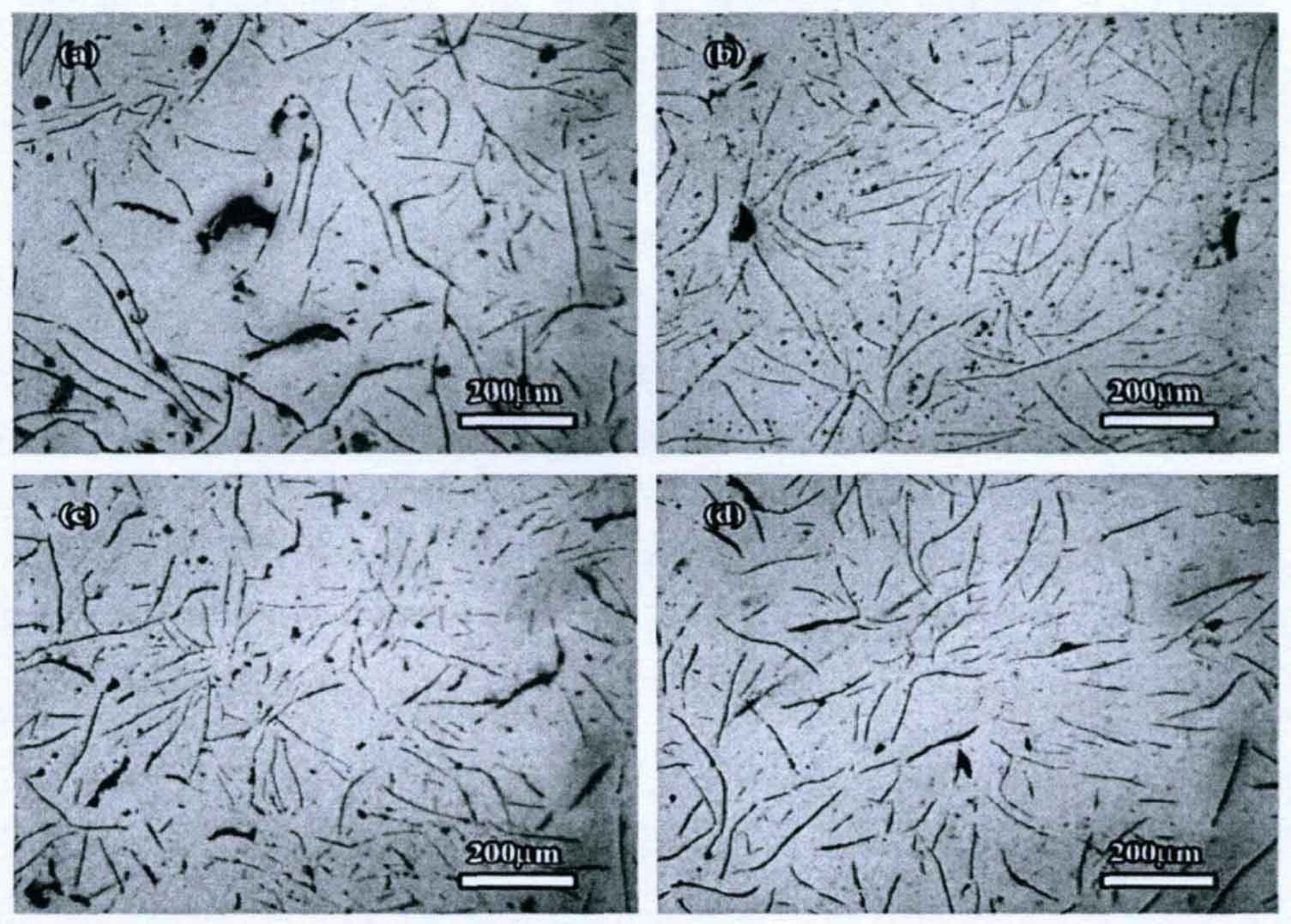

The figure shows the graphite morphology of gray cast iron prepared under different amplitudes. Figures (a) – (b) show the graphite morphology of gray cast iron prepared under the conditions of amplitude of 0.75, 2, 3 and 4mm respectively.

It can be seen from the figure that there is a small amount of C-type block graphite in the gray cast iron prepared when the amplitude is 0.75mm; When the amplitude increases, the length of A-type flake graphite becomes shorter. This is because the greater the amplitude, the greater the exciting force of the vibration on the metal melt, which is more conducive to the homogenization of the composition of the metal melt. According to the formula, it can be seen that the homogenization of metal melt composition reduces the driving force of graphite growth and is conducive to obtaining graphite sheets with smaller length. Therefore, the length of graphite becomes shorter.

| Amplitude /mm | 0.75 | 2 | 3 | 4 |

| Actual length of graphite /mm | 0.35 | 0.31 | 0.25 | 0.23 |

The table shows the results of statistical analysis of graphite parameters in the figure. It can be seen from the table that the length of graphite in gray cast iron decreases with the increase of amplitude. When the amplitude is 0.75mm, the length of graphite is larger, while when the amplitude is 4mm, the length of graphite is smaller. The length of graphite decreases with the increase of amplitude. The main reason is that the vibration force on the metal melt is greater with the increase of amplitude, which makes the solidification process of metal more affected by vibration.