1. Metallographic comparison

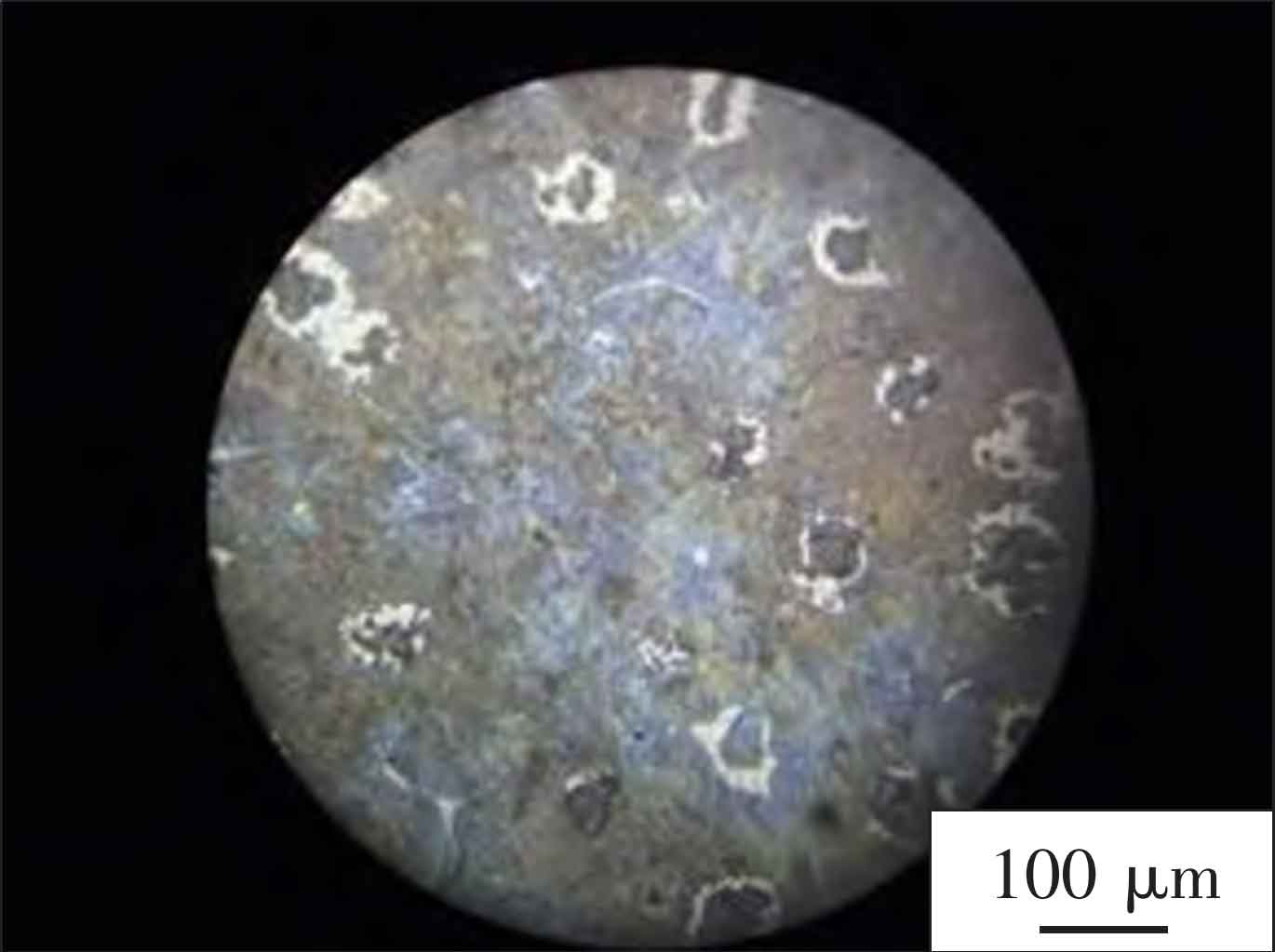

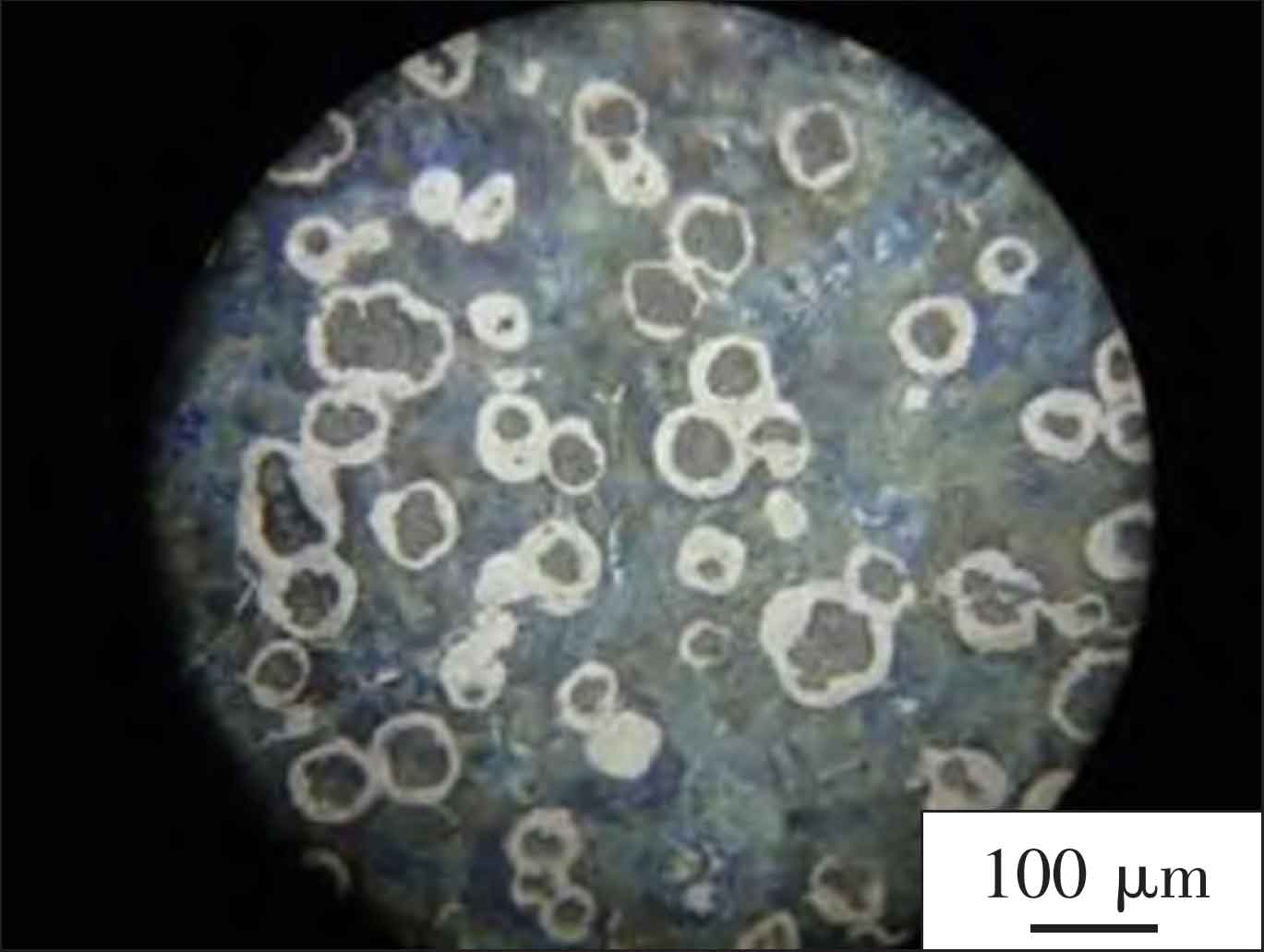

The metallographic structure comparison before and after the improvement of the process of producing nodular cast iron roll in the medium frequency furnace is shown in the figure. It can be seen that the graphite in the structure before the improvement is uneven, the graphite morphology is more clustered, the spheroidization rate is about 70%, and the ferrite volume fraction is low, which does not meet the upper limit requirements of the roll; After the process improvement, the graphite in the structure is evenly distributed, most of the graphite is spherical, the spheroidization rate can reach about 95%, and the volume fraction of ferrite is high, which meets the technical requirements.

2. Roll hardness and flaw detection

After the improvement of nodular cast iron roll produced in medium frequency furnace, there is no bottom wave attenuation in radial direction, the hardness meets the upper limit of 72~78 HSD requirements, and the wear resistance is good.

3. Mechanical properties

The test value of tensile strength of nodular cast iron roll diameter produced by medium frequency furnace is more than 520 MPa, which is 30% higher than the 400 MPa required by the user’s technical agreement before implementation.

4. Steel throughput

Steel rolling users adopt the optimized process to increase the steel passing volume of high nickel infinite roll for the production of nodular cast iron core from 3000 t to 3200 T, and the steel passing volume of high chromium cast iron roll for the production of nodular cast iron core from 4000 t to 4800 t.