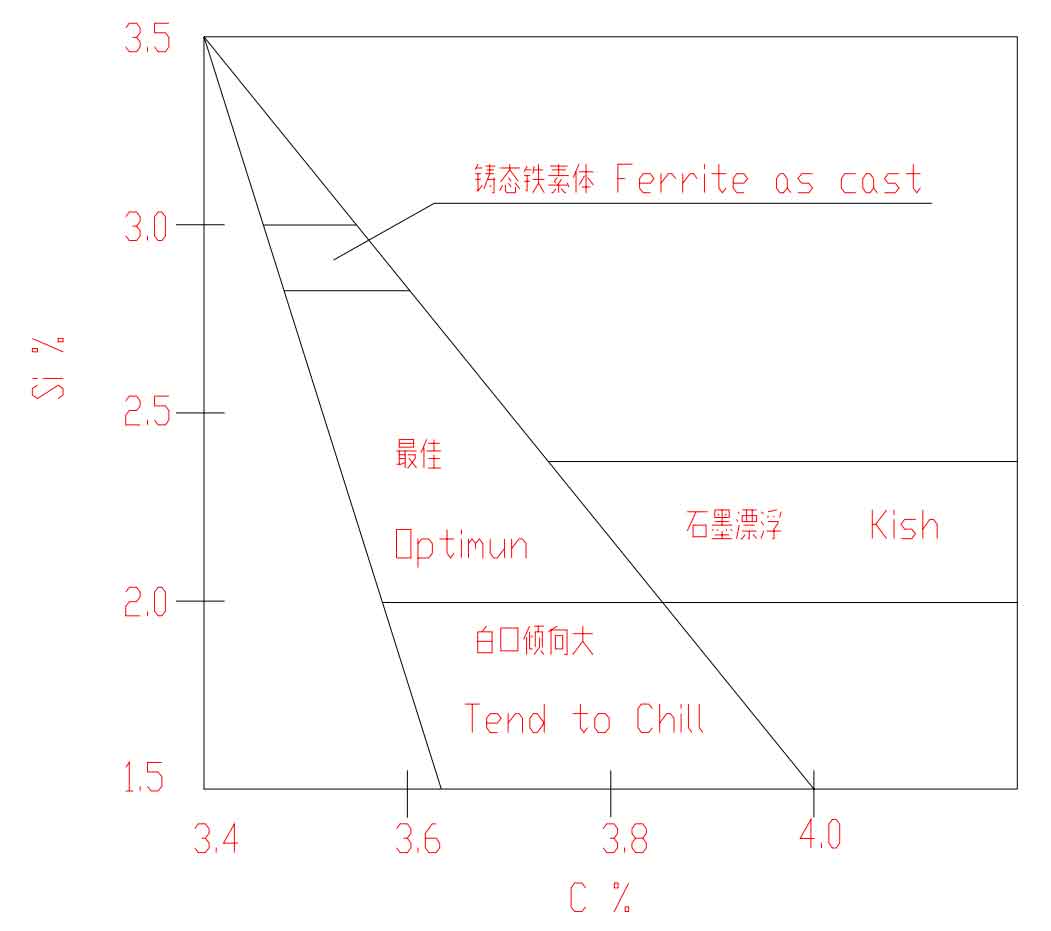

The influence of carbon and silicon content on the quality of nodular iron castings is shown in the figure below:

It can be seen from the figure that the optimum carbon and silicon contents of nodular iron castings are 3.4-3.85% C and 2.0-2.75% Si respectively, and the carbon equivalent CE = 4.4-4.55%. In this range, the fluidity of molten iron is the best, and the volume expansion during solidification is also large (at this time, pay attention to the rigidity of the mold). When the carbon equivalent decreases to about 4.3%, the tendency of shrinkage porosity and shrinkage cavity increases; With the increase of carbon equivalent, the secondary graphitization expansion increases, the “self feeding” ability of nodular iron castings increases, and the shrinkage porosity tendency decreases; However, when the carbon equivalent exceeds 4.6%, it is easy to produce black spots (graphite floating) defects.

For the production of pearlitic ductile iron and Ferritic Ductile Iron, the optimum carbon content is as follows:

Pearlite ductile iron: 3.4-3.7% C; Ferritic Ductile Iron: 3.5-3.85% C.

For the understanding of silicon, through literature introduction and process test, it is considered that silicon promotes graphitization, and its effect is more significant when added in the form of inoculant. The final Si is controlled in the range of 2.0-2.75% Si, but low Si should be used during smelting (the Si content of high-strength Pearlite Nodular Iron is 1.0-1.5% Si; the Si content of ferrite nodular iron is 1.5-2.0% Si), and the balance should be added during inoculation.