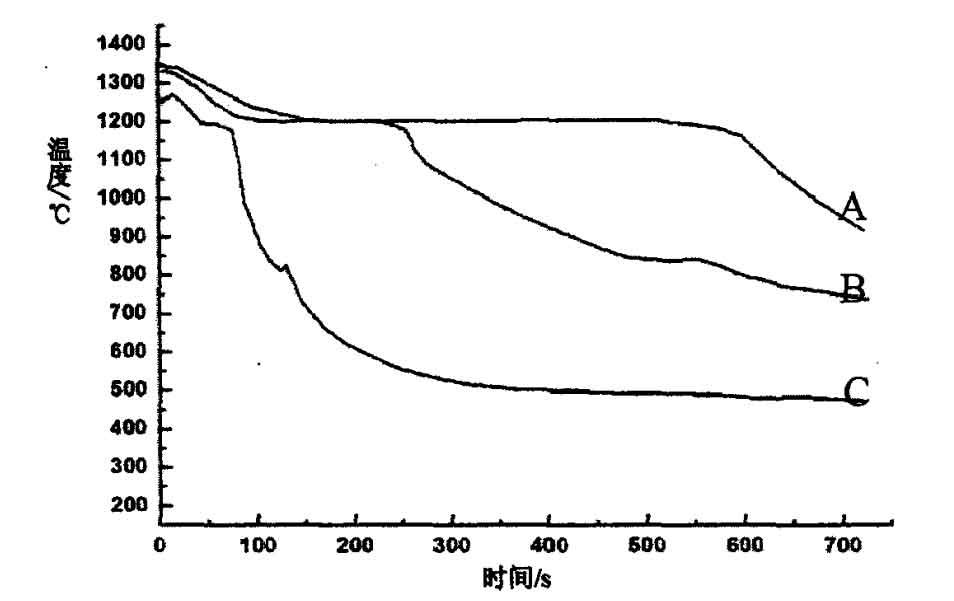

Comparing the cooling curves of sand mold, iron mold sand coated casting and metal mold casting, it can be seen from the figure that the cooling rate of iron mold sand coated casting is three times that of sand mold, but far lower than that of metal mold, so it can not only effectively protect the iron mold, but also improve the mechanical properties of castings, Therefore, using iron mold sand coating process to prepare high melting point alloy is a more economical process scheme.

Compared with the three processes of sand casting and metal casting, it can be seen that using iron mold sand coated casting to produce crankshaft has the following advantages:

(1) The mold has high hardness, easy self feeding, reduced shrinkage porosity and compact structure;

(2) The cooling speed of liquid metal is fast, the grain of casting is fine, the content of pearlite in matrix increases, and the performance of casting is improved;

(3) The riser free casting process is realized, with high dimensional and shape accuracy, small machining allowance and improved yield;

(4) It is suitable for mass production, with high productivity, small amount of coated sand, reduced workshop pollution and high economic benefits.