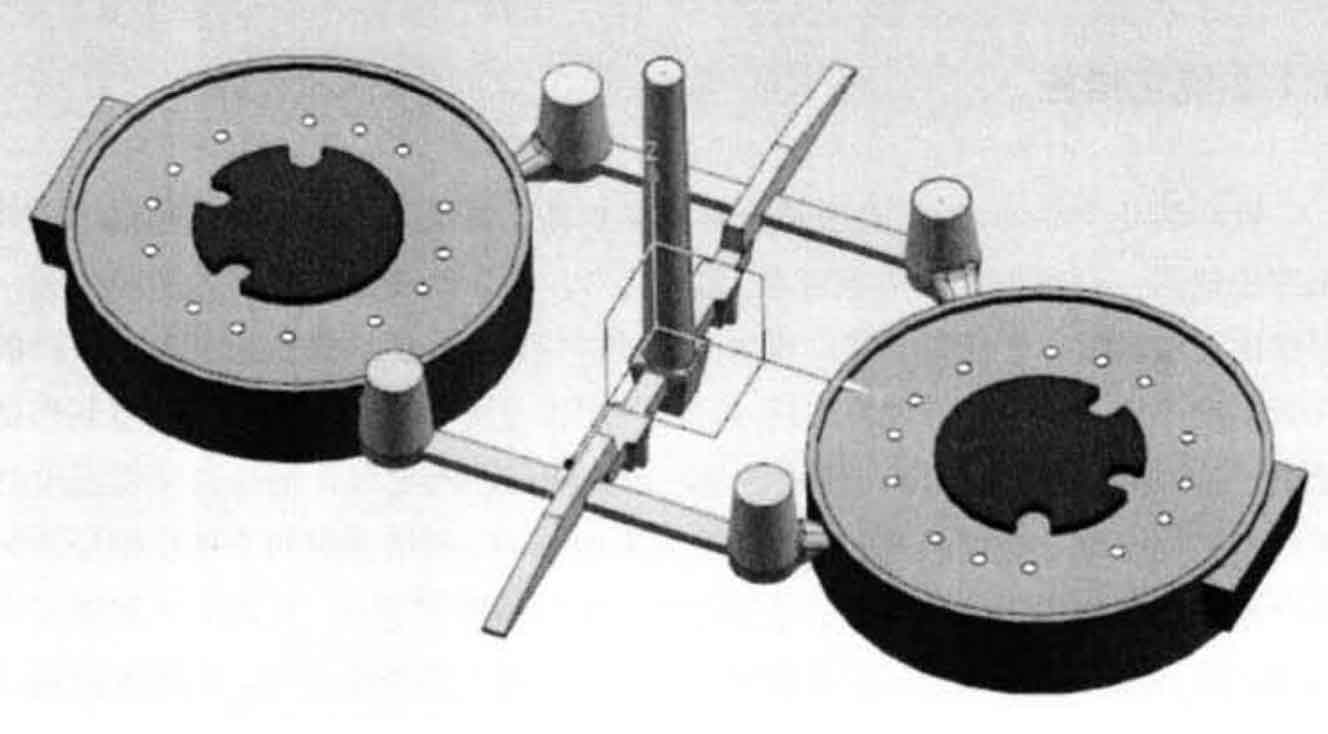

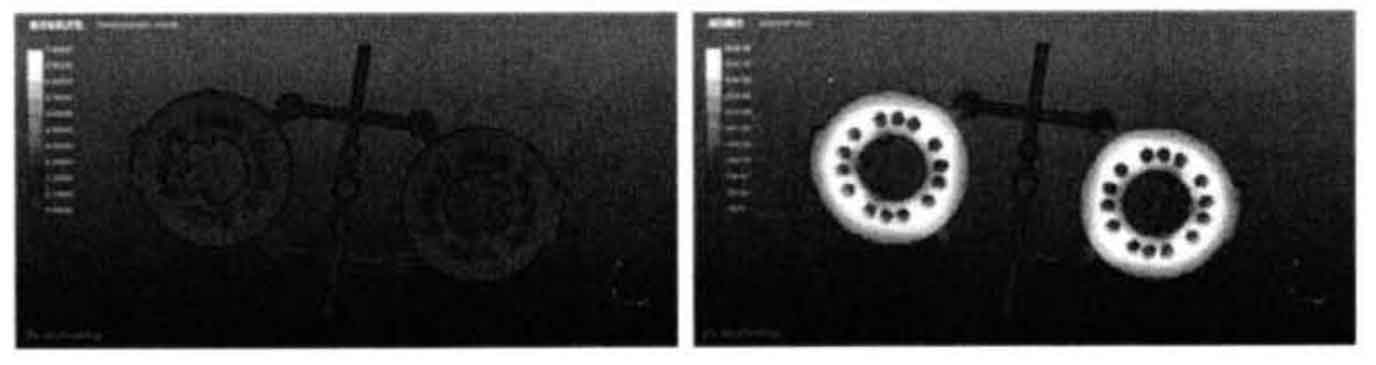

Considering the easy realization degree and economic factors of each measure, and using measures 2, 3 and 6, the numerical simulation of mold filling and solidification process is carried out again. That is, increase the length of inner sprue, rotate the cavity position of sand casting coupling parts by 180 degrees, and reduce the pouring temperature to 1400 degrees Celsius. Among these two optimization measures, 2 and 3 only need to slightly modify the tooling layout, and measure 6 only needs to change one parameter in the pre-processing stage of CAE simulation. Figure 1 shows the tooling after optimization, and the length of ingate is increased by 3 cm. Fig. 2 is the cloud diagram of shrinkage probability and solidification sequence of the cross section of the optimized shrinkage defect position.

By analyzing the optimized casting CAE simulation results, it can be seen from Figure 2 that although the defect area near the sprue is significantly reduced, the volume of the defect area at the far end of the sprue tends to increase, and there is also a high probability area of small volume shrinkage defects on both sides of the cavity, and the overall shrinkage volume is not improved and more dispersed. Compared with the solidification sequence of this section, it can be seen that the solidification time at the far end of the sprue is later than that under the original tooling layout. It is speculated that the reason is that under the existing parameters, the influence of the increased thickness of the part structure of sand casting coupling due to the rectangular boss and the three circular protrusions in the middle on the solidification time of this part is more obvious than that of turning away from the far end of the sprue and increasing the length of the inner sprue by 3cm. According to experience, the continuous increase of the length of the ingate has no material impact on the results. Therefore, in order to obtain sand casting coupling parts without shrinkage, it is necessary to further optimize the gating and riser system.