Lost mold casting has experienced the following three stages of development:

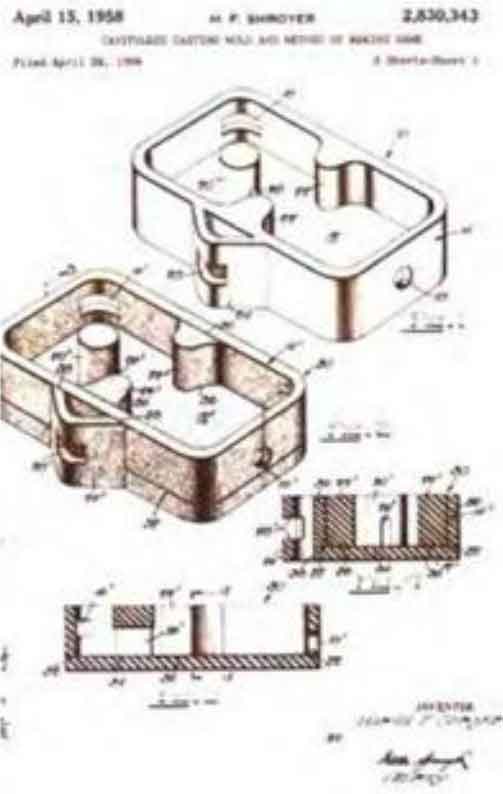

The first stage is the American H.F. Sloy (Shroyer) in 1956 invented the solid casting method, referred to as the F method. Its operation process is to make parts with foam shape, use sand with binder, and then cast into castings. Figure 1 is the principle diagram of solid casting method. In 1961, Professor A. Witmoser and several plastic companies, foundries jointly launched the solid casting technology and began to produce ordinary castings, until 1970, the United States used F method to produce 400,000 T castings.

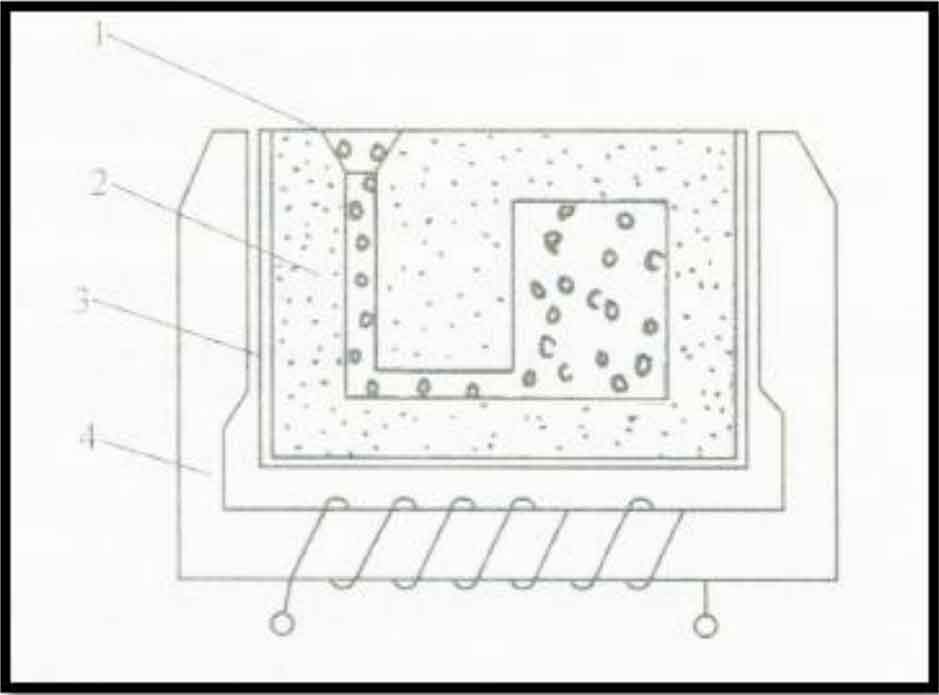

The second stage is dry sand solid casting technology. In 1964, German H. Nellen et al. used dry sand without binder to produce castings, but it often collapsed during pouring. Subsequently, R. Hoffmann from Germany proposed the principle of using magnetic field as binder on this basis and applied for the patent of magnetic casting, referred to as M-method casting, as shown in FIG. 2.

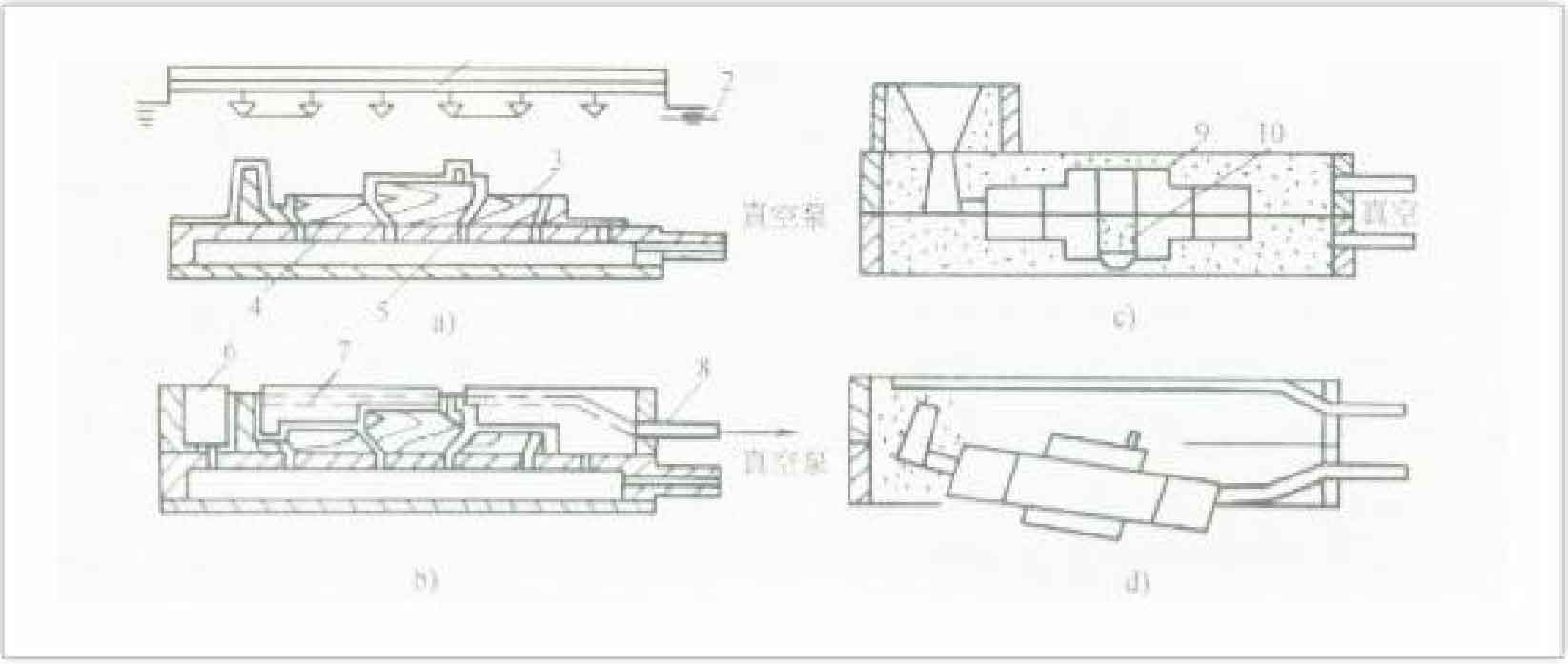

The third stage is developed on the basis of M method. Due to the limitations of M casting process itself, not only limit the size and shape of the product, but also the production and assembly of the appearance, coating and other processes are complex, the most serious is some casting defects (carburizing, pores, wrinkled skin, etc.) can not be solved. In 1969, Akita Corporation and Nagano Prefecture Industrial Testing Institute invented V-method casting (vacuum sealed molding method), referred to as V-method, and the schematic diagram is shown in Figure 3. The principle is to borrow plastic film and vacuum negative pressure compaction sand and forming, solve the M method casting collapse box problem, at the same time the process is simplified, not easy to produce pores, carburizing, wrinkled skin and other defects.

The advantages of the solid casting method (F), dry sand solid casting method (M) and vacuum sealed casting method (V) are combined to form a new molding casting technology — lost mold casting, which takes foam plastic as the shape, non-adhesive dry sand and vacuum tight dry sand modeling. In the mid 1970s, European and American countries (the United States, Italy, Britain, Germany, the former Soviet Union, etc.) and Japan have developed and put into production of epc production lines. After 1980s, with the failure of lost mold patent, lost mold casting (EPC) process has developed rapidly and has been widely promoted and applied in the world.