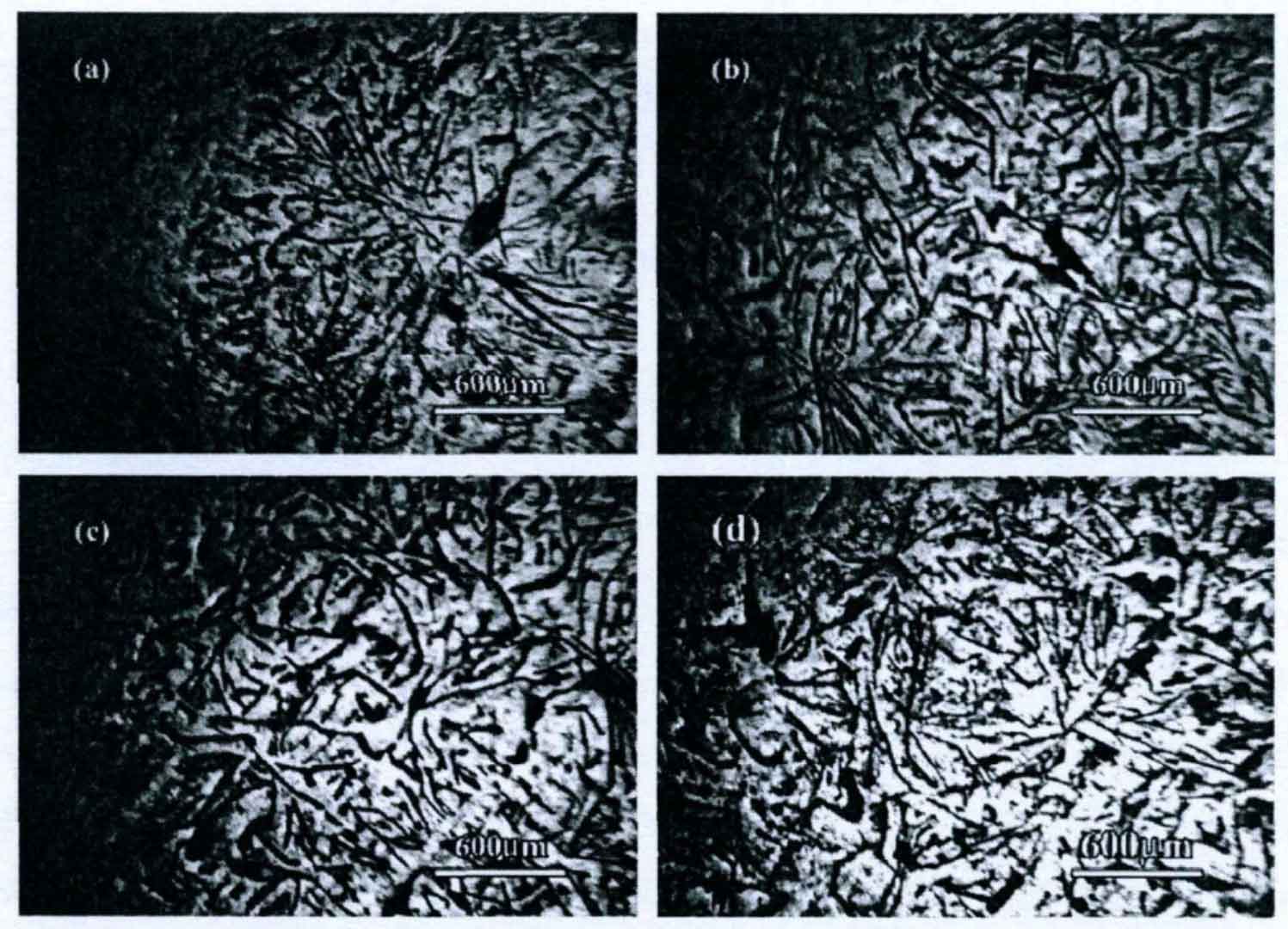

The figure shows the morphology of primary austenite of gray cast iron prepared under different amplitudes. Figures (a), (b), (c) and (d) show the morphology of primary austenite of gray cast iron prepared under the conditions of amplitude of 0.75, 2, 3 and 4mm respectively.

It can be seen from the figure that when the amplitude is small (0.75mm), the austenite dendrites of EPC gray cast iron are underdeveloped and the grain size is small. When the amplitude is 2mm, there is no obvious primary austenite dendrite in the austenite structure, the equiaxed dendrite in the alloy is more developed, the grains branch from the core to the outside, and the secondary arms are developed. When the amplitude is further increased to 3mm, there are a certain number of undeveloped primary dendrites and equiaxed dendrites in gray cast iron. When the amplitude is 4mm, the dendrite principal axis is short and thick, the secondary crystal arm is undeveloped, and the network frame structure is not formed.

Vibration makes the secondary austenite dendrite precipitated in the solidification process of gray cast iron subject to motion resistance and inertia force. Under the combined action of motion resistance and inertia force, the secondary austenite dendrite arm will break and the austenite grain size will be reduced. According to the formula, when other solidification conditions of gray cast iron are the same, the resultant force of motion resistance and inertia force on the secondary dendrite arm during movement increases with the increase of amplitude. It can be inferred that the greater the amplitude, the more obvious the effect of vibration on the fragmentation of austenite dendrites, and finally austenite with fine grains and undeveloped dendrite morphology is generated.

On the other hand, it can be seen from the above analysis that vibration will cause cavitation effect in the body of lost foam casting gray cast iron, forming a large number of holes. When the holes collapse, the metal melt around them will enter the holes and generate greater pressure. The pressure will increase the melting point of gray cast iron. The greater the amplitude, the greater the possibility of hole collapse, and the greater the pressure change in the museum. According to the Clapeyron equation, the melting point of gray cast iron increases with the increase of pressure change value. Vibration can increase the melting point temperature of the alloy, which is equivalent to increasing the average temperature of the alloy liquidus. When the metal solidification temperature remains unchanged, it is equivalent to improving the solidification undercooling of the alloy and further refining the size of austenite.

However, the experimental results show that the austenite grains of gray cast iron do not gradually refine with the increase of amplitude, and its microstructure presents more complex morphological characteristics. This may be related to the remelting of the smaller dendrite arms in the alloy. When the smaller dendrite arms rub laterally, the dendrite arm spacing increases and the austenite dendrites coarsen.