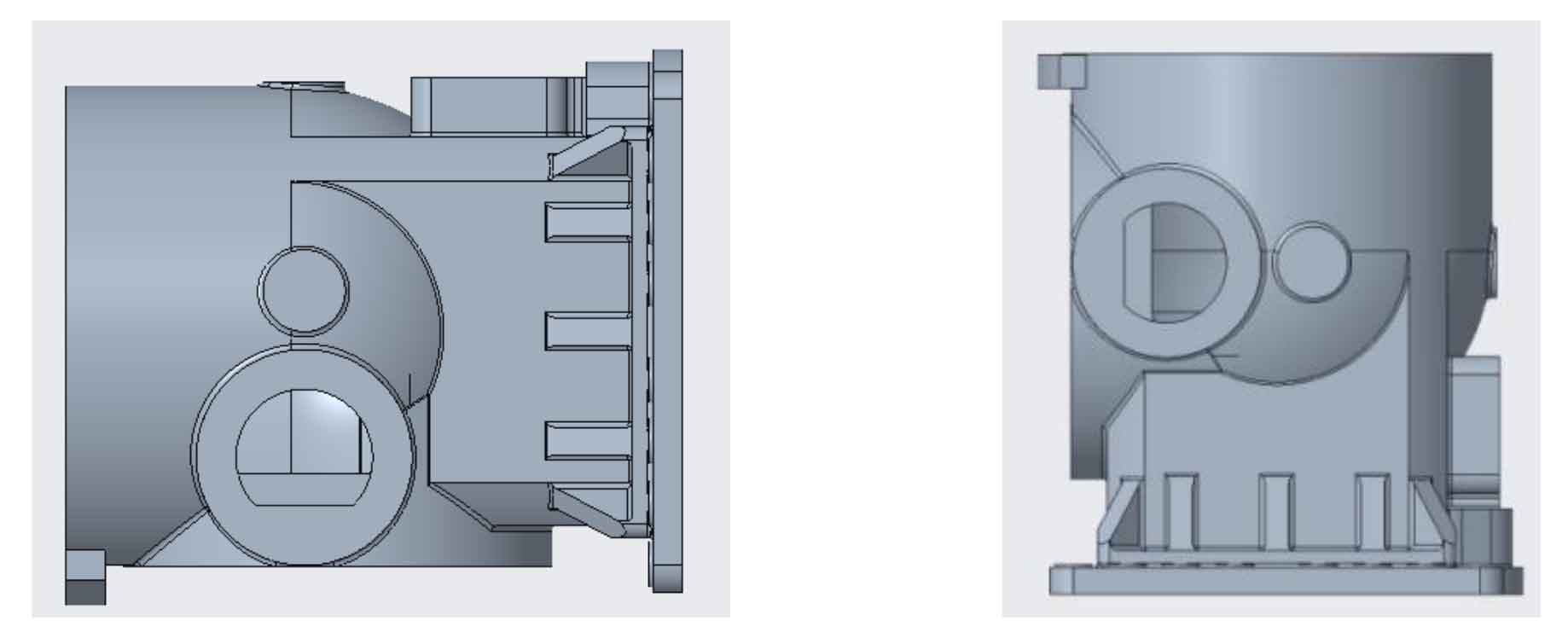

The pouring position of sand casting usually refers to the position of the axle housing in the mold during pouring. The pouring position is determined according to the structural characteristics of the axle housing, material characteristics, sand casting method and other relevant conditions. The correct pouring position can ensure the sand casting performance of the axle housing, and make the molding sand modeling, axle housing pouring, core sand core making, axle housing cleaning and cutting convenient. The pouring position of sand casting axle housing mainly includes the following two schemes, as shown in the figure.

According to the structural analysis of the part drawing of the axle housing, the important working positions of the axle housing are the flange surface and the circular hole in the inner cavity. Therefore, when designing the sand casting process, priority should be given to ensuring the accuracy of these dimensions and compact structure. At the same time, it should be considered that the uneven wall thickness of the axle housing is easy to produce heat joints. Therefore, when designing the sand casting process, The influence of pouring position on the possible sand casting defects of axle housing is comprehensively considered.

The pouring position scheme I is horizontally placed, as shown in figure (a). The gate position of the axle housing is located at the middle parting. This gate layout reduces the possibility of sand flushing of the axle housing, makes the liquid metal filling smooth and stable, and reduces a series of axle housing defects such as slag inclusion, entrainment and oxide inclusion; Strictly ensure the sand casting quality of important positions. While pouring at this position, the axle housing surface is completely at the parting surface, so it is easy to draw the mold and make the mold.

The pouring position scheme II is vertically placed, as shown in figure (b). The gate of the pouring system is located on the bottom flange surface, which is close to the axle housing. During the pouring process, liquid metal and molding sand are easy to wash, which is easy to cause sand casting defects such as sand washing, air entrainment and oxide inclusions, which can not ensure the sand casting quality of important parts, The parting surface has interference surface, so it is not conducive to draft and molding sand modeling.

To sum up, the pouring position of sand casting axle housing adopts the horizontal pouring position in scheme I in the figure.