1. Molding process

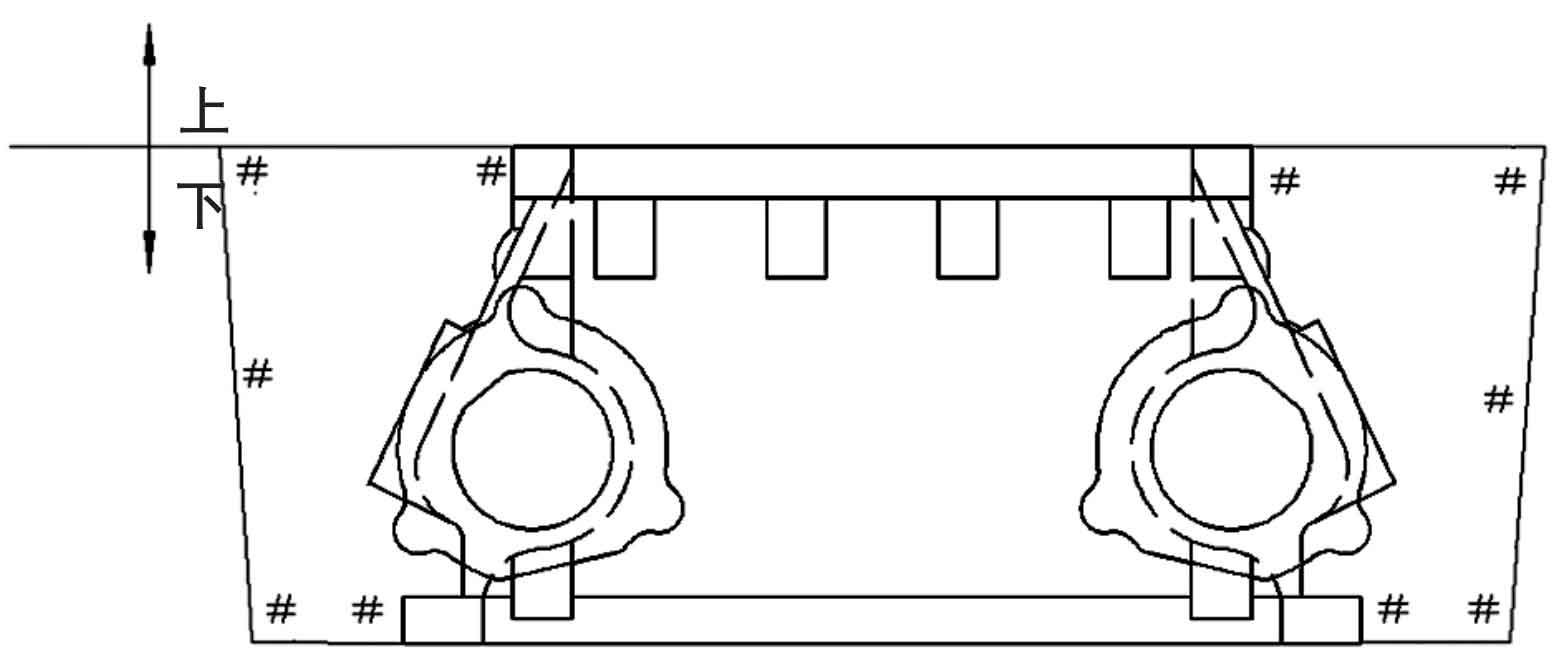

The two box core molding is adopted, and the sand filling core under the side molding is enlarged to the top surface of the nodular cast iron intercooler base pipe casting (Fig. 1). At the same time, in order to make full use of the existing sand box and simplify the mold structure, the lower molding pattern is only made to the center of the water pipe. After all the lower molding sand cores are laid, the middle sand box is sleeved, and the sand is filled on the back of the sand core, which not only simplifies the molding operation, And it can save the cost of mold making.

2. Gating system selection

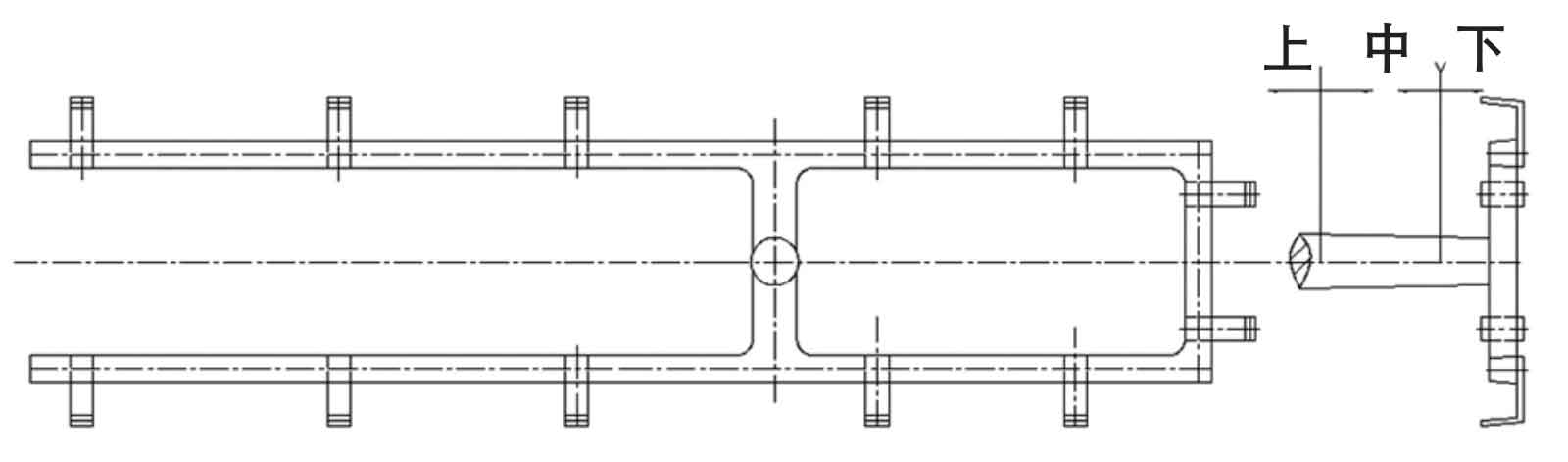

The intercooler base pipe has a large through hole. The gating system is set at the bottom of the inner cavity of nodular cast iron intercooler base pipe casting in the form of bottom return gating system (Fig. 2), in which ∑ f straight: ∑ f transverse: ∑ f inner = 1:1.85:1.19. The filling process is: the metal liquid enters the transverse sprue from the sprue, distributes to each inner sprue, and then enters the casting from the bottom of the nodular cast iron intercooler base pipe casting. The bottom return pouring system has the advantages that the runner is always full during the whole pouring process, even when the pouring flow is cut off, which can effectively prevent the slag from entering the mold cavity and prevent the slag inclusion defect; The molten metal enters the mold cavity from the bottom of the nodular cast iron intercooler base pipe casting, and the mold filling is stable without splashing and oxidation, so as to prevent the occurrence of iron beans and other defects; The sprue is set inside the nodular cast iron intercooler base pipe casting, and the flow distance of liquid metal in the mold is short, which can effectively reduce the defects such as cold clamp of nodular cast iron intercooler base pipe casting; The pouring system does not occupy the sand mold space, which can reduce the size of the sand box, reduce the amount of molding sand and reduce the production cost.

3. Error proofing design of sand core

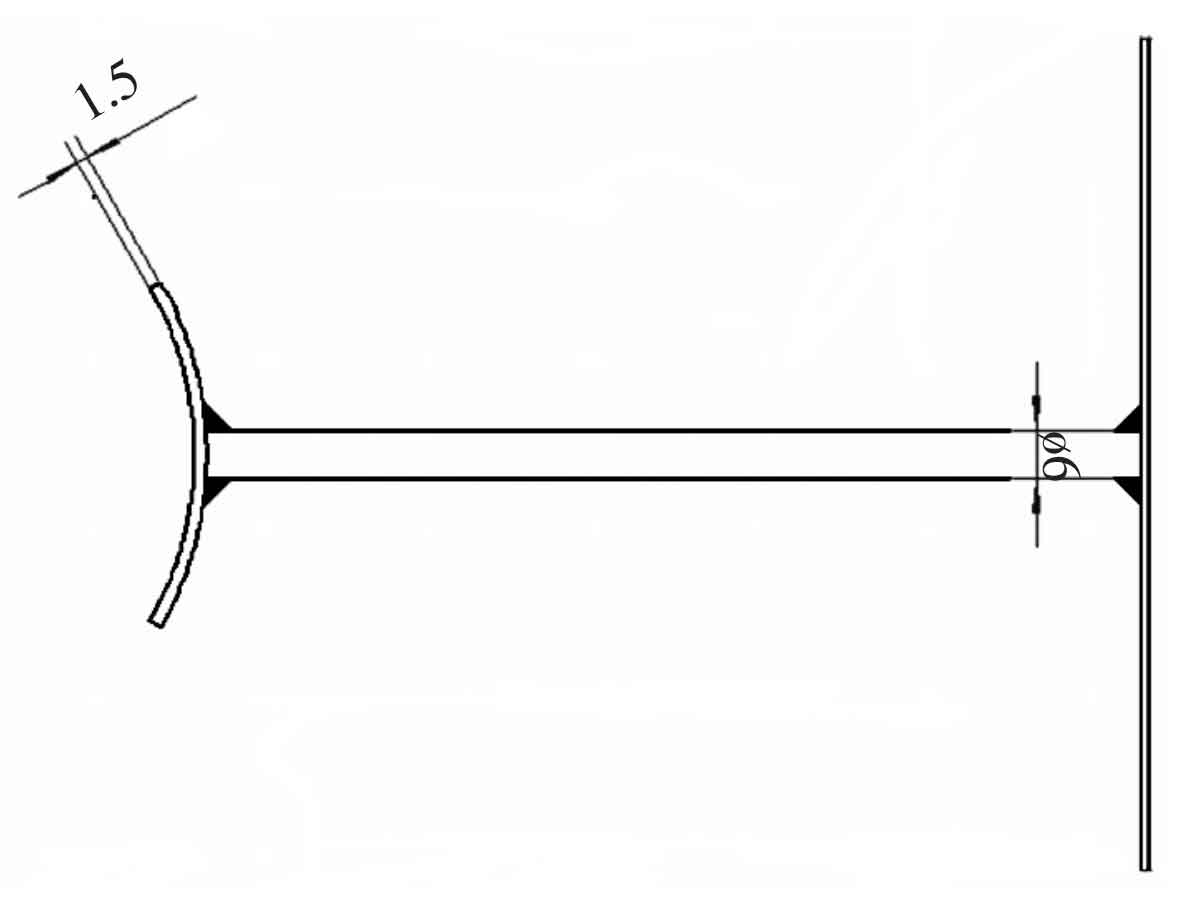

Due to the core modeling, the positioning is added between the upper and lower layers of the inner cavity sand core to ensure the accurate positioning of the sand core; The four sand filling cores on the side interfere with the water pipe cores on both sides when lowering the core, which cannot be lowered into the mold. The core base must be enlarged by 20mm to the rear and outside, and the fixed sand core shall be filled after lowering the core; The sand cores with the same side structure and similar structure are added with error proof design, that is, each sand core is designed with significantly different positioning devices, which can not be lowered into the mold in case of misoperation (Fig. 3), so as to effectively avoid the scrapping of nodular cast iron intercooler base pipe castings caused by the error of sand core.

4. Design of core support and cooling system

Change the thickness of the iron sheet on the supporting surface of the core support to 2mm, and the shape is consistent with the outer circle of the sand core (Fig. 3), so as to increase the stability of the sand core and ensure that the sand core does not float up under the action of liquid iron buoyancy. In order to speed up the solidification speed of local hot spots, cold iron is set at the thick lap of nodular cast iron intercooler base pipe casting to balance the solidification speed of nodular cast iron intercooler base pipe casting and prevent shrinkage and porosity defects after drilling.

5. Process implementation effect

The casting quality of intercooler base pipe produced by this process is significantly improved, and the defects such as slag hole and cold shut are completely eliminated. After machining and hydrostatic test, the shrinkage porosity and leakage defect rate are greatly reduced, and the scrap rate can be controlled below 3%; The workload of modeling and fitting is reduced and the production efficiency is improved.