Sand casting process parameters mainly include dimensional tolerance, linear shrinkage, draft angle and other aspects. The determination of these process parameters depends on the complexity of axle housing structure, axle housing design and existing process level, the accuracy and quality of molding tooling, the types of sand casting metal and alloy, and has an important impact on the shape and size control of axle housing.

1. Determination of tolerance zone

The dimensional tolerance of sand casting refers to the two allowable limit dimensional tolerances of the nominal size of sand casting.

The higher the requirements for the dimensional accuracy of the axle housing, the higher the requirements for the design level of the sand casting process, the performance and quality of the molding and core making materials, the equipment and tooling of the molding and core making, the heat treatment process, the cleaning quality, the management level of the sand casting workshop, and the production cost of the sand casting axle housing increases accordingly. Therefore, when determining the dimensional tolerance of the axle housing, we should not only ensure that the axle housing meets the requirements of processing, assembly and use, but also consider reducing the production cost.

According to the standard of gb6414-1999, the dimensional tolerance grade of sand mold casting is set as grade 16, and the code is divided into CT1 to ct16. According to the literature, the production process is sodium silicate sand casting, the dimensional tolerance of sand casting is ct12-ct14, and the machining grade of mechanical allowance is MAH.

2. Shrinkage of sand casting axle housing

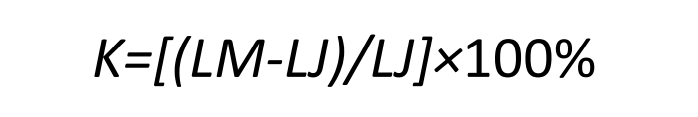

The linear shrinkage of sand casting axle housing has a great influence on the accuracy of axle housing size. The shrinkage of metal in liquid state is represented by the decrease of liquid level, which can only be expressed by the decrease of volume. Volume shrinkage can be supplemented by pouring and riser. It does not affect the final size of the sand cast axle housing. The linear shrinkage is irreparable. Only by accurately considering the shrinkage value can the mold size be enlarged in advance. The formula of sand casting shrinkage is:

Where:

LM — die working face size (mm);

LJ – dimension of sand casting axle housing (mm).

The correct selection of shrinkage in sand casting is very important, which will directly affect the dimensional accuracy of axle housing. The tractor split axle housing is made of zg40mn. According to the requirements of casting solidification theory, the shrinkage rate during liquid metal solidification is not greater than its free shrinkage rate. Considering the obstruction and part structure, the shrinkage rate of sand mold casting is taken as 2% according to table 2-3.

3. Sand core design

The sand core is designed to form the inner cavity, forming hole or part with complex shape that is not easy to start the mold of the sand casting axle housing. The shape of sand core of sand casting axle housing is relatively complex, and the wall thickness transformation difference is up to 14mm. It is required that the strength, fluidity and collapsibility of sand core are good, and it belongs to class III sand core according to the complexity.

According to the basic principle of sand core setting, minimize the number of sand cores, and set the parts with regular shape and easy sand filling in one sand core. When designing the sand core, we first need to design the sand core along the sand mold casting bridge shell structure.

The basic requirements of the sand core are that the shape, size and position of the sand core in the sand mold shall adapt to the requirements of the sand casting axle housing, with sufficient stiffness and strength. The gas generated by the sand core can be excluded from the mold in time during the solidification of the casting shell. The sand core will not give large resistance when the sand casting axle housing shrinks, so it is easy to remove the sand.

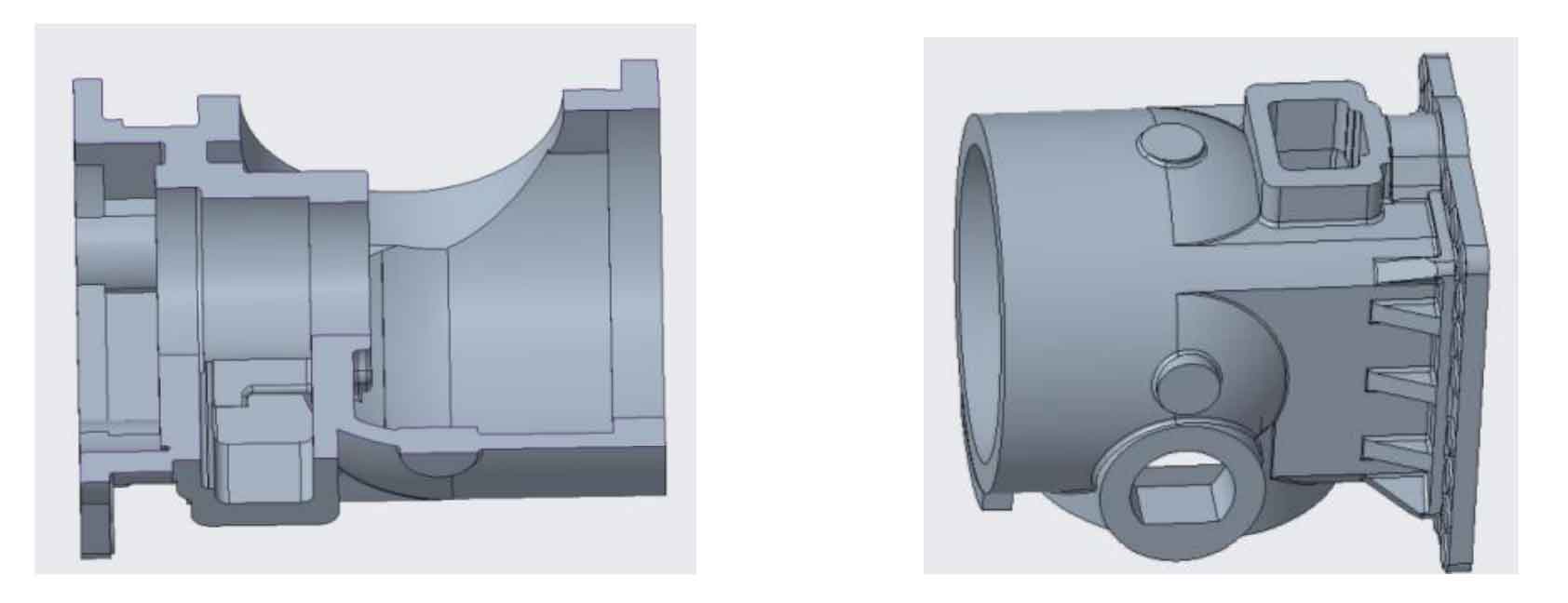

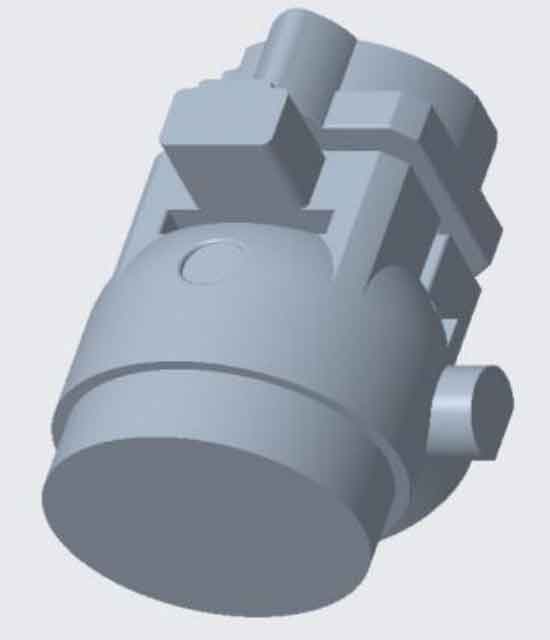

According to the three-dimensional drawing of sand casting axle housing and the structure of axle housing, there is only one mold cavity connected with each other. The lumen structure is shown in Figure 1. For sand casting axle housing, resin coated sand can be used for core making and modeling. It is necessary to design a core with horizontal core and vertical core.

The sand core is usually fixed in the mold by the core head. Some use other parts to fix the sand core, such as core support and bolts. In this design, the core head fixing method is proposed, and the sand core adopts cold core box sand core. The sand core contains a horizontal core head and a vertical core head.

The positioning of the sand core is relatively key, and the sand core is not allowed to move along or rotate around the core head; In this design, the sand core head is a circular structure of two vertical staggered core heads, which can accurately locate the position of the sand core in the mold, so it is not necessary to consider the horizontal movement and rotation of the sand core.

For the inner cavity size of the core head, the length of the left core head in the horizontal direction is 50mm, the length of the right core head is 50mm, and the inclination of the left and right core heads is 3 °; The length of the upper core head in the vertical direction is 50mm and the length of the lower core head is 30mm; The inclination of the lower core head is 1 °, and the inclination of the upper core head is 4 °. The length of the horizontal core head is 35mm by consulting relevant documents. The specific structure of the core head is shown in Figure 2.

4. Draft angle

When the sand casting axle housing itself does not have sufficient structural inclination, sufficient draft inclination of sand casting axle housing shall be given in the axle housing design or sand casting process design to ensure smooth mold lifting. It is usually formed by increasing the wall thickness of sand casting axle housing, increasing or decreasing the wall thickness of axle housing or reducing the wall thickness of axle housing. The draft angle shall not exceed the wall thickness tolerance of the axle housing.

According to the height dimension of the stiffener of the sand casting axle housing is 18 mm and the requirements of the draft angle of the sand casting, the draft angle of the sand casting axle housing is 3 °.