The austenitizing and isothermal transformation treatment was carried out on several samples taken from Φ 50 mm ductile iron test bar. T γ was 920 ℃, t γ was 1 h and 2 h, TA was 280 ℃, 330 ℃ and 380 ℃, and TA was 1.5h. Fig. 1 shows the microstructure of ADI obtained under different austempering process parameters. The matrix structure is composed of graphite ball, austenite and massive high carbon austenite. At the same time, with the increase of TA, the acicular ferrite structure becomes coarser and the amount of massive high carbon austenite increases significantly.

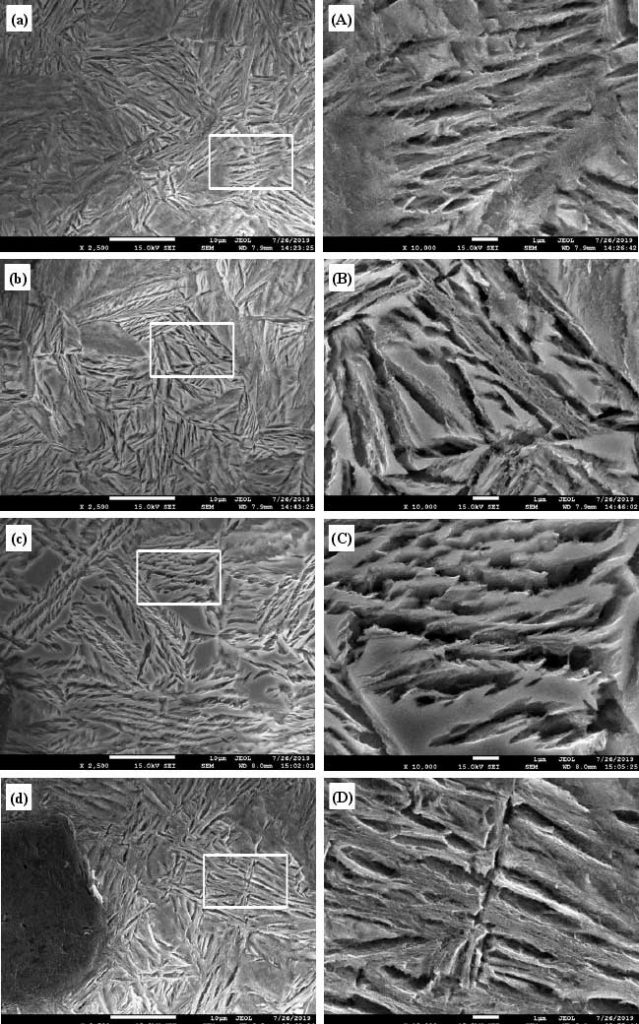

Fig. 2 shows the secondary electron image of ADI matrix under different austempering parameters. It can be seen from the figure that the ADI matrix structures obtained at 280 ℃, 330 ℃ and 380 ℃ are respectively austenite, ferrite + strip austenite, and austenite + strip austenite + massive austenite. When t γ is 920 ℃, the austenite microstructure is much shorter than that obtained by holding for 2h.

On the one hand, high isothermal transformation temperature reduces the nucleation rate of ferrite and enhances the diffusion activation energy In the subsequent isothermal transformation process, ferrite will nucleate and grow at the austenite grain boundary or graphite ball / austenite grain boundary, and terminate near the acicular phase boundary. The austenite grain size after austenitizing will determine the length of acicular ferrite after isothermal transformation.

However, when t γ is too short, the as cast microstructure cannot be transformed into uniform austenite structure, which will affect the subsequent transformation reaction of austenite. In addition, a bunch of austenite and ferrite sheets are observed under the conventional optical microscope, which are composed of high carbon austenite sheets and ferrite sheets whose orientations are generally parallel or the orientation angle is about 20 ° to 25 ° and the high carbon austenite sheets and ferrite sheets are refined to a certain extent with the decrease of TA. At the same time, the ADI matrix obtained by isothermal transformation at lower temperature (280 ℃, 330 ℃) has a cluster of ultra-fine austenite with a thickness of about 1 μ m, which increases with the decrease of isothermal transformation temperature.