(1) Development of water-based quick drying and self drying casting coatings

The water-based casting coating has the advantages of low cost, safety, reliability and low toxicity compared with the alcohol based casting coating. It is the first choice for the development and promotion of green casting coating. However, there are still technical bottlenecks in the large-scale application of fast drying / self drying water-based casting coatings. Although the water-based quick drying and self drying casting coating has reduced the drying time and even realized the self drying of casting coating, its drying speed still has great room for improvement, and the service performance, moisture absorption resistance and gas evolution of casting coating still need to be further improved.

As the sand core casting coating gradually transits from alcohol based to water-based, and the drying process of casting coating gradually develops from coal-fired, gas or resistance, infrared oven drying to microwave drying. The disadvantages of the traditional drying method are that the short-time operation is uneconomical, the floor area is large, and the surface temperature of the sand core is high after drying. The microwave drying overcomes the above shortcomings, which can not only shorten the drying time, but also improve the strength of the water-based casting coating layer and resin sand.

(2) Non occupying casting coating

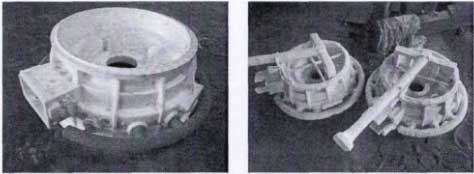

The non occupying casting coating, i.e. transfer coating, is that the casting coating is directly applied to the wall of the core box, hardened together with the sand core after sand filling, and the casting coating is transferred from the surface of the core box to the surface of the sand core during mold lifting. The casting coating does not occupy the effective space of the mold cavity, so the dimensional accuracy of the casting can be well guaranteed. The special coating process of the non occupying coating determines the particularity of its composition and performance. For example, the non occupying casting coating of the hot mold method is required to be coated on the hot core box. The bonding strength between the casting coating and the surface of the core box and the sand core determines whether the casting coating can be transferred, while the non occupying coating of the self hardening method requires that the casting coating can be self hardening without affecting the hardening of the interface sand core. Ordinary sand mold casting coatings can not meet the above requirements. Therefore, special non occupying casting coatings must be developed according to the specific process.

(3) Water based casting coating for precision molding sand mold

China’s precision molding process started late than foreign countries, and the corresponding research on precision molding casting coating lags behind. Precision casting coating technology belongs to the field of rapid casting, which is mainly used in precision casting, special casting, 3D printing casting and other fields. It is generally applied by dipping or spraying. Different from ordinary sand casting, the high-temperature permeability, metal permeability resistance and high-temperature thermoplasticity of casting coatings often can not meet the needs of precision molding, resulting in potential defects such as incomplete molding, casting adhesion and rough surface. The research on the special casting coating for precision casting process is of great significance for the promotion of precision casting and the realization of self-sufficiency of molding materials.