Casting shrinkage refers to the shrinkage of the solidification and cooling process of liquid metal, which causes the dimensions of various parts of the steel casting to be smaller than the original dimensions of the pattern. Therefore, in order to make the cooled size of the steel casting consistent with the size shown in the drawing, it is necessary to add its shrinkage size to the pattern or core box.

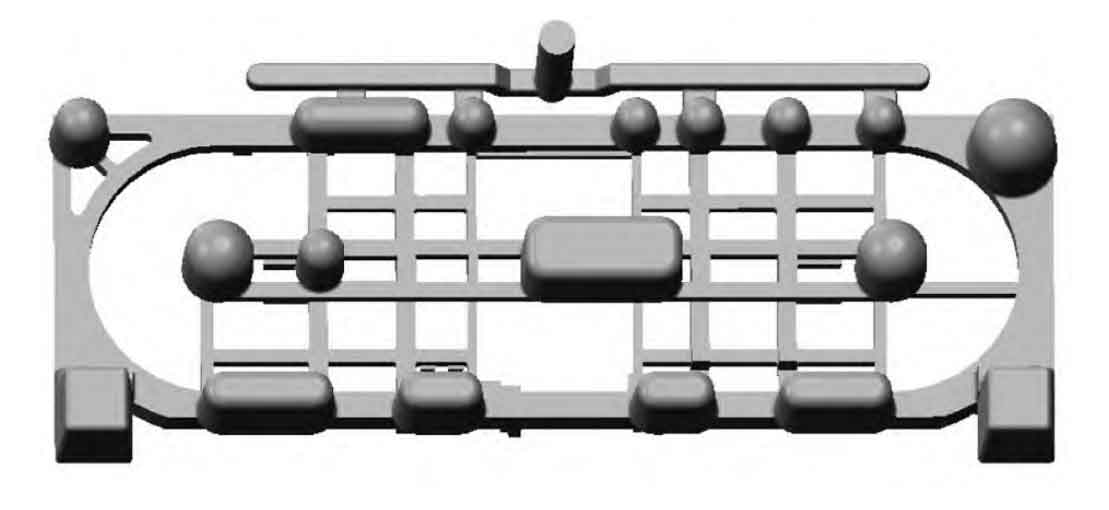

Considering the complex structure of the steel casting, improper shrinkage setting of the steel casting can lead to scrap of the steel casting (mold), and it is necessary to explore its restrained shrinkage state through certain experiments. When designing the process, taking into account the different shrinkage of various parts of the steel casting, different casting shrinkage rates are adopted to ensure that the size of the steel casting meets the drawing requirements.

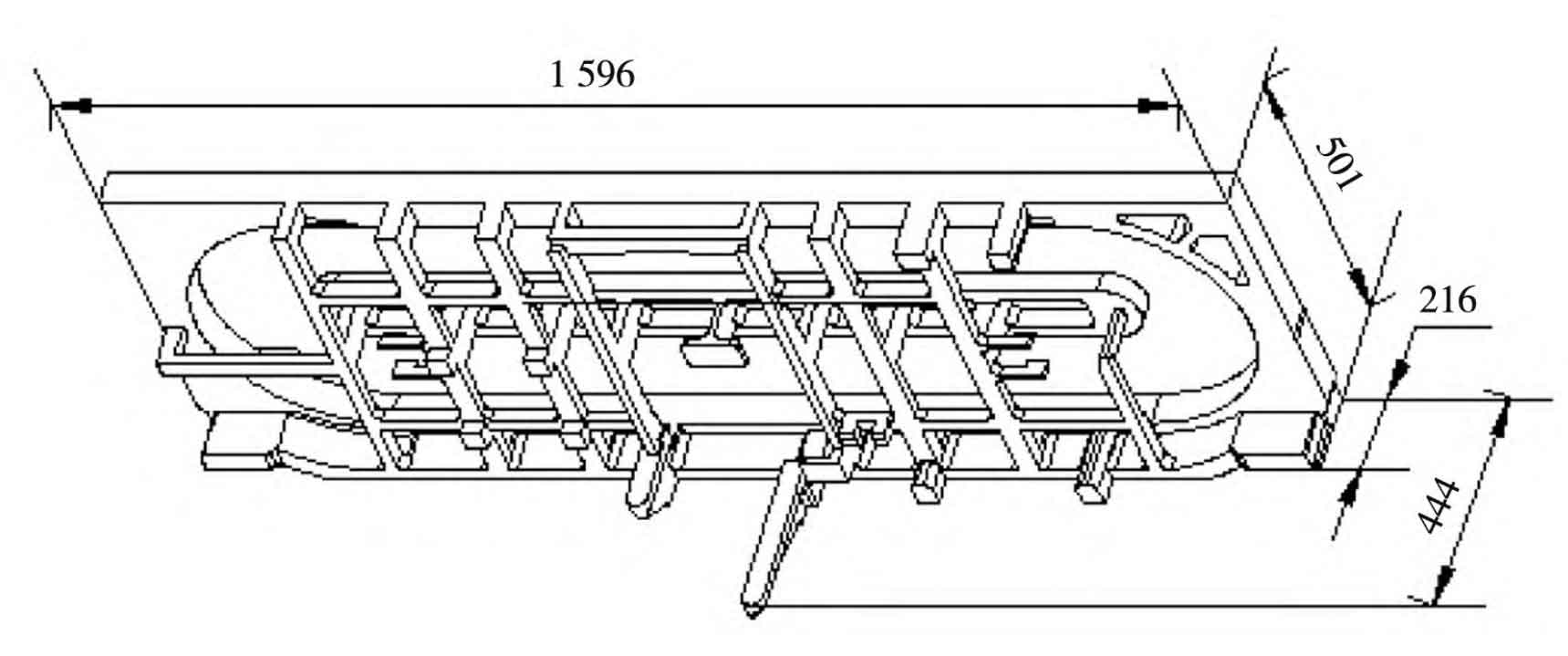

According to the structural characteristics of steel castings and previous production experience, the casting shrinkage in the length direction and width direction of the inner cavity is set to 1.8%, and the shrinkage in the height direction is set to 2%. Other dimensions marked with tolerances are made according to the median size to prevent dimensional tolerances.