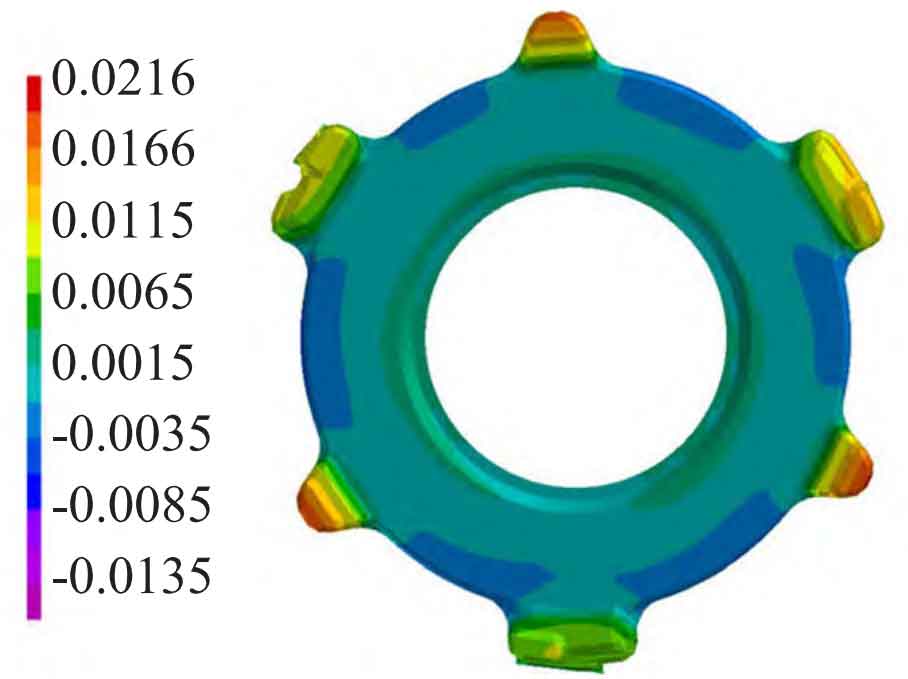

The flatness of compacted vermicular cast iron platen surface is also very high. Therefore, the deformation of compacted vermicular cast iron platen in Z direction (i.e. normal direction of platen surface) is mainly studied here. Figure 1 shows the deformation of vermicular cast iron pressure plate in Z direction (see electronic version for color map).

It can be seen from the figure that the processing surface of the vermicular cast iron pressure plate has different properties and sizes of deformation in the Z direction. The displacement near the outer circle (the blue part in the figure) is vertical to the outward face of the vermicular cast iron pressure plate (i.e. the negative direction of Z), and the displacement near the inner circle (the green part in the figure) is vertical to the inward face of the vermicular cast iron pressure plate (i.e. the positive direction of Z), which forms a phenomenon of outward convex and inward concave, As a result, the flatness accuracy of vermicular cast iron pressure plate surface is reduced. In order to deeply study the deformation of the pressure plate, some nodes are selected for research. The selected nodes require that they exist on the surface of the vermicular cast iron pressure plate and are on the same line, which can reflect the different deformation properties of different parts of the vermicular cast iron pressure plate. The selected points are shown in Figure 2, and the corresponding node displacement is shown in the table.

| Point number | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

| Displacement /10-3 cm | -1.4 | -1.0 | -0.4 | 0.3 | 1.08 | 1.78 | 2.5 | 2.18 | 1.58 | 0.74 | 0.07 | -0.41 | -0.78 | -0.83 |

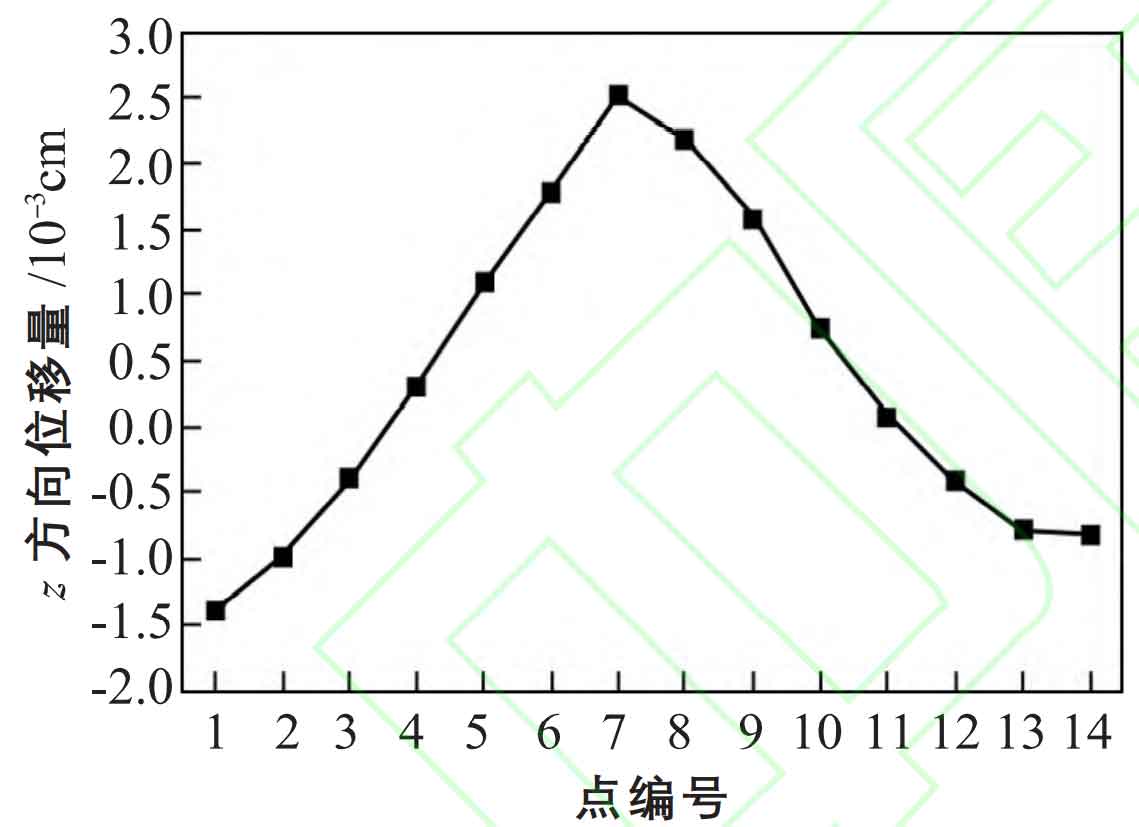

The 14 points selected in the figure are on a horizontal line, numbered from left to right as points 1 to 14, and the displacement of each point in the Z direction is shown in the table. The change curve of Z-direction displacement along the node is shown in Figure 3.

It can be seen from Figure 3 that the displacement of 14 nodes in the Z direction presents a symmetrical form, which corresponds to the strain diagram. The displacement of the points near the outer circle edge of the vermicular cast iron pressure plate is negative, that is, the deformation is outward convex, and the displacement of the points near the inner circle edge of the vermicular cast iron pressure plate is positive, that is, the deformation is inward concave, resulting in the reduction of the flatness accuracy of the whole vermicular cast iron pressure plate surface.