Abstract

In the realm of lost foam casting (LFC), the 140 flywheel shell presents challenges like box lifting and iron inclusions. This article analyzes the causes of these defects and outlines a series of process improvements. By adjusting negative pressure values, applying optimized coating methods, and extending holding pressure duration, the defect rates were significantly reduced. The analysis culminates in a systematic approach to improve both casting efficiency and quality.

1. Introduction

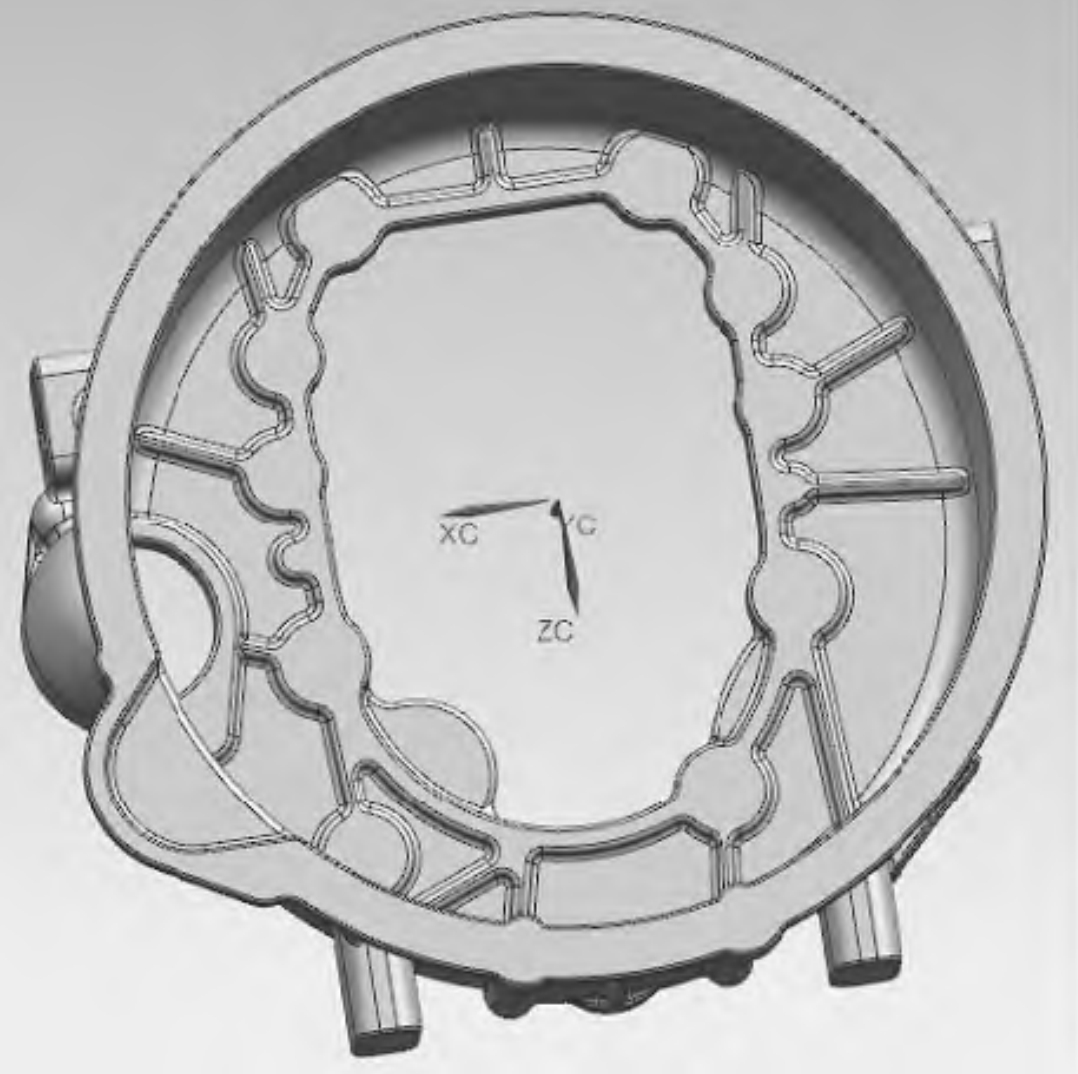

Lost foam casting is a modern manufacturing process, offering superior dimensional accuracy and internal quality compared to traditional sand casting methods. Despite its advantages, the lost foam casting process is not without defects, especially when dealing with large and complex castings. This article delves into the common defects encountered during the production of the 140 flywheel shell, including box lifting and iron inclusion, and explores the reasons for these issues.

2. Common Defects in 140 Flywheel Shell Casting

The primary defects observed in the casting process of the 140 flywheel shell are:

- Box lifting

- Iron inclusion

2.1 Box Lifting

Box lifting occurs when the negative pressure applied during the casting process is insufficient, causing the casting mold to lift or deform. For the 140 flywheel shell, which weighs approximately 32 kg and has a diameter of 450 mm with a wall thickness of 11 mm, the negative pressure value is crucial for successful casting.

2.1.1 Problem Description

Box lifting in the 140 flywheel shell leads to deformation of the part, making the circular surfaces oval-shaped, as seen in the figure below:

(Insert figure of box lifting defect)

When this happens, the machined part does not meet roundness tolerances, rendering it unusable.

2.1.2 Causes

The primary causes of box lifting include:

- Insufficient negative pressure

- Blocked filters in the sand mold

- Early closure of the vacuum during casting

2.1.3 Solutions

To address these issues, the following steps were implemented:

- Increase Negative Pressure: The negative pressure was increased to -0.025 MPa.

- Extend Pressure Holding Time: Pressure holding time was increased from 60 seconds to 75 seconds, eliminating the box lifting issue.

2.2 Iron Inclusion

Iron inclusion occurs when molten metal seeps through cracks or imperfections in the mold coating, leading to the formation of iron-sand combinations. The casting process of the 140 flywheel shell showed persistent iron inclusion defects during both small batch and large-scale production.

2.2.1 Problem Description

The iron inclusion defect typically manifests as small, block-like formations on the casting surface, complicating the post-casting machining process. The depth and distribution of these inclusions make cleaning difficult, as seen in the figure below:

2.2.2 Causes

The key factors contributing to iron inclusion are:

- High iron temperature

- Inadequate mold coating thickness

- Insufficient refractory properties of the molding sand

2.2.3 Solutions

Various strategies were employed to reduce iron inclusion:

- Increase Mold Coating Thickness: By adding additional layers of coating, the mold was better able to withstand the heat and pressure of the molten iron.

- Optimize Vibration Process: Adjustments were made to the vibration process to ensure the mold remained intact during casting.

3. Casting Process Optimization

3.1 Negative Pressure Adjustments

Initially, a vacuum pressure of -0.025 MPa was used, which led to significant defects. After testing, an increase in the negative pressure and extending the pressure holding time to 75 seconds improved the process.

| Process Parameter | Original Value | Optimized Value |

|---|---|---|

| Negative Pressure | -0.025 MPa | -0.035 MPa |

| Pressure Holding Time | 60 seconds | 75 seconds |

3.2 Mold Coating Improvements

The original process used a single coating layer, which was found to be insufficient. The optimized process involved two coating layers, with drying intervals to ensure a solid protective barrier against iron infiltration.

| Coating Parameter | Original Value | Optimized Value |

|---|---|---|

| Coating Layers | 1 | 2 |

| Drying Time | 12 hours | 24 hours |

3.3 Vibration and Compaction Process

Proper vibration ensures that the sand mold fills all voids around the foam pattern, preventing casting defects like iron inclusion.

| Vibration Parameter | Original Value | Optimized Value |

|---|---|---|

| Vibration Intensity | Medium | High |

| Vibration Duration | 10 seconds | 15 seconds |

4. Final Results

Following the implementation of the optimized casting process, the defect rate was reduced from 40% to less than 2%. The table below summarizes the key performance improvements.

| Defect Type | Initial Rate | Final Rate |

|---|---|---|

| Box Lifting | 40% | 0% |

| Iron Inclusion | 25% | 1.2% |

5. Conclusion

Through careful analysis of the casting defects in the 140 flywheel shell, process optimizations were implemented that significantly reduced defect rates. These improvements, including enhanced negative pressure control, mold coating, and vibration adjustments, have stabilized production and reduced waste.

The overall improvements in casting quality highlight the importance of continuous process optimization in manufacturing. By applying these principles to similar projects, manufacturers can improve both product quality and efficiency.

6. Recommendations for Future Work

Further research could focus on optimizing other aspects of the lost foam casting process, such as:

- Temperature control during casting

- Advanced materials for mold coating

- Automation in the compaction and vibration process

By exploring these areas, future advancements in lost foam casting technology can be realized.